Advanced Visualization & Digital Mock Up (DMU)

DMU - quick, easy, inexpensive

In addition to the standard functionalities, the 3DViewStation also offers many advanced tools for digital mock-up (DMU). It combines uniquely fast performance, extensive functionalities and simple, intuitive operation. This has been attested to by many customers.

What is the digital mock-up about?

At DMU, it's about no longer building physical prototypes, but rather relocating this process step into the digital world. As a result, companies try to become faster in product development and also to reduce costs.

In the past, analog prototypes of a technical product were manufactured. In the early design phase, these were often clay models. In the next step they were modeled in the CAD system. In the age of the digital thread, attempts are made to map as much information as possible in a digital product at an early stage, to carry out virtual simulations and to prepare further processes. Among other things, collision checks enable potential problems in production, assembly or ongoing operations to be identified very early on.

Different understandings of the term "digital mock up"

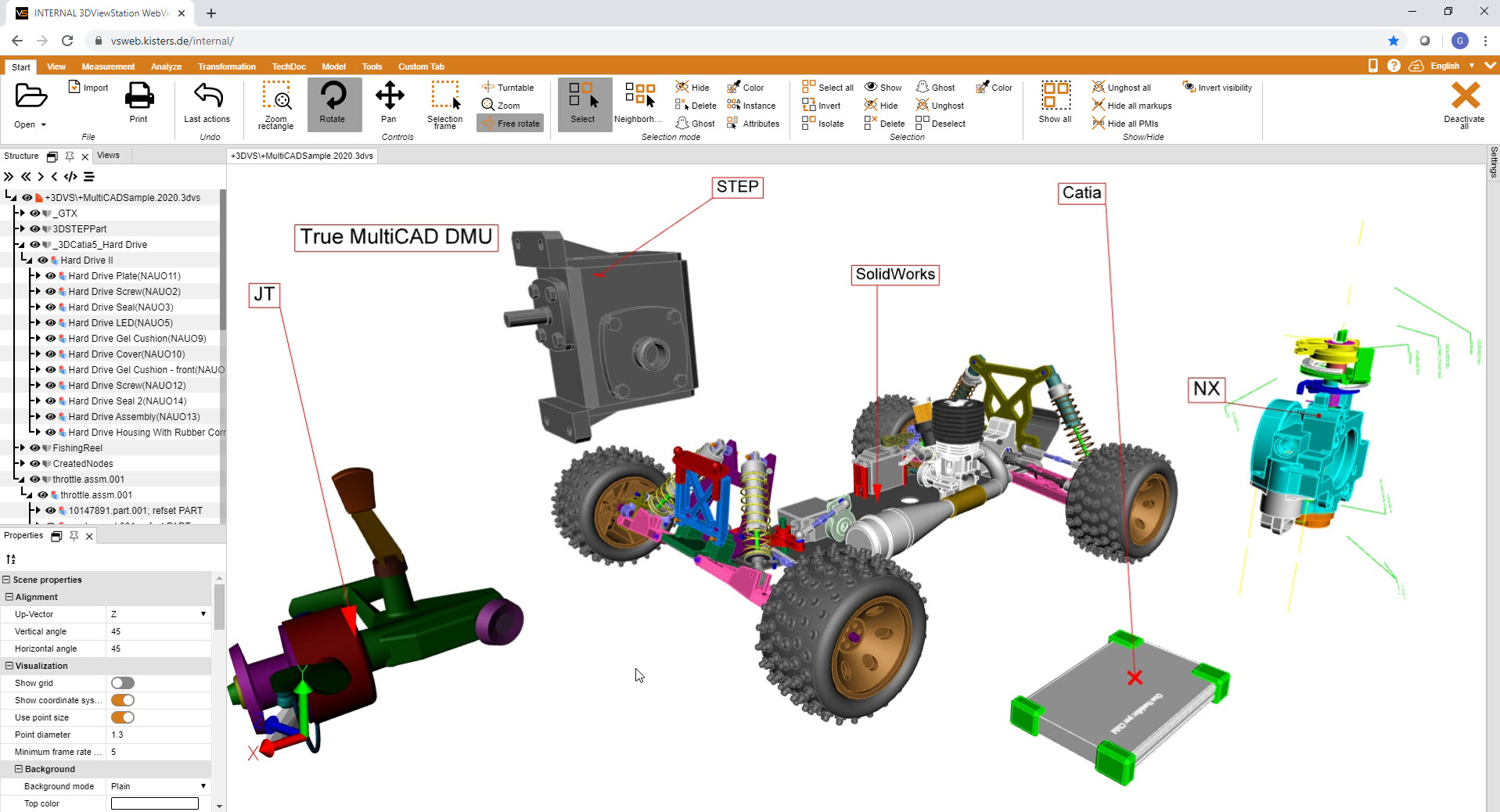

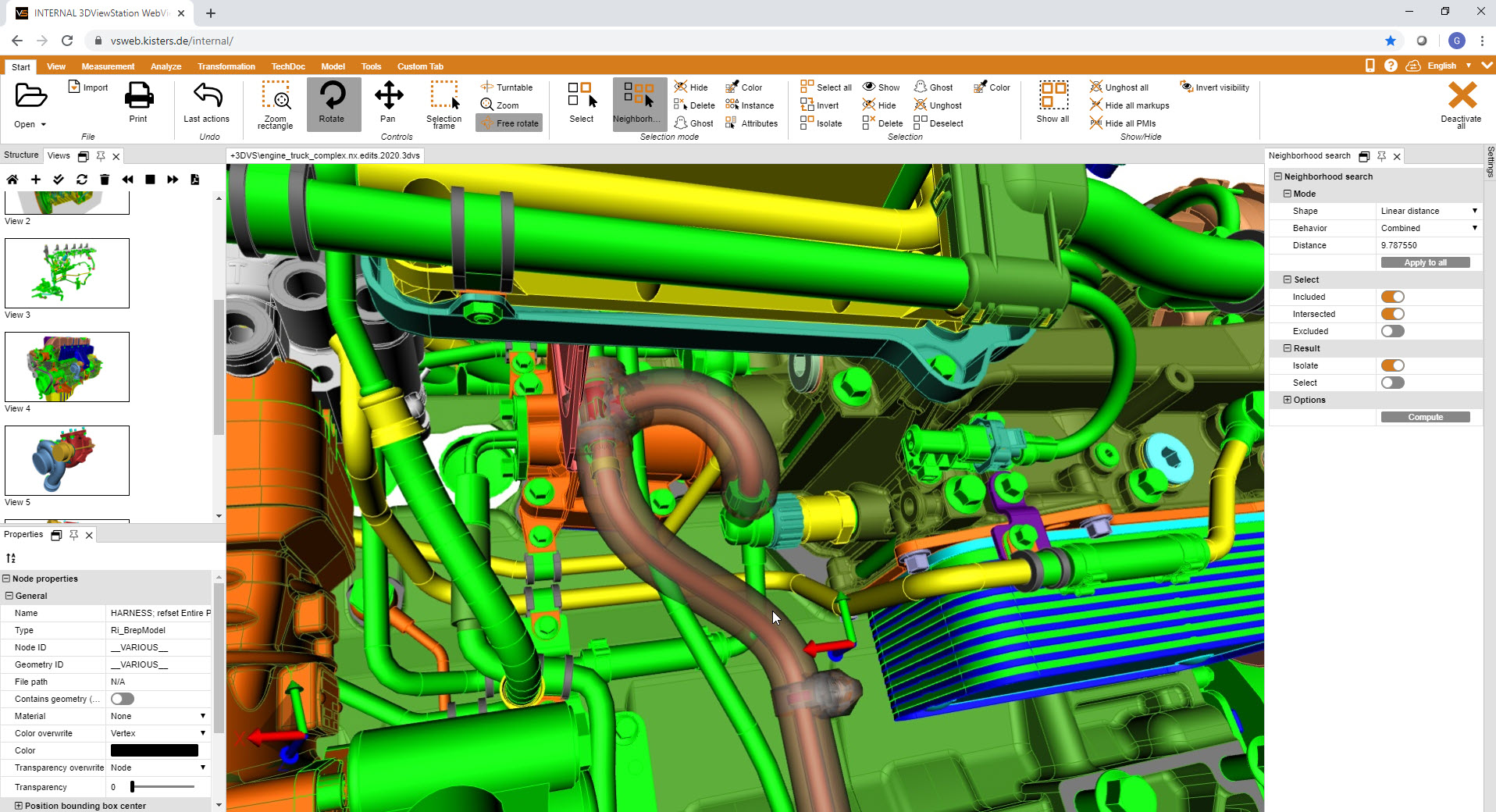

The use of the term digital mockup is very different in practice. Sometimes you get the impression that it is already possible to load a CAD model. For others, it is sufficient to load two CAD files into the same scene, be they from the same CAD system, but at the latest if they come from different systems. Others only offer translators in a single data format, e.g. JT, and then even speak of MultiCAD DMU as soon as several JT files are loaded together. Most of the time, however, DMU is more about the sophisticated functionalities that often require more complex calculations and sophisticated graphical output. So not only to load and measure two JTs together, but rather to subject a Catia and possibly an NX module to a collision investigation in a common scene.

Real multi-CAD mock-up with the 3DViewStation:

The 3DViewStation supports many CAD file formats

Create your own digital mockups (digital prototypes) by first loading a model and then importing additional CAD data from different sources into the same scene, via the import dialog, by drag & drop or automatically via API (e.g. from a PLM system out).

3DViewStation thus offers real MultiCAD DMU. No pre-conversion into a common data format is necessary. However, this is possible and sometimes advisable in order to reduce loading times. So if we only check an assembly with a few hundred parts, such as an axle, then you can work with native CAD data. However, if you are examining a complete ship with millions of components, then it is very advisable to carry out a pre-conversion.

Many digital mock-up functions are available:

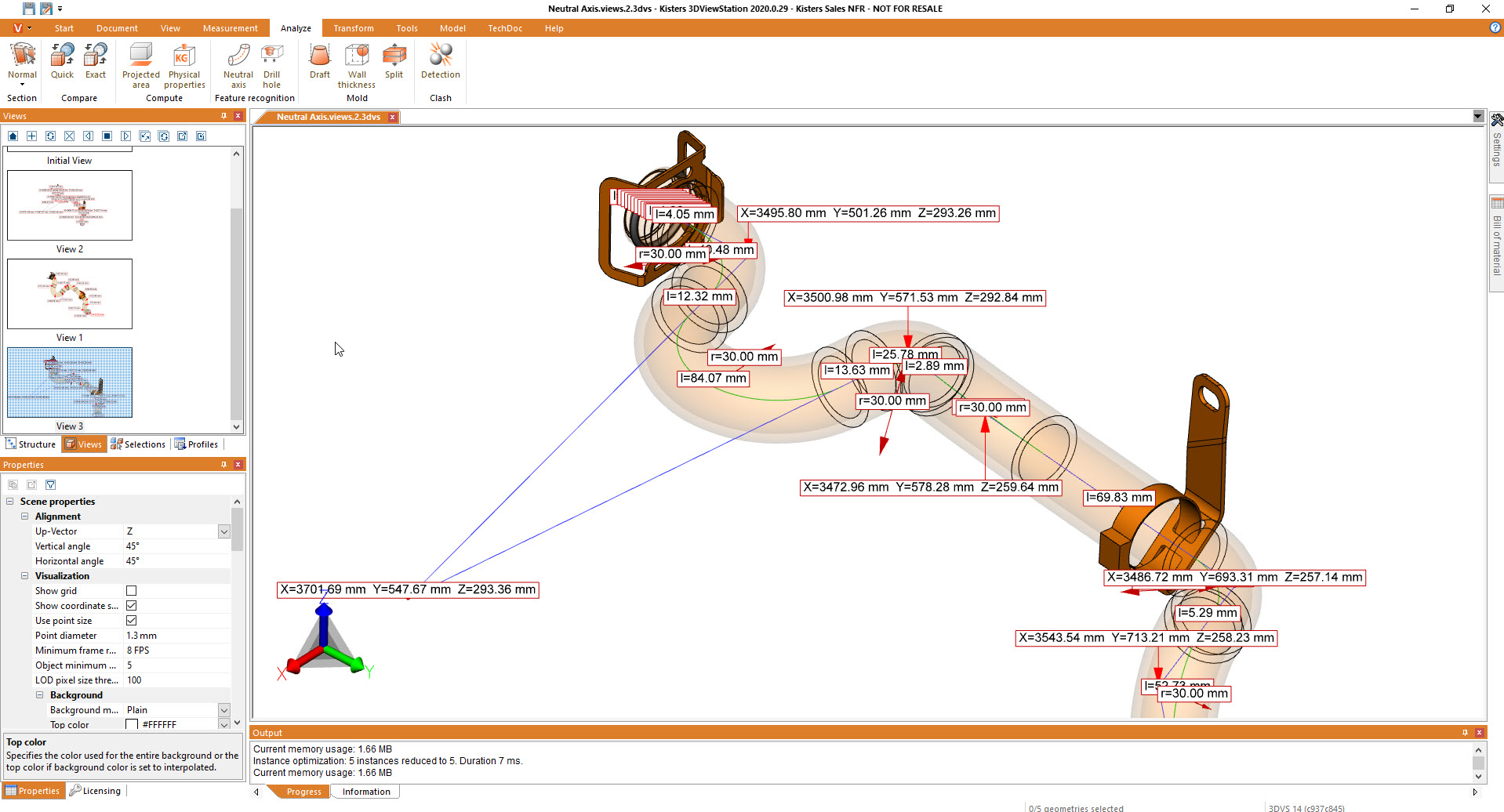

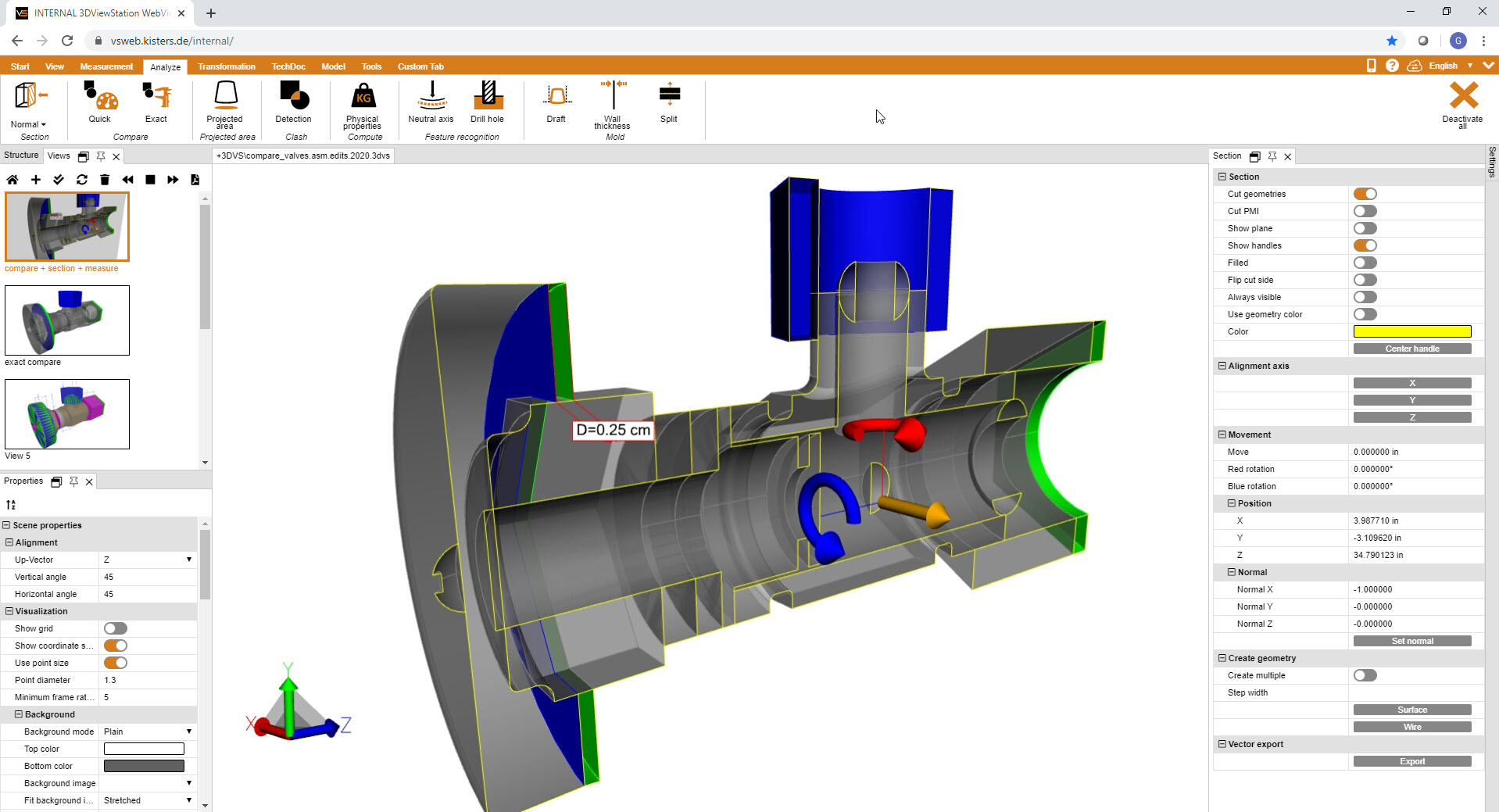

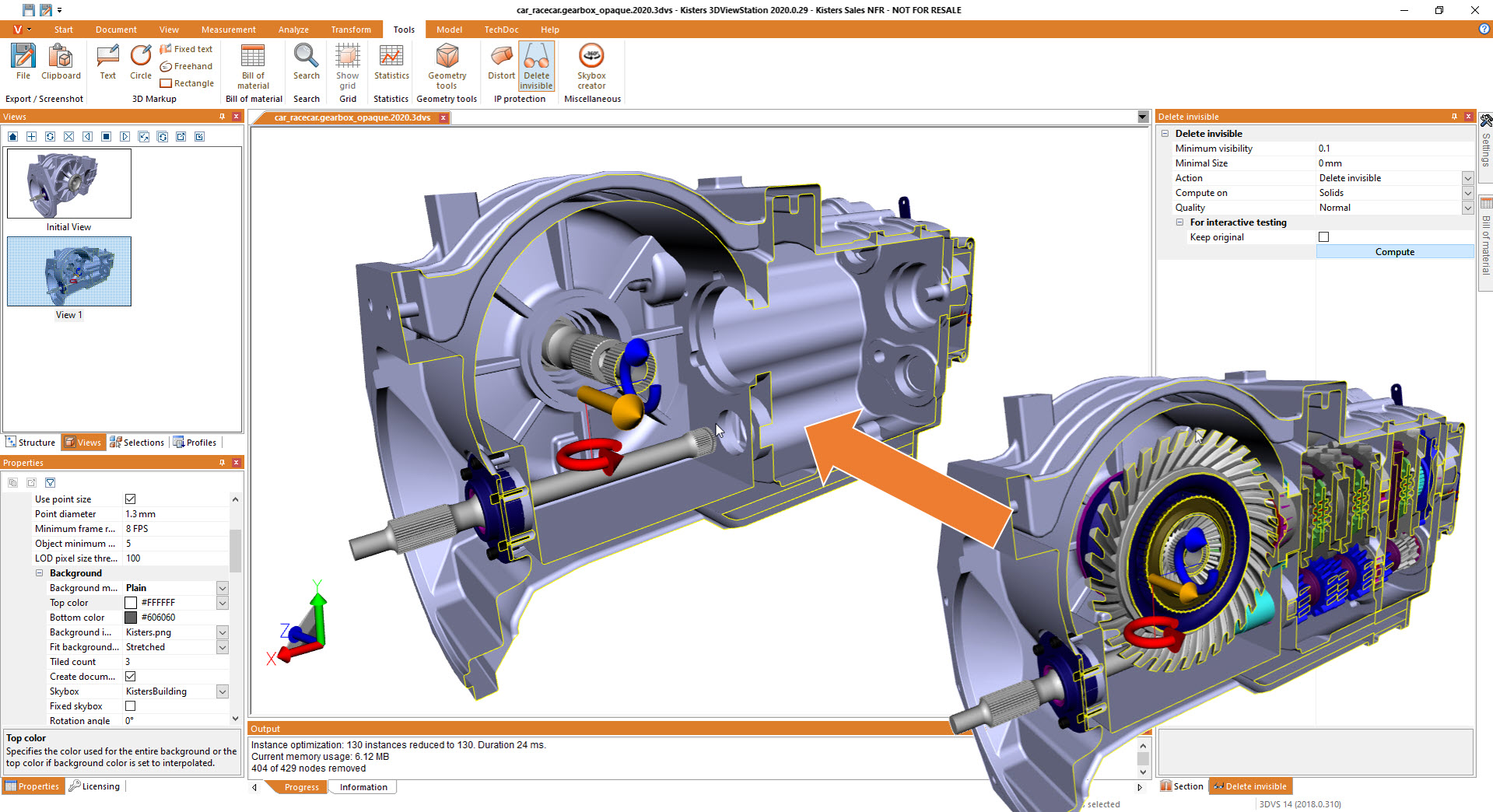

The 3DViewStation provides some advanced digital mock-up (DMU) functions, such as:

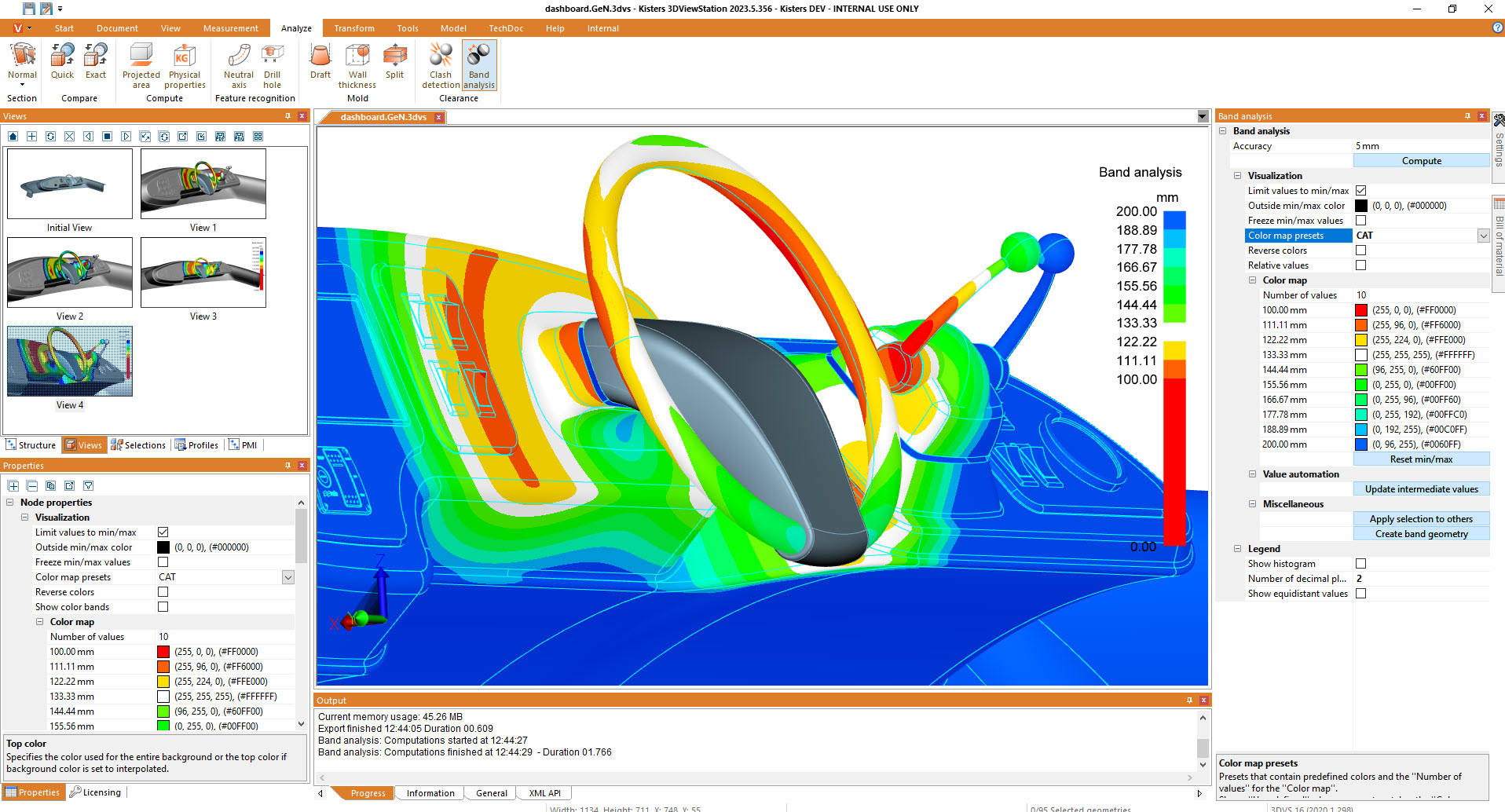

- wall thickness analysis,

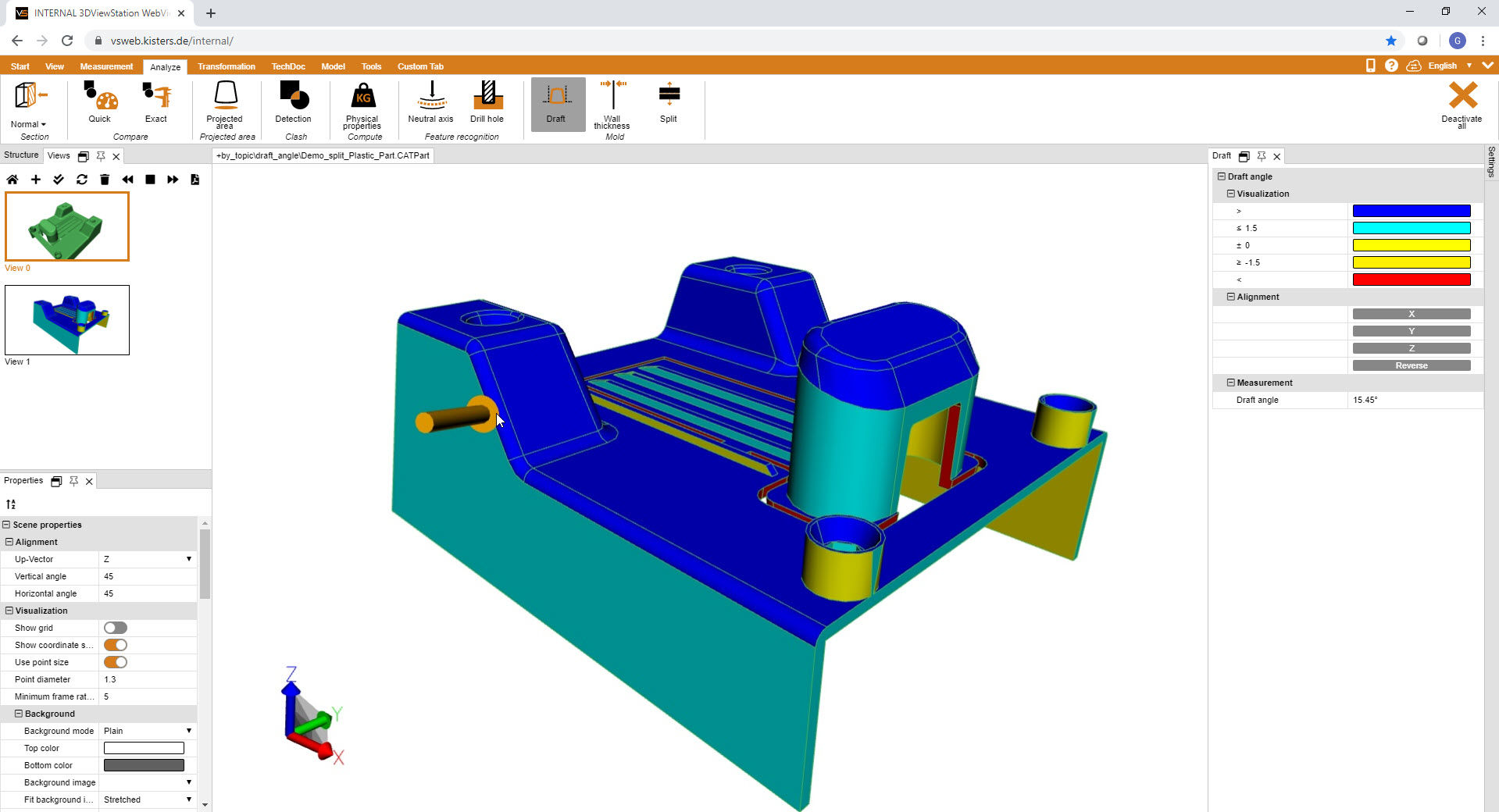

- draft angle analysis,

- Undercut Analysis

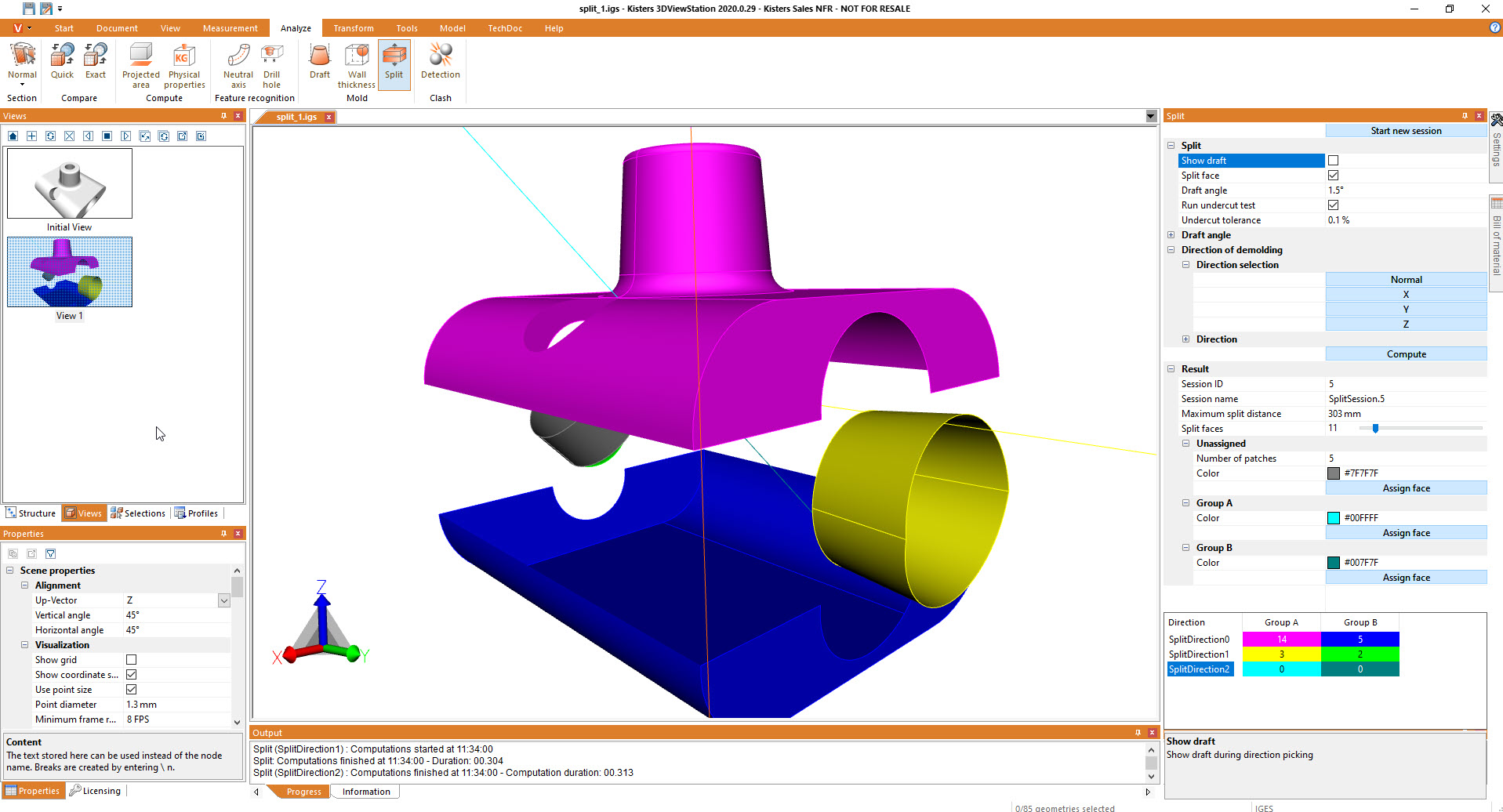

- split function,

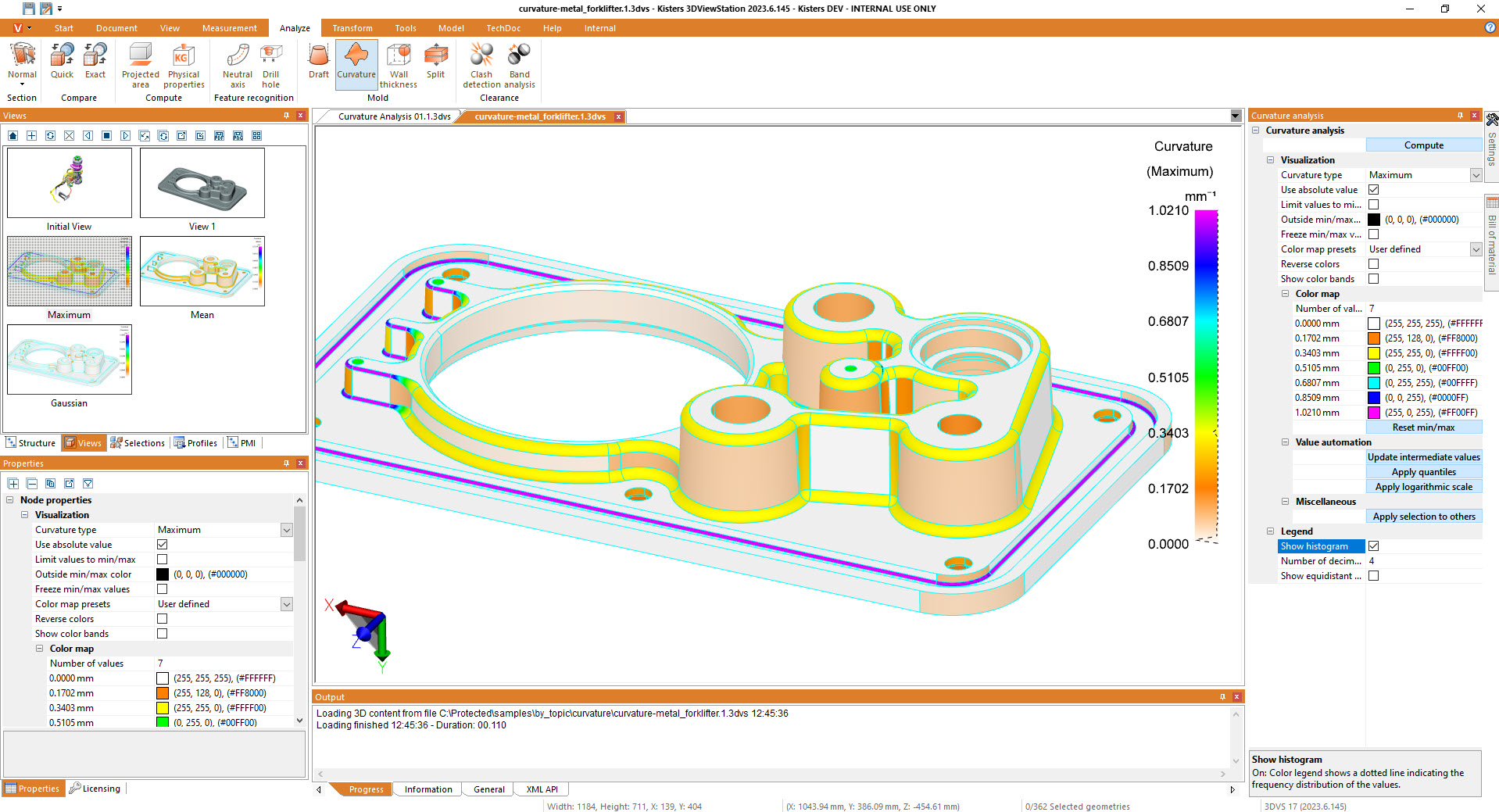

- curvature analysis,

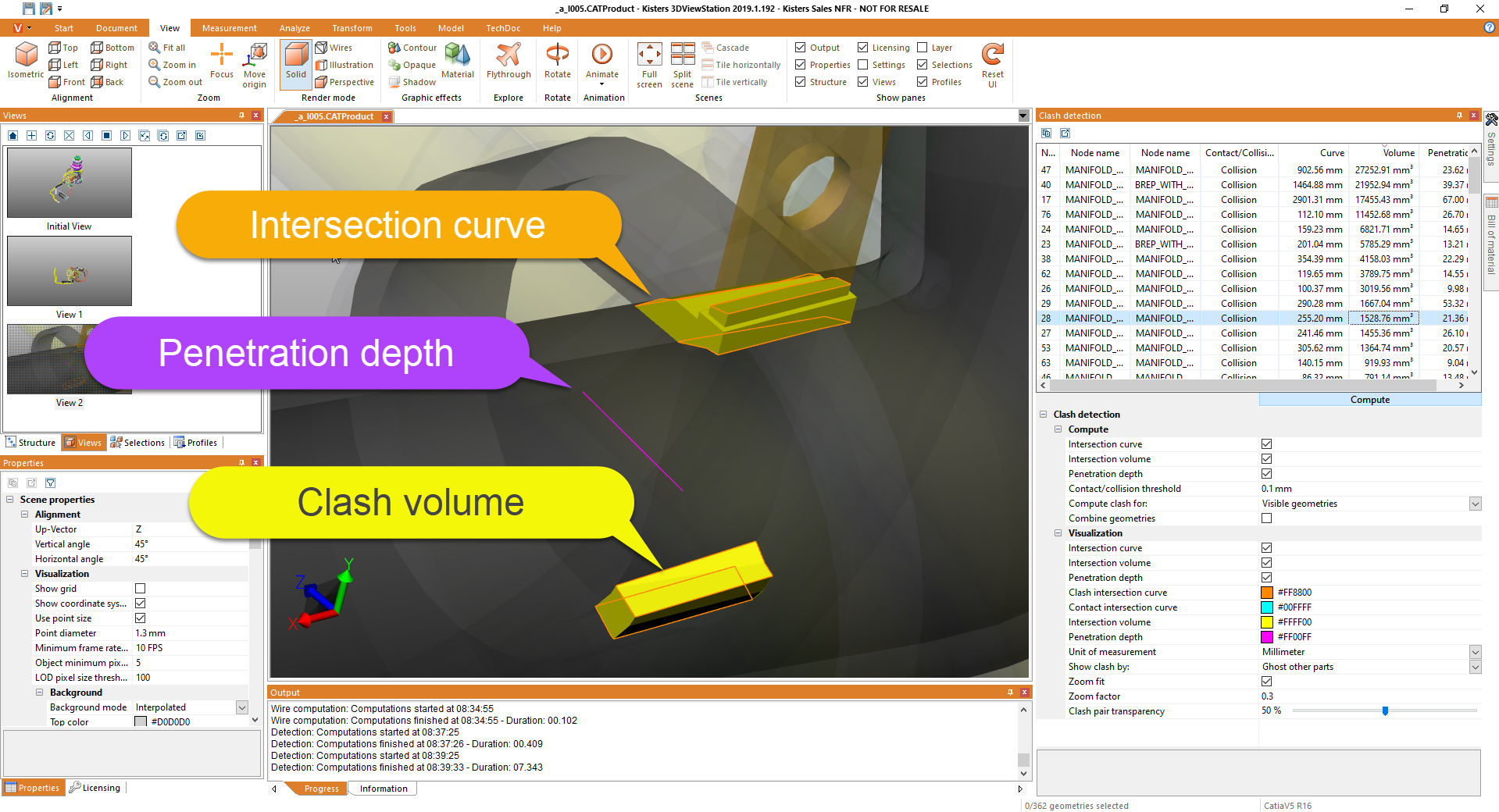

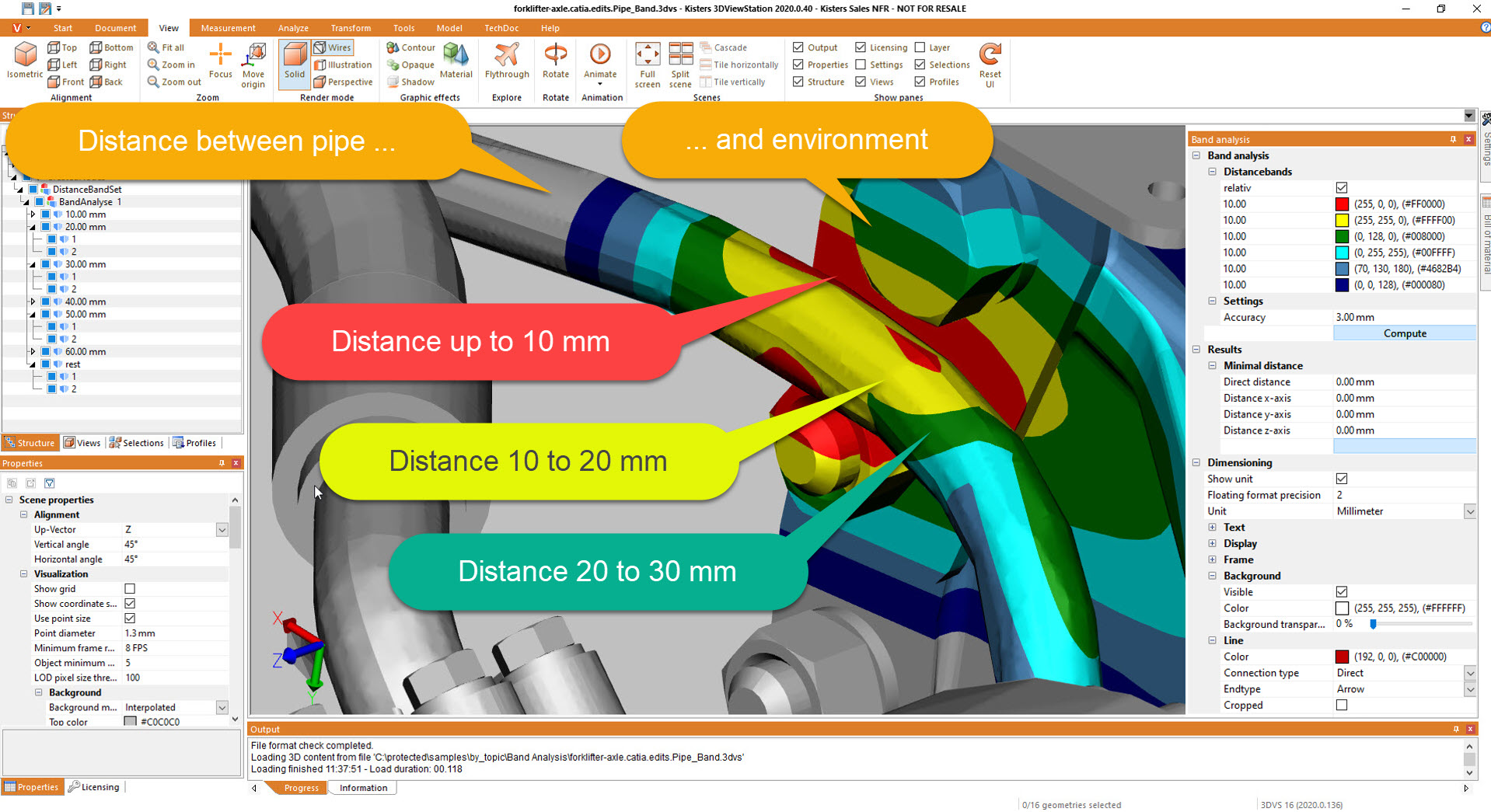

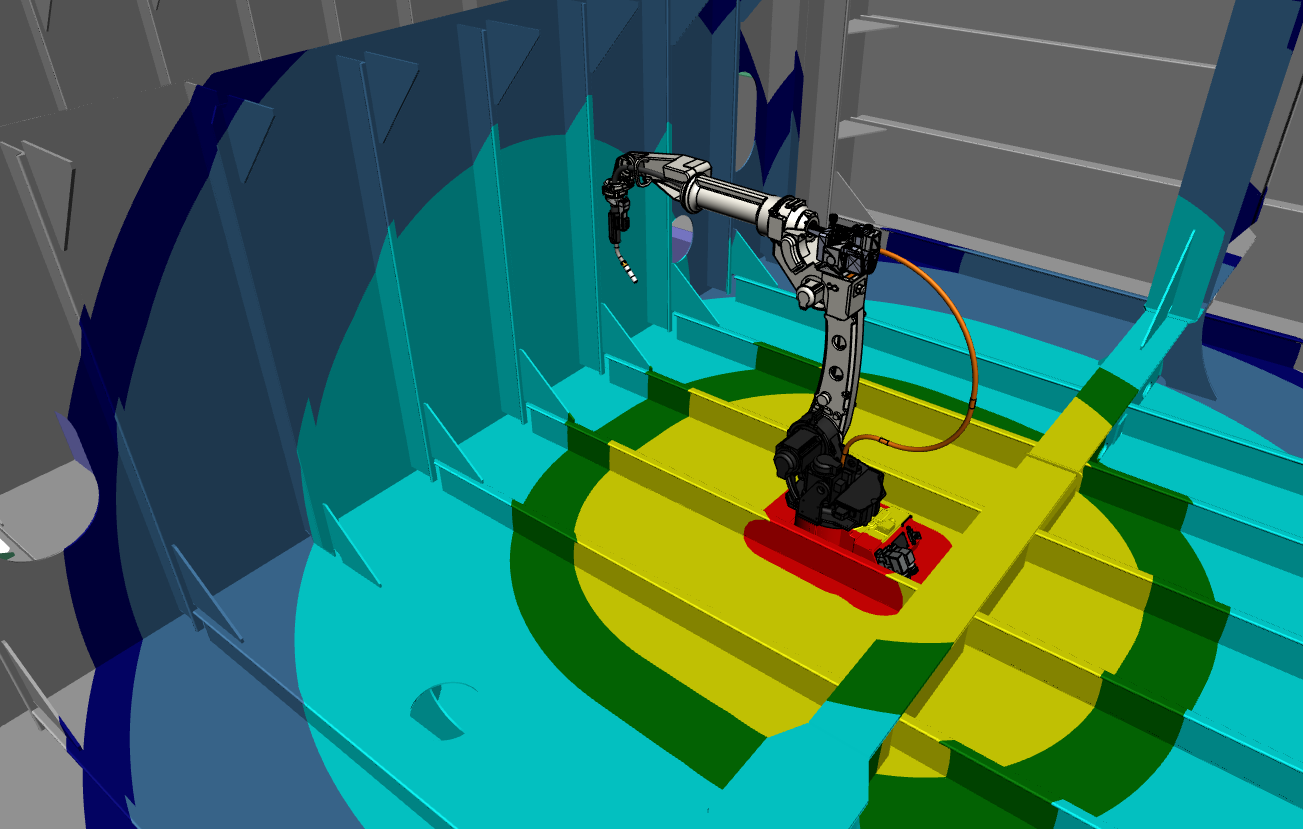

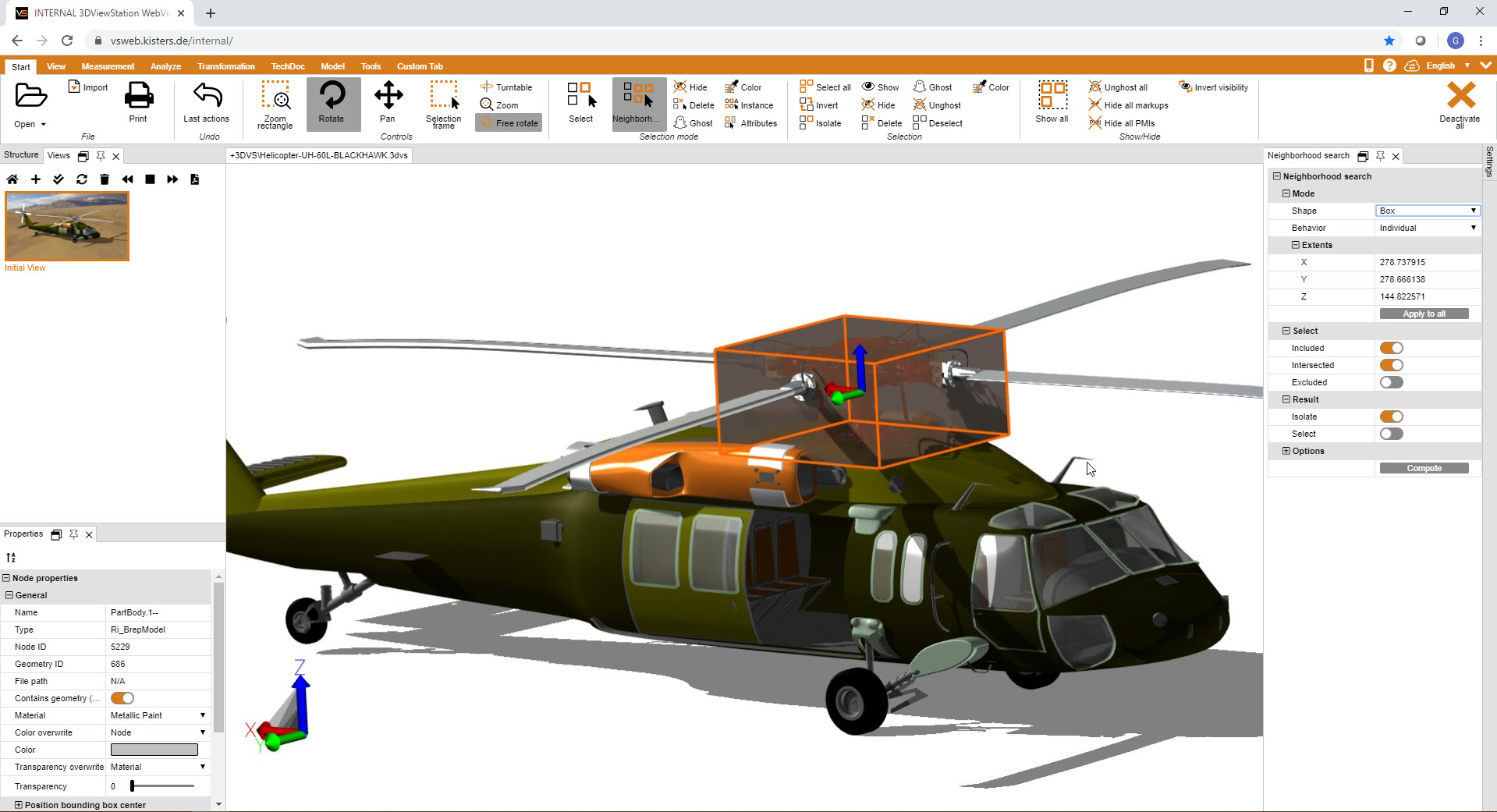

- Collision detection and distance analyzes (Clash & Clearance)

- Distance band analysis

- Generation of coordinate systems

- Move, rotate, and scale geometries

- Alignment with or without boundary conditions

- Automatic alignment of two solids: best fit

- mirroring

- automatic and manual explosion

- Extract surfaces

- Merge objects

- Feature recognition

- Calculation of the neutral fiber

- Calculation of surface, volume, projected area

- Reduction of tessellation

- Removal of small geometries

- Detection of instances

- Removal and / or recalculation of edges / surfaces / normals

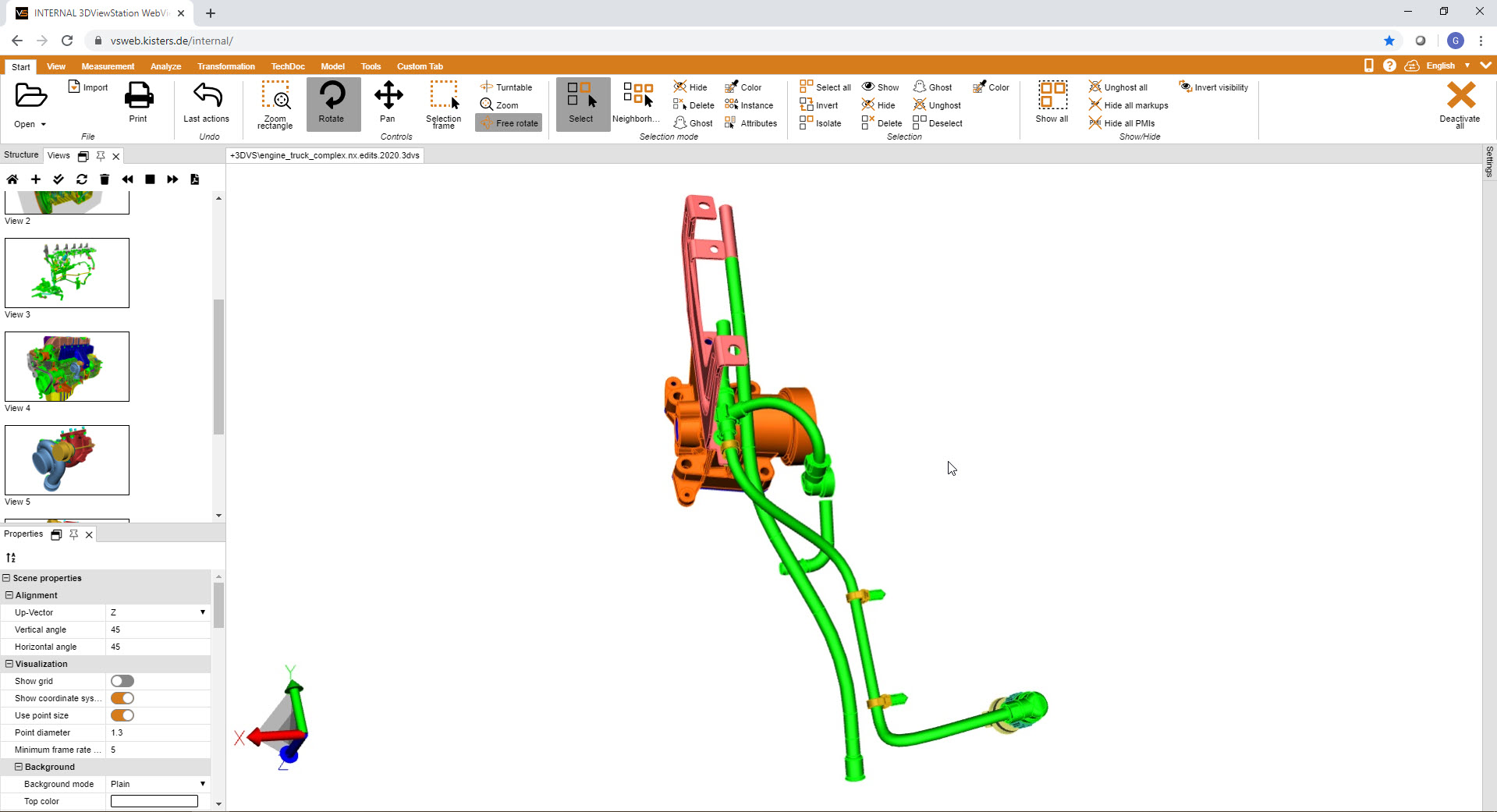

You can also use the 3DViewStation as an authoring tool to create a series of views for a meeting or - as part of work preparation - for an assembly sequence. Views show very clearly what it is about via a preview image (thumbnail). You can also rename and rearrange them or print them out. You can of course save these views, activate, change and overwrite them individually or play them back animated like a simulation. It's as easy as a 3D Powerpoint.

High End Digital Mockup for Windows, DMU2Go for Mobile

Today we find digital mockup functions predominantly in classic desktop applications on powerful PC hardware with many cores, a lot of memory and expensive graphics cards. The 3DViewStation desktop version also covers this area with its DMU functions. But it can also be used very well on notebooks, which is interesting for mobile power users.

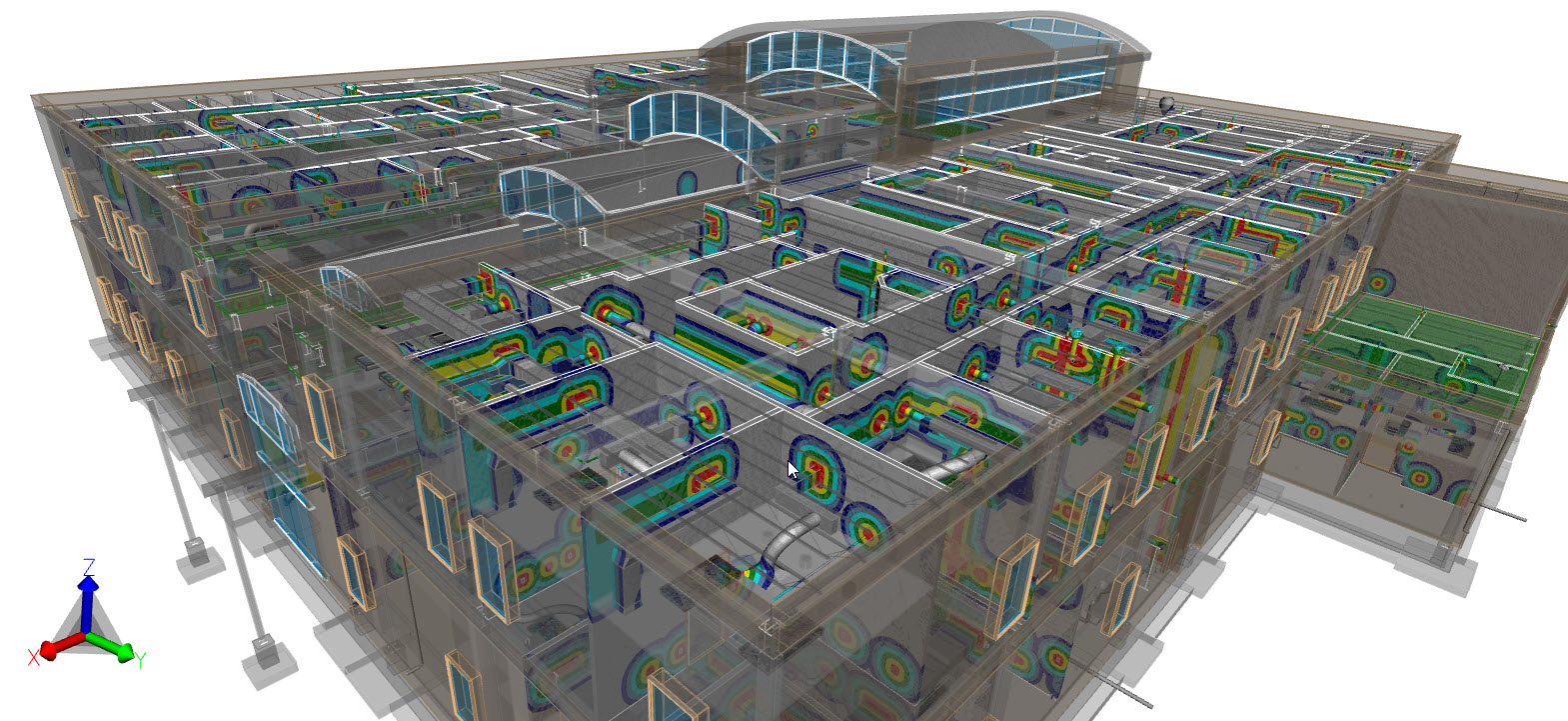

It is rather unusual that the Kisters 3DViewStation WebViewer version provides the same DMU functions in the browser. In this way, you can even carry out complex examinations independently of the end device. So both on PCs and Linux machines, tablets under Windows, Android or iOS and even on smartphones. The latter is unlikely to play a role in practice. But it is important to know that this is technically possible, so we as the manufacturer do not limit it. Since we are the only manufacturer on the market to use the same core in all product variants, we are also able to offer the same DMU functionalities in a VR environment. So if you want to carry out a wall thickness analysis in VR, for example, which clarifies the different wall thicknesses via a gradual color gradation, you are in very good hands with us.

Digital mock up also integrated

All members of the 3DViewStation product family can be used stand-alone or integrated in PLM or other leading systems. So if you are planning to run your advanced analyzes or DMU examinations connected to a PLM system, then you have come to the right place. Our API (application programming interface) is usually used in these scenarios. With their help, for example, assemblies can be loaded into the 3DViewStation, a collision investigation can be started with parameters from the outside and the results can be written back to the leading system. Since every product variant of the 3DViewStation has an API, individual steps can be carried out in the different product variants. For example, carry out the aforementioned wall thickness analysis in VR and write the result including the preview image back to the web-based PLM system. Check the results there with the WebViewer and, if necessary, initiate a change process or carry out further investigations with the desktop version.

The Kisters 3DViewStation is your digital mock up tool!

The Kisters 3DViewStation is not only your multi CAD viewer, but also your digital mock-up tool with advanced 3D analysis functions, developed for the manufacturing industry. Most users install the 3DViewStation desktop version on a local desktop PC or notebook. Alternatively, the 3DViewStation WebViewer version can be installed on a server. In this way you have an online DMU tool quickly and flexibly. No installation is now required on the device and you never have to take your data with you when you have to travel. In addition, your data is safe if you should make it available online for viewing by your business partners with whom you are in contact. All the end user needs is a modern browser - no downloads in advance for the appropriate JAVA Runtime plus JAVA 3D plus JAVA applet as for AutoVue, but also no browser plug-ins that have to be downloaded and installed first. We call this zero admin, zero install - the easiest and fastest way for demanding 3D CAD viewing and mobile DMU.

Talk to us now and test your DMU tool for free!

We are now the next logical step. Why wait now? Talk to us today and let us explain the advantages of the 3DViewStation for DMU purposes to you over the phone. Or we meet virtually via web meetings or in person at user conferences and trade fairs in Germany, Europe, the USA and Asia or at your premises. You are welcome to download a test version of the 3DViewStation Desktop for your PC. Then you can try out the Kisters 3DviewStation with your own files at your leisure. But you can also test the 3DViewStation WebViewer version at any time with your files or files provided by us - online of course. You only need to register once and, if necessary, have the upload enabled for your data.

Many more ideas for DMU customers - driven

We started out over 25 years ago as a reseller of technical 2D viewers for the manufacturing industry. At that time the important data formats were TIFF, CALS and JPEG. That was the time of the switch from paper drawings to electronic documents, the mass scanning, the dissolution of paper archives.

The first 2D CAD formats were soon added, including DWG and PDF as widely used data formats. Then the time of the 3D CAD systems began. Today Catia, Siemens NX and Creo dominate the high-end area, but SolidWorks, SolidEdge, Inventor and Co are probably even more widespread. During this time, Kisters sold specialized, pure 3D viewers, which were generally quite limited in terms of 2D support. After all the manufacturers were gradually bought up, the new owners became less and less able to meet market requirements. That is why we started our in-house development over 10 years ago and have since then been developing very closely to your needs, the customer requirements. We are interested in your requirements, your ideas for today and for tomorrow, regardless of whether you are the Biggest OEM or the small Career Inc. With the in-house development, the decision was made to develop the graphics core ourselves, which very quickly turned out to be completely correct. Otherwise we would never have become so flexible and fast. Since then, the 3DViewStation has conquered ever larger parts of the market and is not only seen as a leader by many customers.