Visualization for Quality Assurance

Use 3DViewStation for 2D and 3D visualization in your quality assurance software.

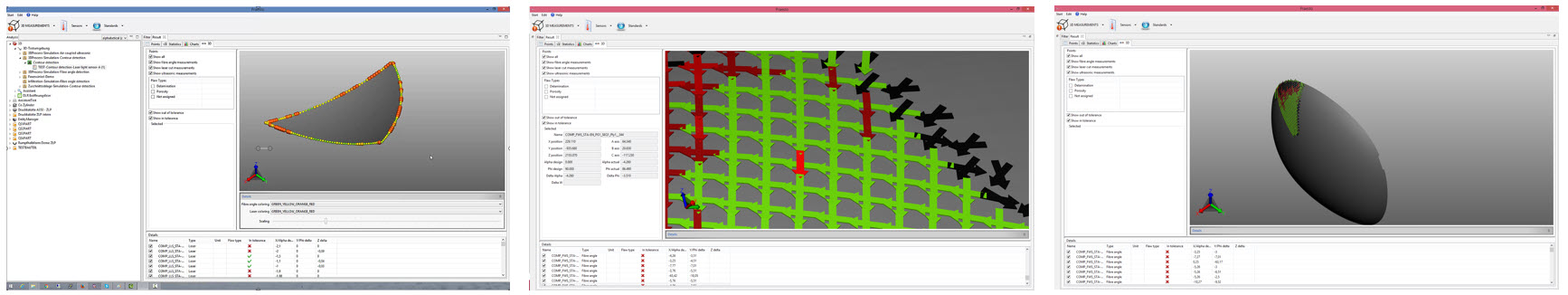

To ensure the quality of products, they must be checked before delivery to the customer. To check the products, optical methods are used, for example, which collect digital data and first store it in a database. For example, it should be checked whether the shape of a component corresponds to the specifications from the CAD model, how large the deviation is at the respective measuring points and whether the required tolerances have been met. To do this, one must first measure the manufactured component, e.g. with a 3D scanner. The subsequent target/actual comparison is much more efficient with a 3D graphic than comparing columns of data. Maybe it is a very expensive part made with fiberglass and carbon. There, the correct alignment of the fibers is critical to achieve high strength. Even a slight deviation in a range of a few degrees can result in a drastic loss in stiffness and strength. In practice, to ensure compliance with the specifications, measurements are first taken with high-precision laser scanners, among others, and then checked via 3D visualization before the components are bonded or baked.

3D viewer for higher quality

To support production, companies have developed software that not only records, manages and documents the measurement results, but also includes a 3D graphic that visualizes the measurement results directly on the CAD geometry. This is where Kisters 3DViewStation comes in. So instead of sorting and analyzing lists of measured values, you can very quickly get a visual impression and evaluate the result much easier and faster. To display the measured values on the 3D model, you can on the one hand position and align points and different 3D symbols in space via the programming interface. You can also change the size and color of the symbols to highlight results or deviations even more clearly. The industry is working with solutions that offer integrated visualization, which can be used both in the application itself and in reports.

New: Linking measured values with 3D model

Through newsletters and events, Kisters has early contact with relevant institutions of research, as a service to CAQ / QA / QS specialized development work for technical companies. In the meantime we can look back on many projects where we could help to extend the topic of image processing to 3D with our technologies. What mostly started as a download and was initially managed through our support or consulting, soon became a management issue, both nationally and internationally. The starting point was the potential automation of services that we demonstrated could occur based on certain data reported by sensors on a machine. See also our separate page on 3D graphics for HMI (human-machine interface). The fact that digital data can be linked to 3D models via a 3D viewer system means that a significant efficiency gain is achieved. The evaluation of a manufactured product is important for manufacturing companies, no matter if it is a small GmbH or a big AG, and it becomes much faster and better at the same time.

Visualize not only 3D graphics, but also 2D documents

Today, Kisters 3DViewStation is often considered the best-in-class 3D viewer solution. However, it also supports 2D with the common document formats PDF, DOCX, XLSX, etc., as well as drawings, which can be DWG, DXL, PDF, HPGL, among others. This is an advantage for QA applications, as only one viewer needs to be integrated and not, if necessary, a different product for each data format, which may not even be integrable. Thanks to a powerful API (programming interface), not only can 3D CAD data be displayed with just a few lines of code, but it can also be enriched so that the inspection results overlay the geometry. All objects are clickable and any action can be performed after clicking. Thus, a click on the original 3D model can display information about the CAD file, a click on the 3D scan model can display the associated metadata or other information. A click on an inspection point, which could also be a sphere / sphere, a colored arrow or other symbol could highlight the row in the table of measurement results. But the opposite way works as well: a click on a row with a measurement value highlighs a symbol or a point on the geometry.

Integration for desktop and web made easy

A 3D graphic component for an application in quality assurance can be the desktop version when using our 3DViewStation, our classic fat client, which is controlled via an ActiveX control. After local installation, 3DViewStation runs either embedded within the leading application or alternatively as a stand-alone application with its own user interface. You can also experience the results immersively using our 3DViewStation VR edition. This can also be controlled via an API. However, many recent applications are web-based and run in the browser, without JAVA and other locally installed components. In this case the 3DViewStation WebViewer version is a HTML 5 viewer that does not require any client-side installation. User settings are stored in a cookie on the end device. The viewer is controlled via the backend of the WebViewer server.

No 3DViewStation forum, but newsletter

Despite more than 3000 companies using our 3DViewStation as viewer, there is no forum until today. But if you are interested in our newsletter to stay up to date on 3D CAD graphics, please read our privacy policy, including the use of cookies. Through this newsletter we do not only inform you about news, we also provide an overview about the latest version of our product family and our vision. If you have been inspired by the quality of our products and would like to contribute your energy to our 3D Solution and continue your career as part of the visualization team, please check our job offers here and on the Kisters main page.

We would be happy to advise you

Sales Germany

+49 2408 9385 517

Sales USA

+1 916 723 1441

Advantages...

... for users

- Very fast and clear visual impression

- Spatial representation of the results

- Further use of the original geometry possible

- Can be used on any device and also mobile (with Web application)

- Simple operation

... for developers

- Rapid implementation of an integration

- Few lines of programming code required, as no SDK

- Same integration for application and report

- Working with own 3D symbols possible

- Only minor adjustments necessary when switching between desktop and web / mobile integrations

- Competent consulting team helps with all integration questions

... for decision makers

- Supplementary 3D graphics for QA results is a competitive advantage

- Largely CAD independent solution

- Low maintenance effort as only one product / one integration for application and reports

- No training necessary

- Cost control: Even the simplest end devices can be used (for Web applications)

- Cost control: Concurrent licensing models available