3DViewStation Desktop Viewer

Fast, universal 3D CAD viewer for use on desktop PCs, notebooks and Windows tablets.

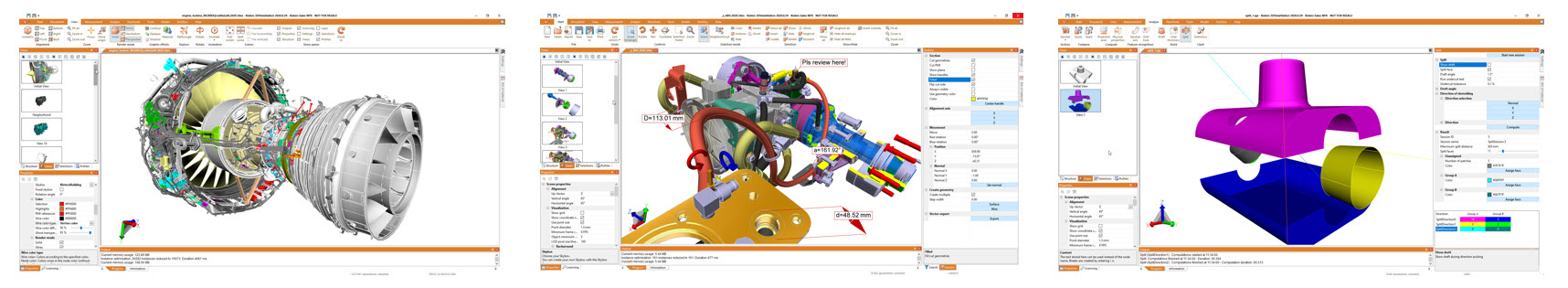

The 3DViewStation Desktop version is our most popular product. The Desktop viewer will be installed on your local PC and can very quickly visualize over 60 data formats from the areas of 3D CAD, 2D CAD, images and Office. In addition to pure viewing, many functionalities are available. These are navigation, selection, search & filter, measuring, dimensioning, cutting, comparison. But also advanced Digital Mockup, redline/markup, exploding, volume calculation, preparation for meetings, intellectual property protection, content generation for technical documentation and much more. With our Desktop viewer you can add CAD data from various CAD systems to a model - simply via drag & drop, without preparation. We call that real Multi-CAD DMU (Digital Mockup). The 3DViewStation Desktop version can work on its own (as a stand-alone), or: thanks to APIs it can also integrate into any leading system.

We would be happy to advise you

Sales Germany

+49 2408 9385 517

Sales USA

+1 916 723 1441

The 3DViewStation Desktop version at a glance

Desktop viewer

- The classic for local use

- Reads over 60 data formats

- 180+ functions from simple visualization to advanced analysis and Digital Mockup

- Extremely fast Desktop viewer

- Simple operation

- 3D CAD viewer for true Multi-CAD DMU

- Desktop viewer for small, medium and large manufacturing companies

- The Desktop viewer is also ideal for power users and travelers who need to work with local data

- Extension with plugins possible

Supported processes

- Project Reviews

- Sales

- Work preparation

- Work instructions

- Assembly instructions

- Manufacturing

- Engineering

- Change management

- Purchasing

- Marketing

- Technical documentation

- Repair instructions

- Service

- Quality assurance

- Collaboration

Possible applications

- Desktop PC, Notebook, Windows Tablet

- local installation

- also runs on virtual machines (VMs)

- runs alone (Stand Alone)

- running integrated

- Fixed or floating (network) licensing

- Single seat licensing, enterprise licensing

6 reasons why you should use the Kisters 3DViewStation Desktop viewer as your visualization tool:

- This 3D CAD viewer also runs on business notebooks with onboard graphics cards and even without graphics card

- The Kisters 3DViewStation Desktop version supports many data formats

- The Kisters 3DViewStation Desktop viewer is extremely fast

- The Desktop version of the Kisters 3DViewStation has a rich functionality, from simple viewing to meeting or shop floor preparation, authoring of change requests, work instructions or technical documentation and high end Digital Mockup

- The Kisters 3DViewStation Desktop viewer is still easy to use

- The Kisters 3DViewStation Desktop version can be integrated into any leading system, such as a PLM system

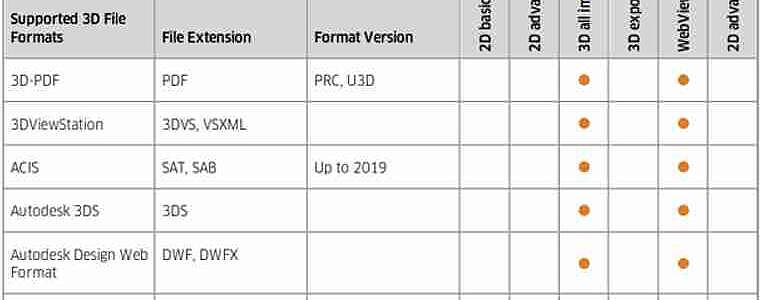

File formats

Import & Export

- 3D import - native & neutral CAD:

Catia, NX, Creo, Solidworks, SolidEdge, Inventor, SAT, Parasolid, JT, STEP, 3D PDF, Revit, GLTF, 3DXML, STL, VRML.. - 2D import - drawings, office, pictures:

Catia CatDrawing, NX 2D, Creo DRW, Solidworks slddrw, DWG, DXF, HPGL, 2D PDF, TIFF, JPEG - 3D export:

STEP, JT, 3D PDF, 3MF, Parasolid, STL,VRML - 2D export:

DXF, PDF, CGM, PNG, SVG, BMP..

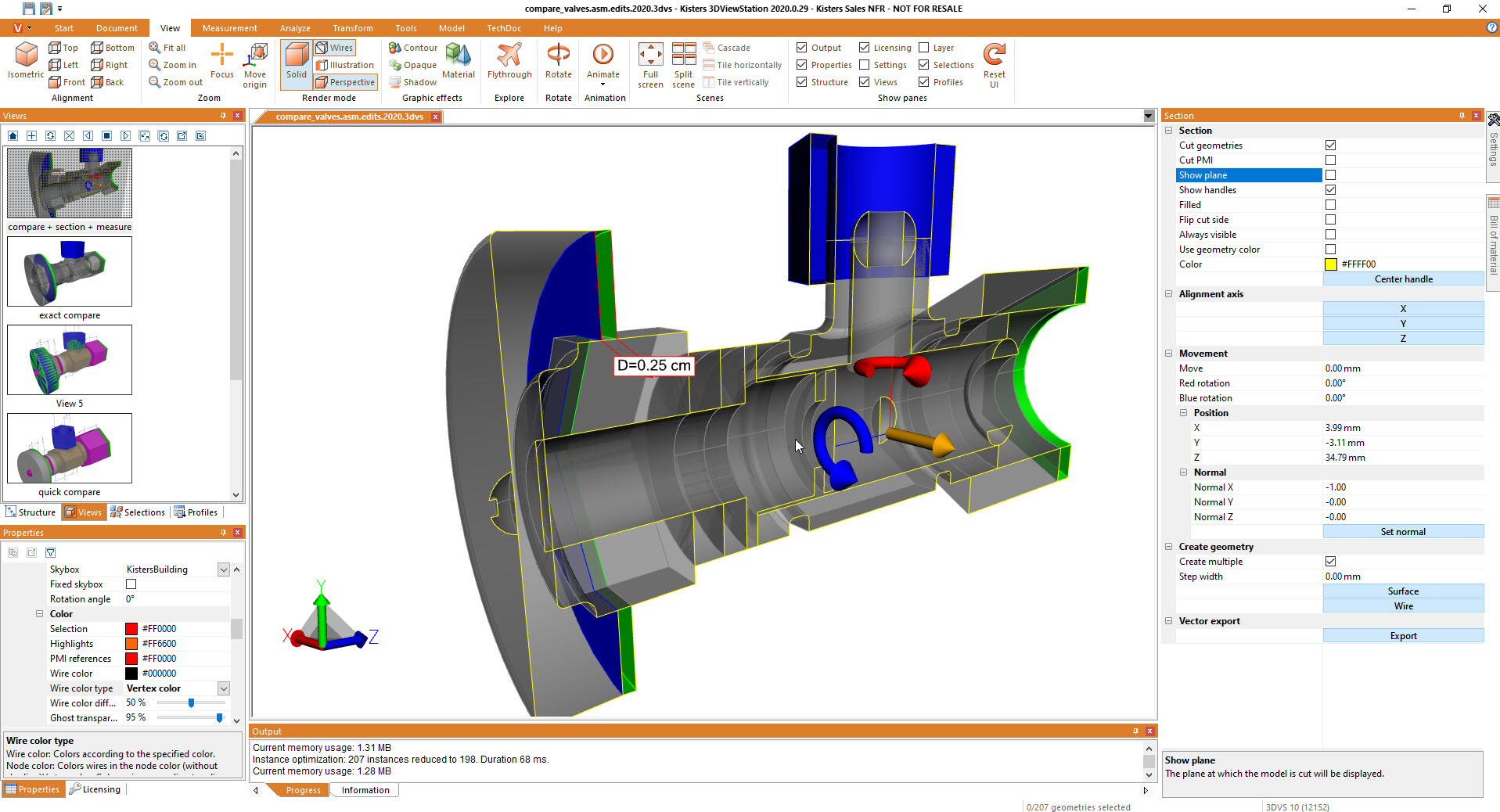

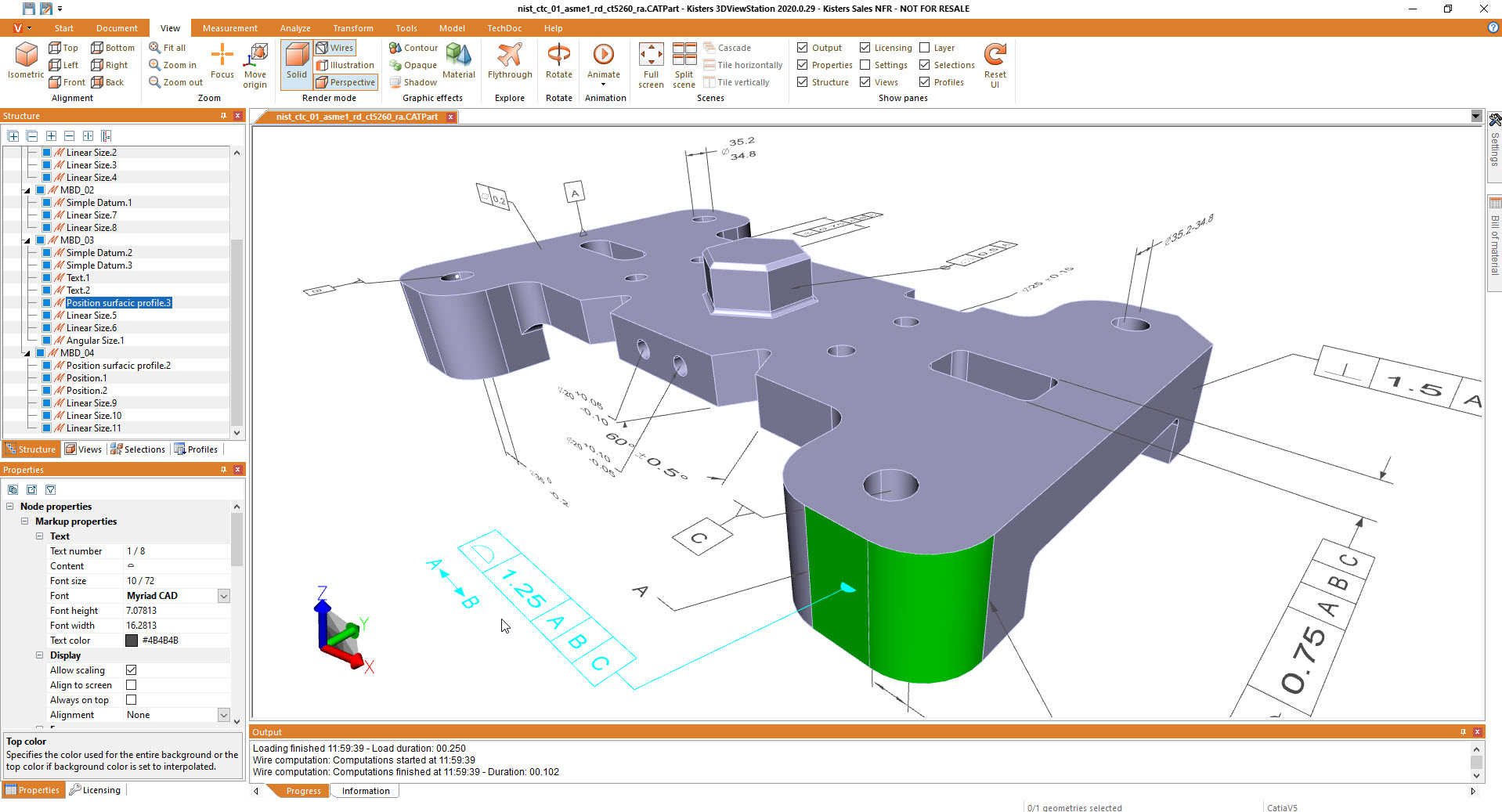

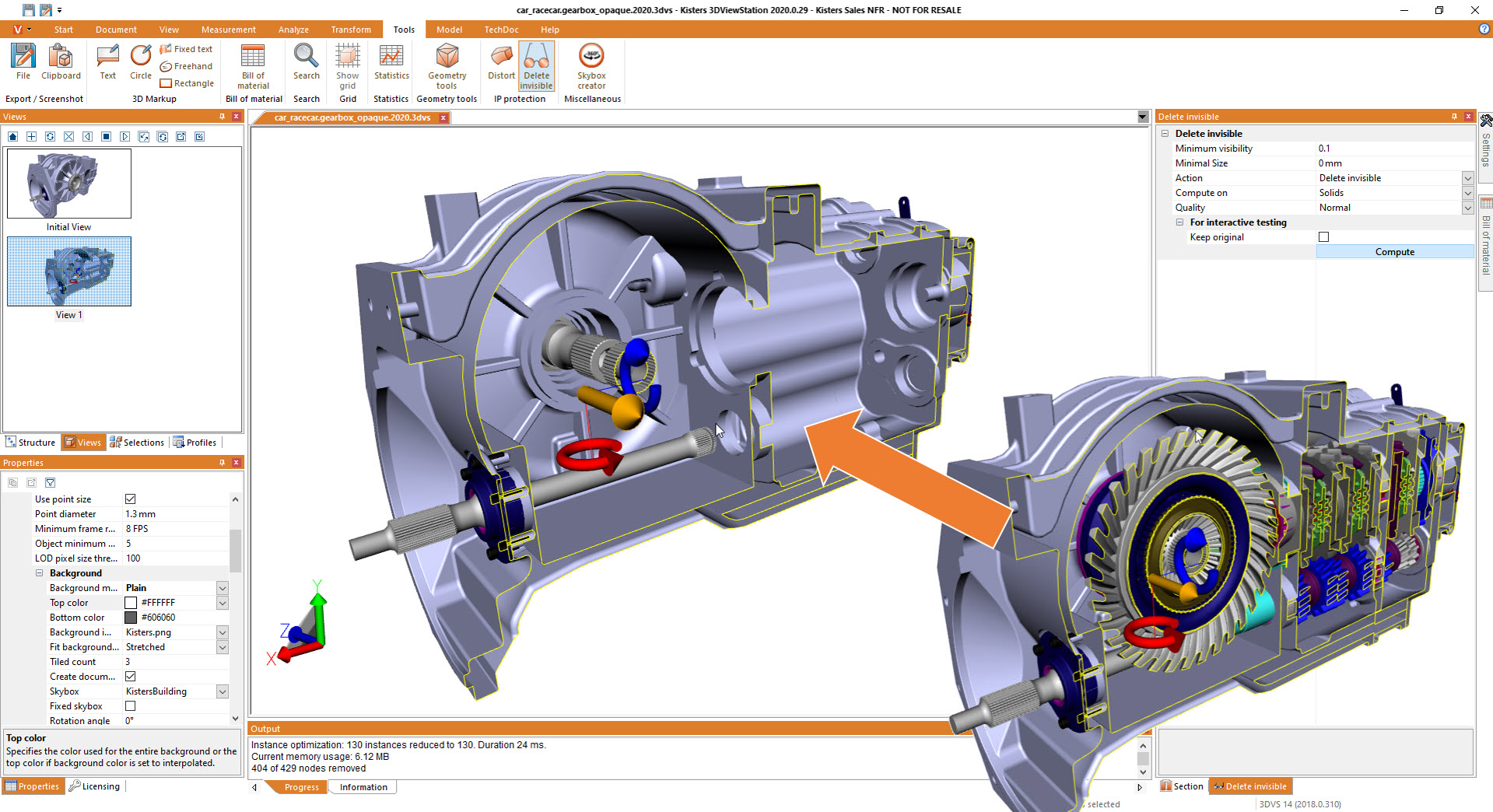

Functionalities

CAD Viewer / DMU Functions

- Navigate, select

- Search & Filter

- Measure & Dimension, Cut, Compare

- PMI / MBD support

- Rendering modes, set color, set transparency

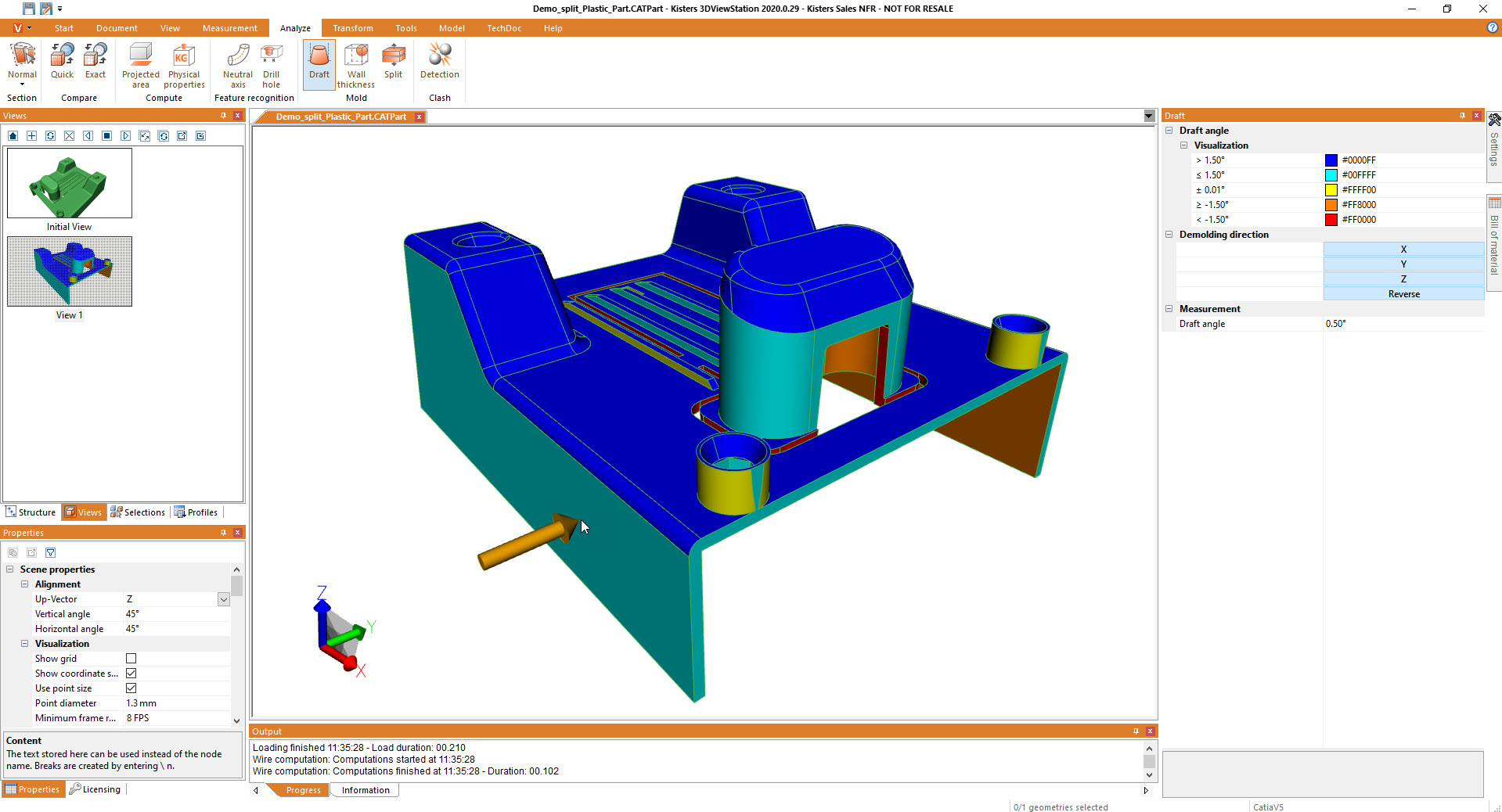

- Wall thickness, draft angle, split

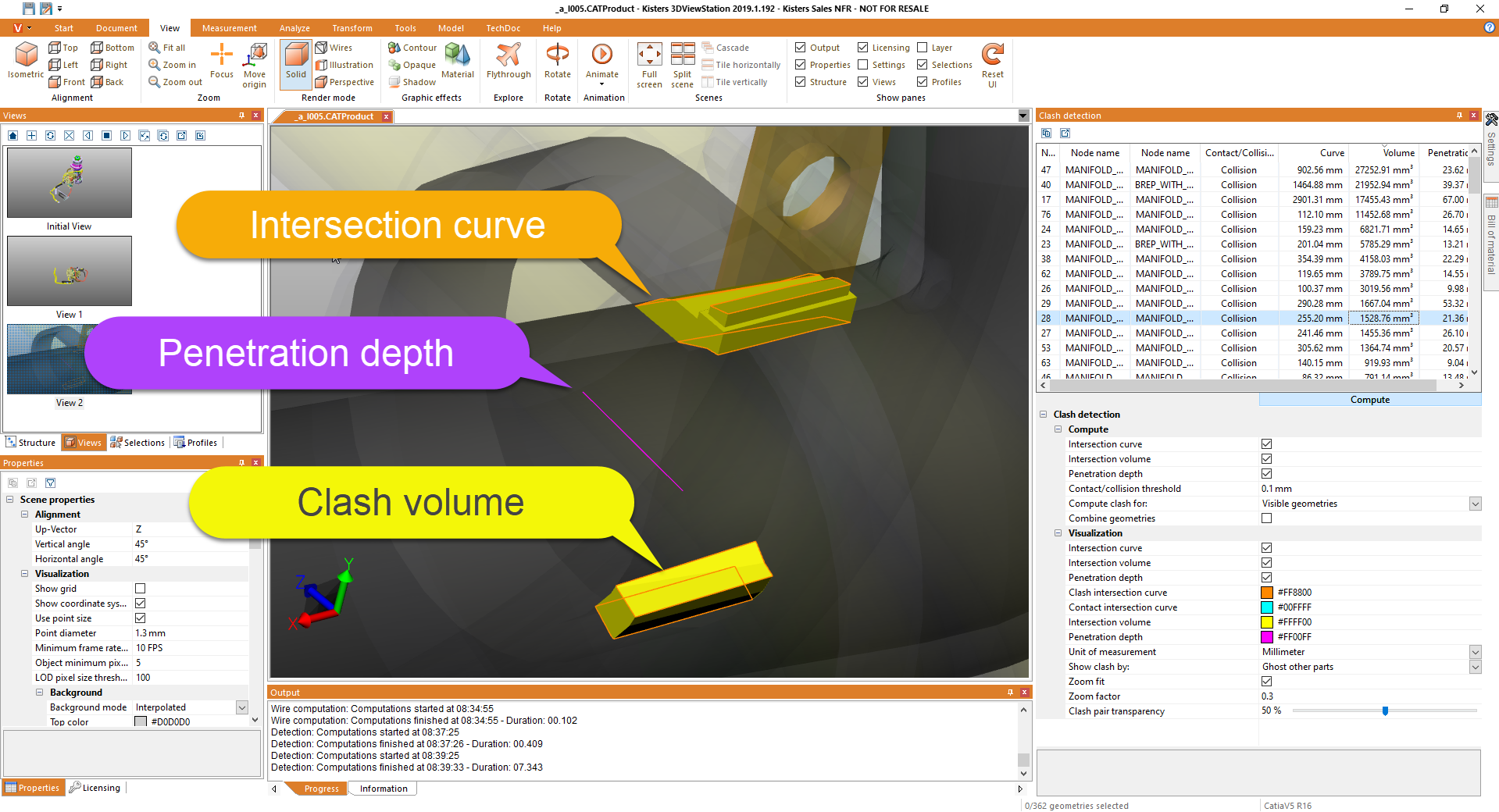

- Clash, clearence, distance bands

- Digital Mockup (DMU)

- Move, rotate, scale

- Best fit: auto align 2 solids

- Auxiliary constructions

- Properties

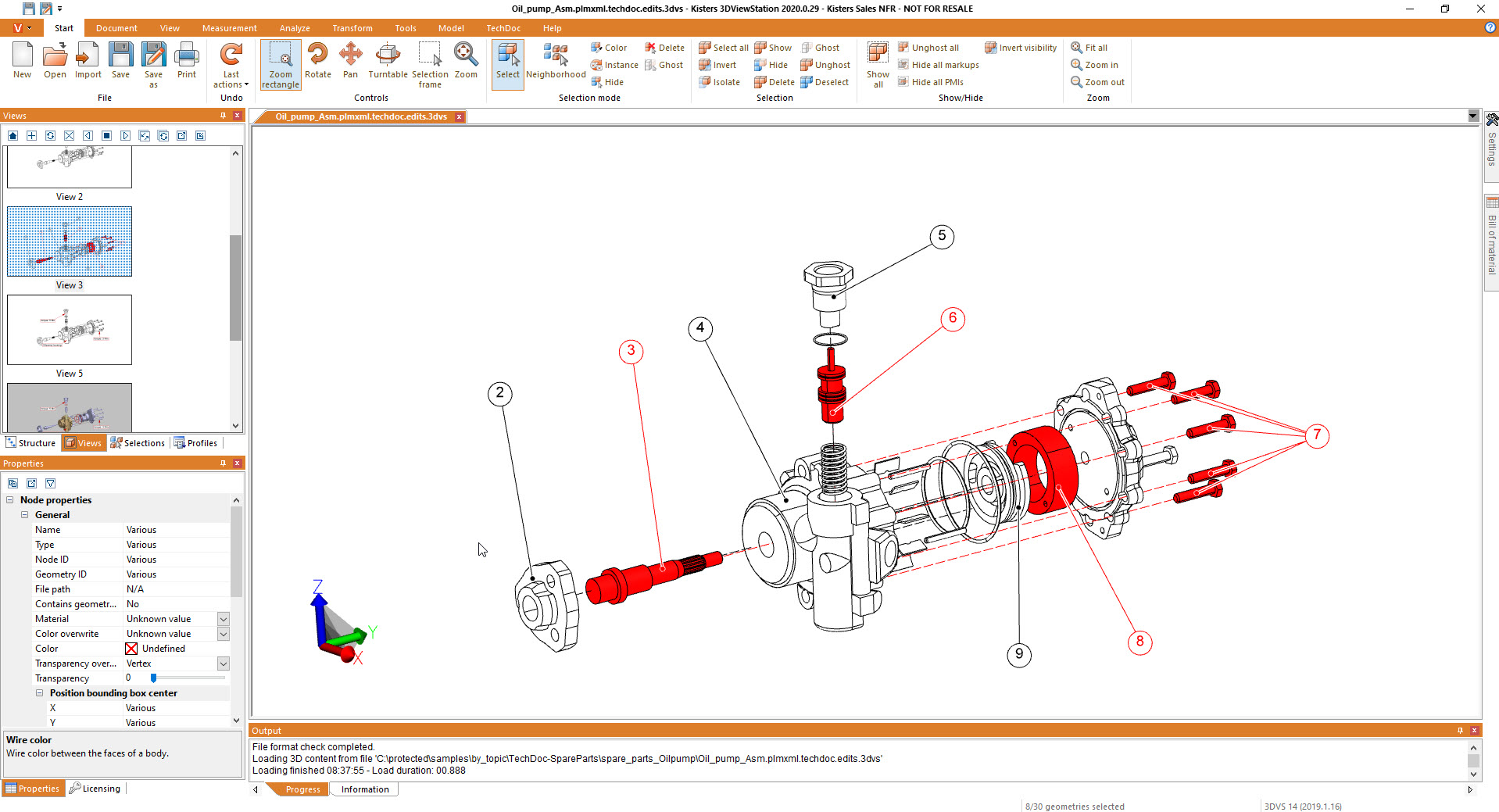

Authoring functions

- Redline / Markup

- Technical documentation incl. ballooning

- Publish

- IP-protection

- color coding

- and many more...

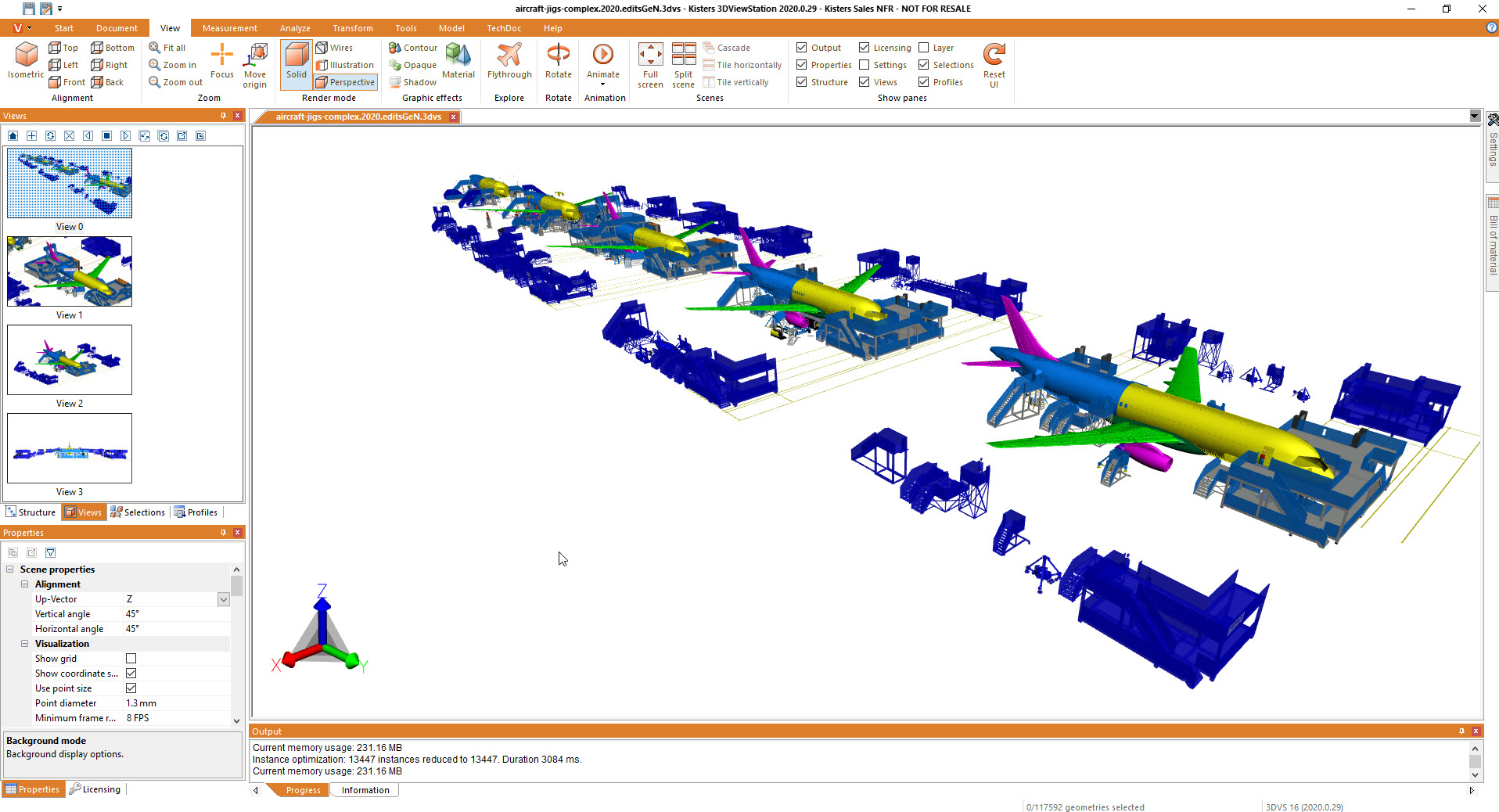

The following project examples are from our 3DViewStation Desktop viewer customers

Desktop viewer at suppliers in manufacturing industry

After a thorough selection process, a manufacturer of aerospace components replaced several existing viewers with the 3DViewStation Desktop version.

An automotive supplier for glass and elevating roofs carried out a requirements analysis and, after internet research, put three viewer manufacturers on the shortlist. Two of the manufacturers carried out training sessions lasting for days with a lot of personnel. The customer finally opted for the Kisters 3DViewStation Desktop viewer: After only two hours of product demonstration, the key users were able to do their job with their own data.

An automotive supplier for lighting systems has carried out a requirements analysis with five viewer manufacturers in the final selection. The Kisters 3DViewStation Desktop version clearly led in all categories. An important selection criterion was not met at the beginning - but was developed by the Kisters team at short notice and delivered on time.

A machinery supplier uses 3DViewStation Desktop PMI capabilities in order to support their MDB initiative. They replaced a combined 3D-PDF and JT process by standardizing on 3DViewStation Desktop viewer.

Desktop viewer at OEMs in automotive, aerospace, machinery and plant

A helicopter manufacturer uses the 3DViewStation Desktop viewer with his PLM system. Complex assemblies with up to 2-3 million parts are loaded extremely quickly and then filtered according to e.g. ECAD, standard parts or colors. Using proximity or distance search, parts are isolated within the search area or, for example, along a pipe system and transferred to a CAD system for processing using a plug-in. In addition they use the technical documentation authoring functions of 3DViewStation Desktop version to create and maintain content for their work instructions.

A well-known sports car manufacturer uses the 3DViewStation Desktop viewer to load and analyze complete vehicles with more than 100,000 parts - or just single components - via the PLM system. This also works purely file-based, i.e. completely PLM-independent.

A truck vendor uses 3DViewStation intellectual property (IP) protection capabilities in order to remove invisible parts and to alienate sensitive parts - preventing production of illegally copied parts.

and more Desktop viewer at:

A plant manufacturer uses 3DViewStation Desktop viewer to load complete plants from within a PLM system. The typical interactive functionalities are used to analyze the layouts and 3DViewStation APIs are used to add and modify components

A train manufacturer leverages 3DViewStation Desktop version technical documentation features in order to prepare data for their spare parts catalog.

A large machine manufacturer replaced Acrobat 3D and JT2Go by 3DViewStation Desktop viewer in order to re-use and author 3D annotated models, replacing the former 2D based workflow.

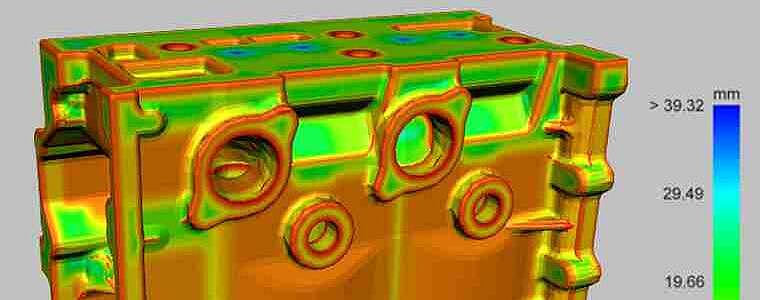

Desktop viewer at tool makers, mold & die makers, casting companies

Our model, mold & die makers use the 3DViewStation Desktop version to create quotes. All incoming data in native or neutral CAD formats will be loaded into the Desktop viewer first. Then the data will be analyzed, physical properties such as volumes and surfaces calculated if necessary, and some dimensions determined. They determine the complexity of the tool to be used with the aid of the draft angle analysis. And the powerful split or division function supports you in the mold design. The work is organized and saved in views. Our model and mold makers then receive the order with the attached geometry. They now use the 3D comparison function to determine whether geometric changes have occurred. Afterwards the order can be accepted and the 3DViewStation Desktop version can be used in production, on PCs or even on touch displays and tablets.

Many foundries use the 3DViewStation Desktop viewer to inspect the data, which is available in various data formats. They use our advanced analysis functions - also called Digital MockUp, DMU functions. Because draft angle analysis helps detecting undercuts at an early stage.