MBD / PMI Visualization

Drawingless processes made easy

- Kisters 3DViewStation helps you with your MBD (model based definition) initiative: replace 2D drawings by 3D models (3D Master concept, MBE: Model Based Enterprise)

- Re-use your CAD data with all your processes

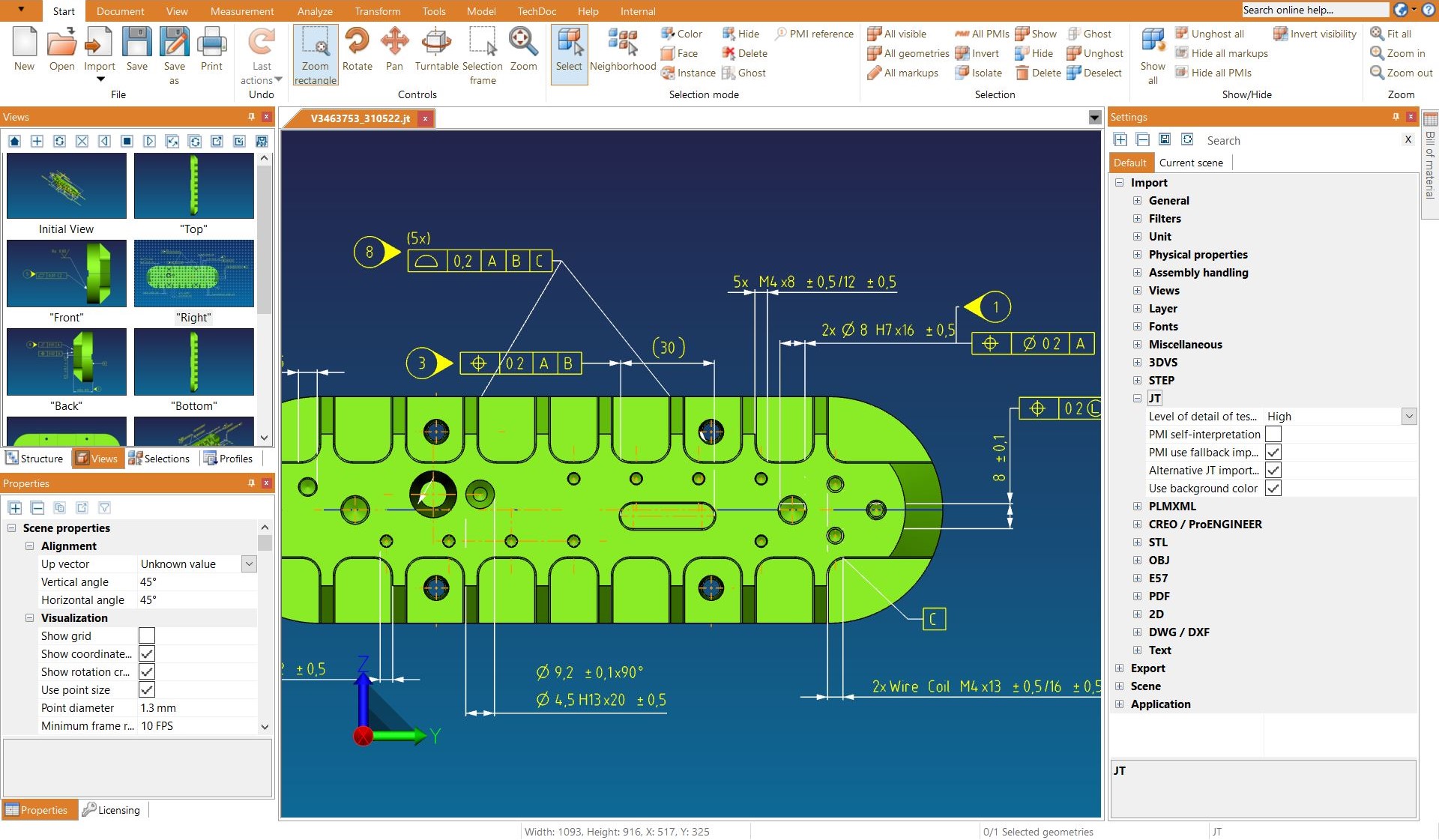

- PMI (Product Manufacturing Information) support for Catia, NX, Creo, JT, STEP...

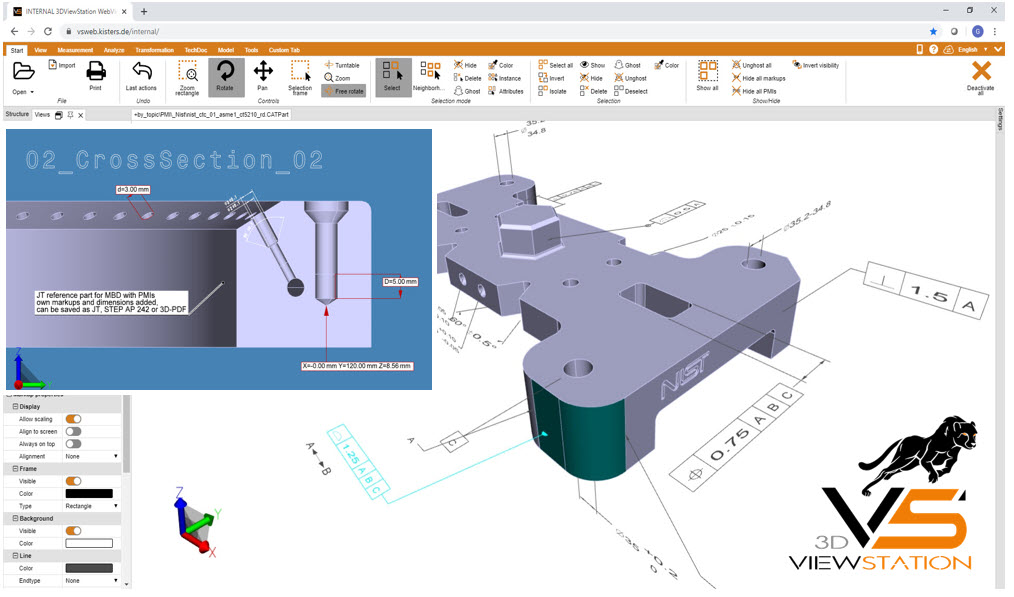

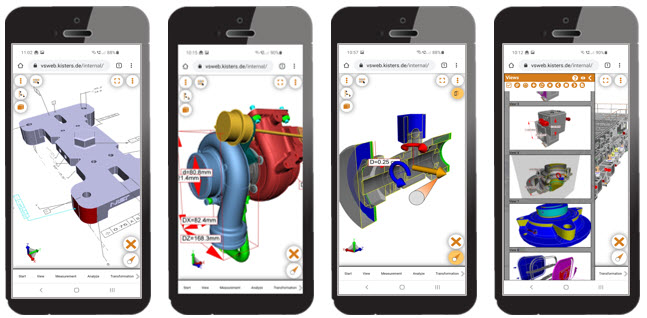

- 3DViewStation can be used visualizing 3D annotated CAD models on Desktop PCs, Office Notebooks, Tablet-PCs, SmartPhones and in VR environments

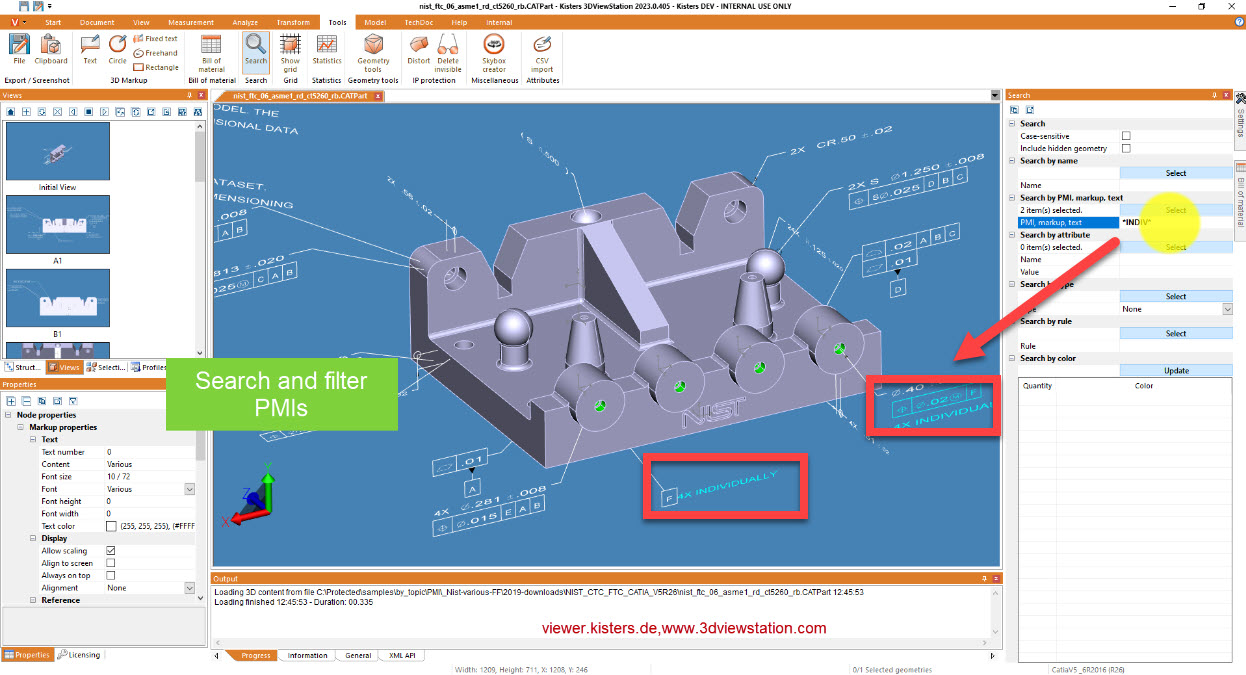

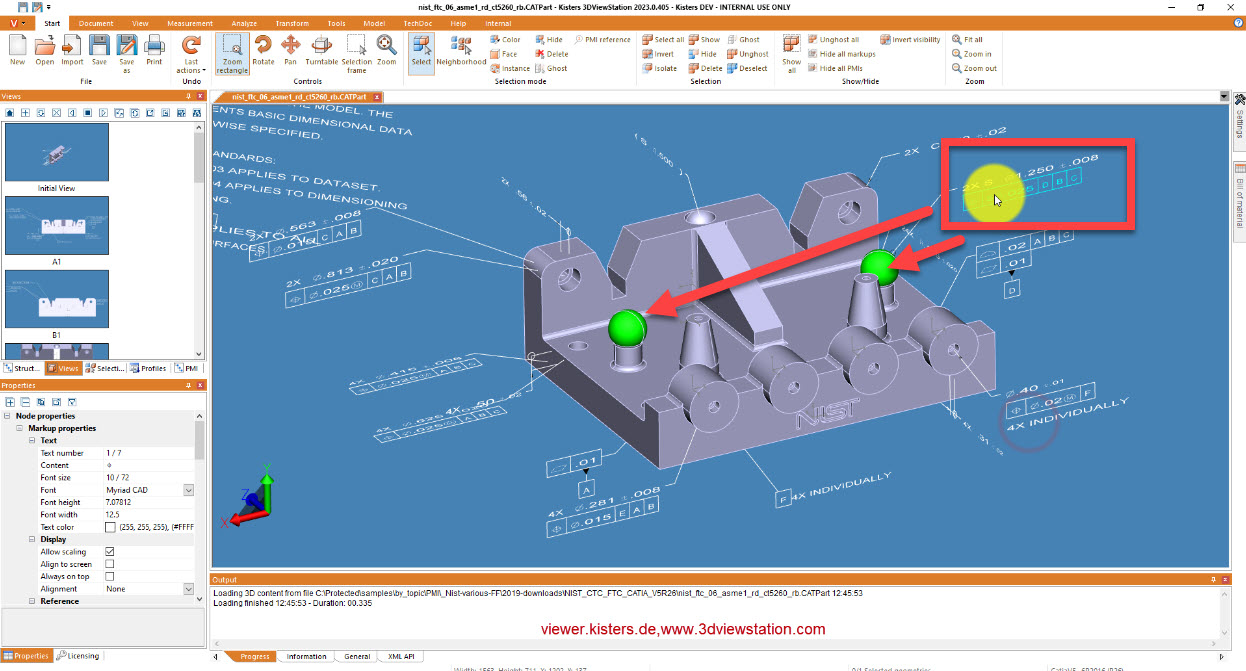

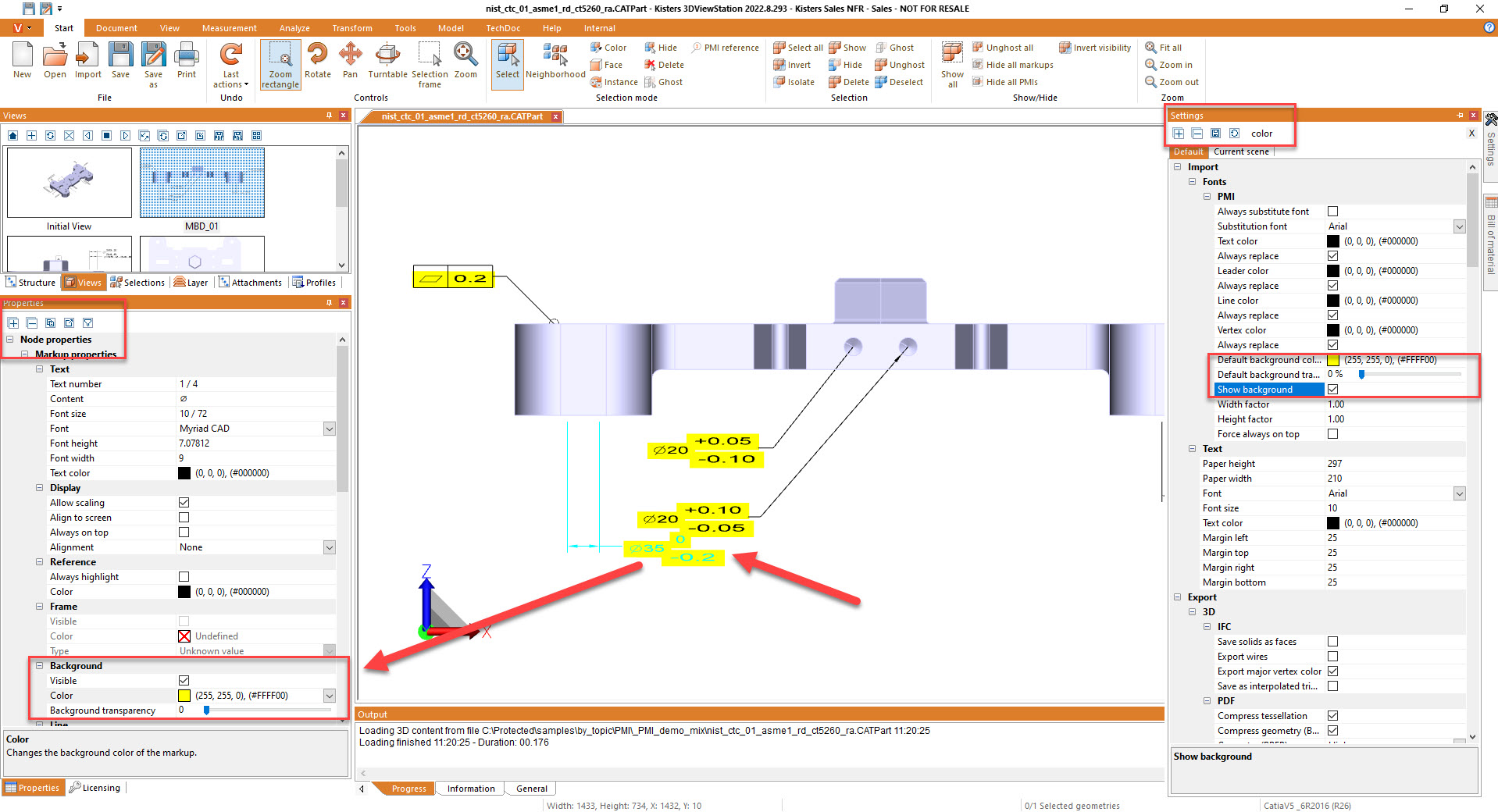

- 3DViewStation allows to view existing PMIs / PMI views / pre-defined annotations, sections and more

- 3DViewStation allows to create own markups and views, transform them into PMIs,and save them as JT or STEP AP242 file.

- 3DViewStation offers 180+ features & functions for more than just viewing. measurements, sections and compare, volume calculation, change of color and transparency.

PMIs and MBD belong together

PMI (Product and Manufacturing Information) and MBD (Model-Based Definition, means drawingless design) are two closely related concepts in modern manufacturing. Both aim to optimize the product development process and improve quality and efficiency in manufacturing.

PMI refers to the information required to describe and document a product in order to manufacture and inspect it. This includes geometric tolerances, surface finish, material specifications, manufacturing instructions and more. This information is typically represented in 2D drawings or other documents that are provided to manufacturing. However, manually creating these documents is time consuming, error prone and can lead to misinterpretation.

In a Model Based Enterprise the 3D CAD model of the product is the single source of truth. In other words, the digital model contains all the information needed to manufacture and verify the product, including PMI data. Using MBD can replace traditional 2D drawings and documents, saving time and money and reducing the potential for errors.

PMI and MBD are closely linked, as PMI data is an important component of MBD. PMI data can be integrated directly into the 3D CAD model to create a digital model that serves as the basis for manufacturing. This can significantly improve product development and manufacturing processes.

As a real world example, watch the video at the top right and see, how ASML recommends to use 3DViewStation in order to work the MBD way.

The benefits of PMI and MBD include:

- increased Efficiency: using PMI and MBD can simplify and automate multiple steps in manufacturing, saving time and money.

- redcued Errors: PMIs reduce the potential for errors and misunderstandings because all relevant information is contained directly in the 3D CAD model.

- more flexibility: MBD provides more flexibility and agility in product development and manufacturing because changes to the 3D CAD model can be made quickly and easily.

- better Collaboration: PMIs enable better collaboration between different departments and stakeholders in manufacturing, as everyone can access the same data.

- improved Quality: MBD helps improving the quality of manufactured products, as all relevant information is contained directly in the 3D CAD model, ensuring greater accuracy and precision.

3D annotated models increasingly replace 2D drawings

For centuries, two-dimensional drawings were the standard when it came to describing technical products, manufacturing processes or even service or repair procedures. A drawing consists of various important components: For example, the drawing frame contains metadata such as the drawing number, the version, the last modification date and the release date, among others. The drawing itself can contain an overview as an ISO view and usually some section or detail views with dimensions and information on surface quality and tolerances.

With the proliferation of 3D CAD, there has been a long struggle over how to handle manufacturing information. For a long time, 3D models were used only in the acute design phase, and 2D drawings were subsequently derived from the 3D models for manufacturing purposes. A laborious, slow and costly process against a background of frequent changes.

Avoid drawings

Many companies today try to avoid the effort of creating 2D drawings and thus relieve the engineering department. Instead, the information that makes up a drawing is attached directly to the 3D model. So-called PMIs, product manufacturing information. What used to be detail and section views are now PMI views, which a good viewer like Kisters 3DViewStation shows as a list of thumbnails, and which can still be dumped or printed to a 2D PDF if needed. Metadata of the former legend are now so-called billboards, i.e. text blocks standing in space. Surface qualities and tolerances are linked to geometric objects and are usually also represented as attributes. Prepared in this way, 3D models can also be easily used in manufacturing, for example on touchscreens or tablet PCs.

Product and Manufacturing Information (PMIs) can therefore offer many advantages in Model-Based Definition (MBD) initiatives:

- Using PMIs can speed up processes from design to manufacturing by eliminating the need to manually create engineering drawings and other documentation, saving time and money.

- By using PMIs can minimize errors and misunderstandings that occur when information is manually transferred from design to manufacturing.

- PMIs enable a uniform, consistent and accurate representation of product and manufacturing information that can be used by all stakeholders in the value chain.

- PMIs can help improve data management by reducing the manual creation of documentation, thereby optimizing data exchange between different departments and systems.

- And PMIs provide a way to integrate QA information into the 3D models to ensure that the product meets the required quality standards throughout the production process.

Does the use of viewers make sense with MBD?

Yes, the straight use of viewers makes sense at MBD and offers several advantages.

A viewer such as Kisters 3DViewStation is a software solution that allows 3D models and PMI data to be easily viewed and analyzed without the need for specialized CAD or CAM software. Here are some of the benefits of using CAD viewers at MBD:

- Using 3D CAD viewers like the Kisters 3DViewStation is often less expensive than using specialized CAD or CAM software. Viewers such as 3DViewStation cannot model, but still offer much more functionality known from CAD systems than is usually expected.

- CAD viewers are often more user-friendly than dedicated CAD or CAM software and require less training and familiarization. In particular, MS Office-like user interfaces make the software easier to use. Many 3DViewStation customers will confirm.

- 3D CAD viewers allow different departments and stakeholders in the value chain to access and analyze the same 3D models and PMI data, facilitating collaboration and communication. This collaboration can be done in real-time using web-based solutions such as the 3DViewStation WebViewer version, or asynchronously using the Kisters 3DViewStation Desktop version. There are also online collaboration solutions such as Kisters VisShare for these purposes.

- Viewers can also be used for quality control and inspection of manufactured parts to ensure that they meet the given specifications. Additional benefits come from integration with specific QA applications, where, for example, via API, QA results can be overlaid with the original CAD file or results can be colored according to importance.

- Viewers often offer more flexibility and mobility than dedicated CAD or CAM software, as they can be accessed from different devices and platforms. Here, for example, the Kisters 3DViewStation WebViewer version should be mentioned.

Secure archiving

Archiving drawings has also come a long way. Today, paper archives have mostly been dissolved and digitized using scanning technology. Today, 2D drawings created by CAD are usually archived in the PDF-A data format and 3D CAD models as STEP. Since the STEP variant AP 242 also supports 3D annotations, companies are also on the safe side here.

Challenges in the transition to PMI and MBD

The transition to PMI and MBD can present several challenges for organizations. Here are some examples:

- Many organizations may not have experience with PMI and MBD and therefore need to plan for training and resources to acquire the knowledge needed to make a successful transition.

- Implementing PMI and MBD typically requires the use of specialized software tools that may not be available or support existing infrastructure.

- PMI and MBD require accurate management of 3D model and product data. It can be challenging to convert existing data to a new format and ensure that all stakeholders have access to the correct data.

- MBD requires closer collaboration between different departments within a company, including engineers, designers, manufacturing technicians and quality assurance. Coordinating these different groups can be difficult, especially if everyone is working with different tools.

- The usage of PMIs is guided by different standards and norms that can be interpreted differently by companies. It is important to ensure that everyone involved is familiar with the requirements and is implementing them correctly.

- Implementing MBD requires a change in company culture and way of working, including moving from 2D drawings to 3D models and implementing new processes for capturing product and manufacturing information.

- Implementing MBD can be costly, especially if new software tools, training and resources are required.

It is important to address these challenges early and develop a clear strategy for the transition to PMI and MBD to ensure that the transition is successful and effective.