3DViewStation Integration for Contact Software

Use all advantages of Kisters 3DViewStation in combination with CIM Database PLM

The standard viewing solution, 3D Connect, from Contact Software is sufficient for some users. But even with common assembly sizes or when more than just a few interactive functions are required, the use of the 3DViewStation makes more sense. Only 3DViewStation can meet your need for speed, rich functionality and ease of use. With it, every process participant can quickly load and analyze CAD data, prepare it for a meeting and complete their tasks with speed and efficiency. Come see how the appropriate visualization solution can facilitate more powerful collaboration and reduction of cost without ever sacrificing: quality, power or time.

Advantages for users

- Both online and offline viewing

- High-performance viewing for various 3D CAD data and 2D drawings, images and office documents

- Load most complex assemblies in 3DVS format in seconds

- 180+ interactive functionalities

- Best in class software, used worldwide, developed in Germany

- Using the Contact Activity Stream

- Intuitive operation

- Ideal for non-engineering user

Advantages for decision makers

- Perfect solution for users with native and / or complex CAD data

- Serves demanding users with advanced functionalities.

- Fast alternative to standard visualization

- Allows significantly more efficient work

- No training necessary

- More satisfied users

- Cost control: Concurrent licensing models available

For professional users with special requirements, (for example: in the field of wall thickness analysis, and for offline operation), Contact Software offers an integrated solution consisting of Kisters 3DViewStation and maintained 3D Connect integration into the world of Contact Elements and CIM Database.

The Kisters 3DViewStation extends the 3D Connect portfolio and additionally supports special analysis tasks for specialists in the development area. It offers features such as: comprehensive 3D model analysis, authoring functions as well as offline operation and visualization of native 3D models.

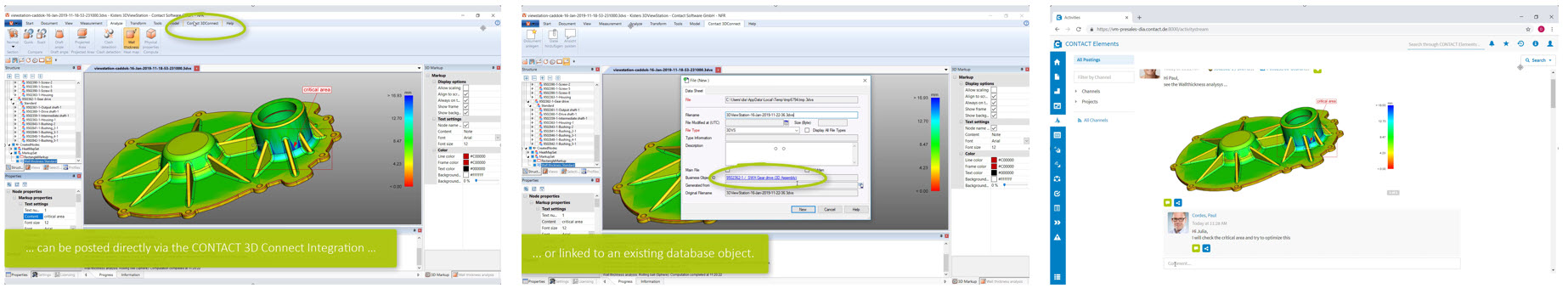

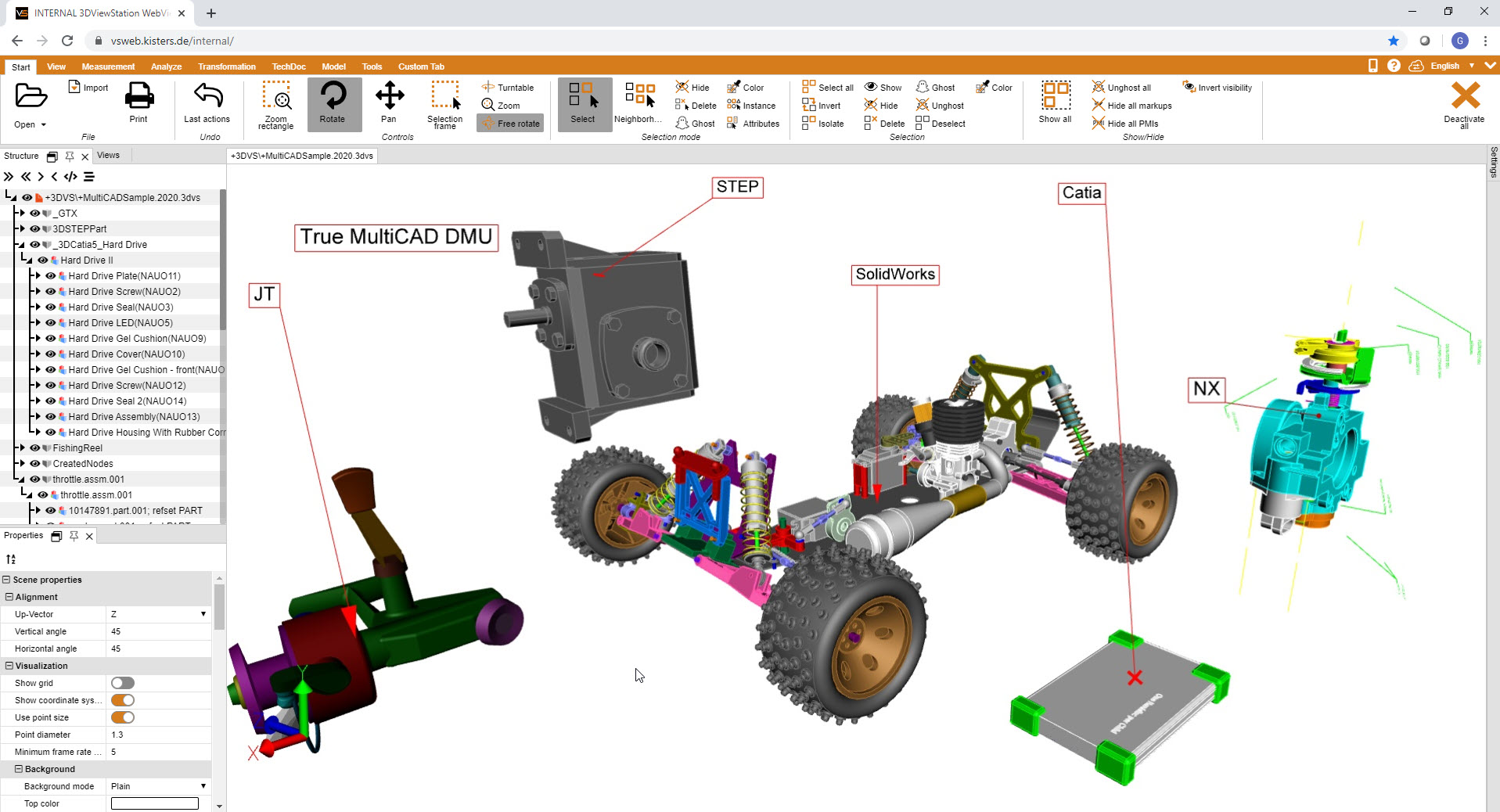

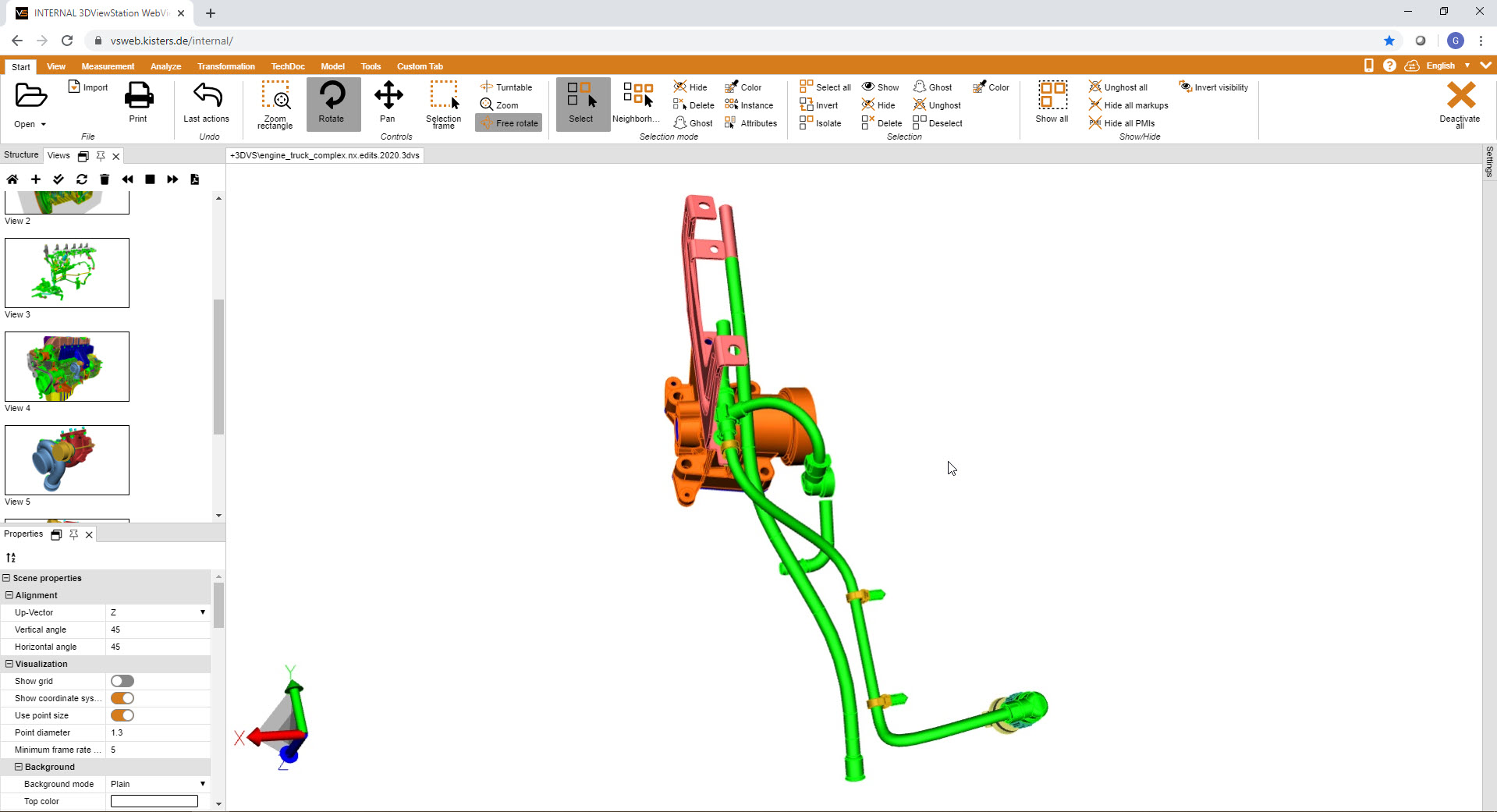

3DViewStation integrated with CIM Database

The Kisters 3DViewStation Desktop Viewer is supplied with data directly from Contact Elements and CIM Database. Modifications or accompanying information can be fed back to the data management system via the bidirectional interface. Virtual product structures can be loaded for further analysis and the results can finally be transferred into document management or communication and decision-making processes. In addition, snapshots can be posted and shared directly from the viewer via the Messenger component Activity Stream. Even though the 3DViewStation Desktop Version is integrated today, the 3DViewStation WebViewer Version could be used both online and offline due to almost identical functionalities and APIs.

Various companies from the automotive and plant engineering and electronics industries use the Kisters 3DViewStation together with Contact Elements and CIM Database. Extensions allow the user to visualize information about product configurations from PLM or ERP with 3DViewStation.

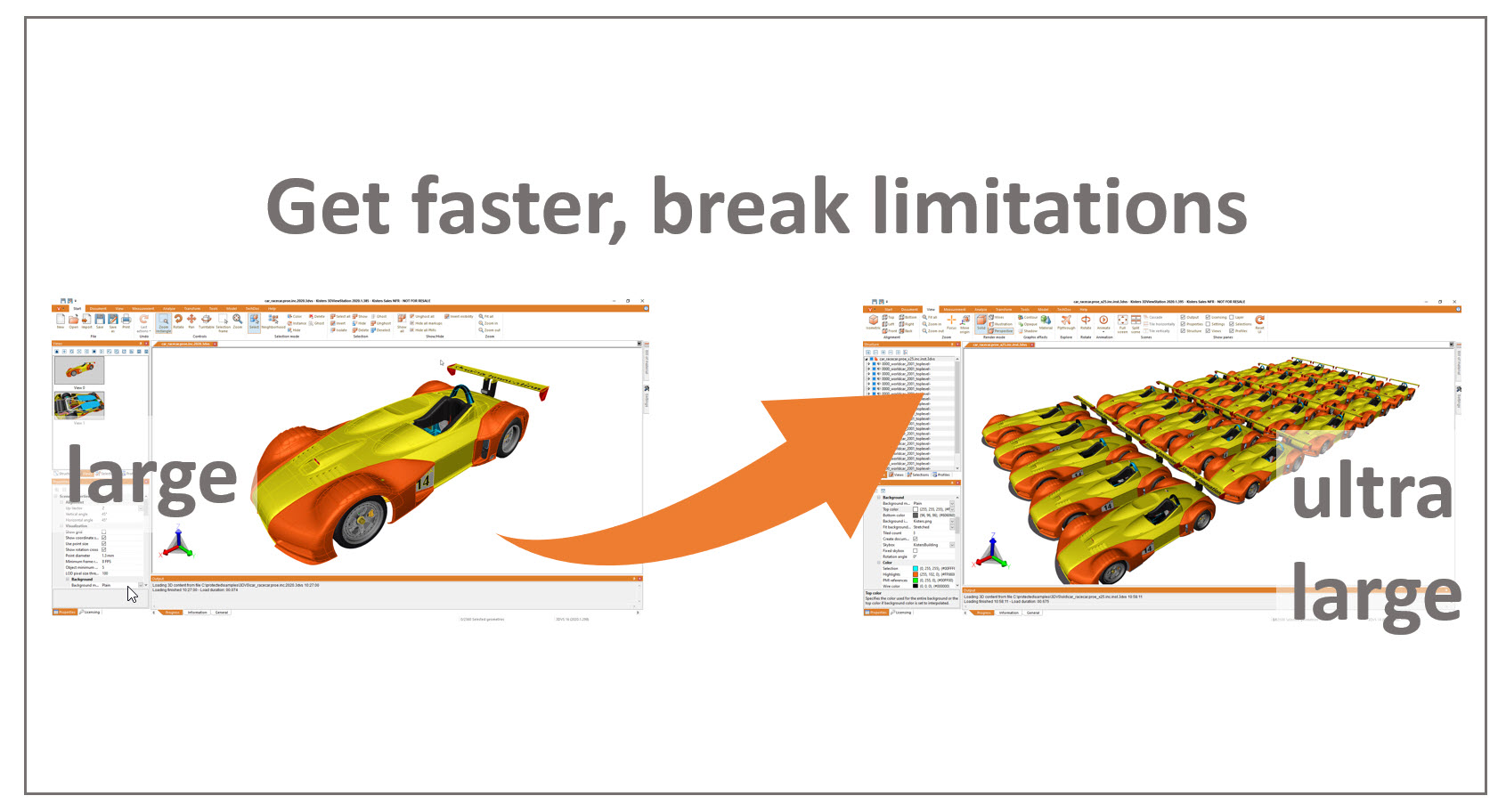

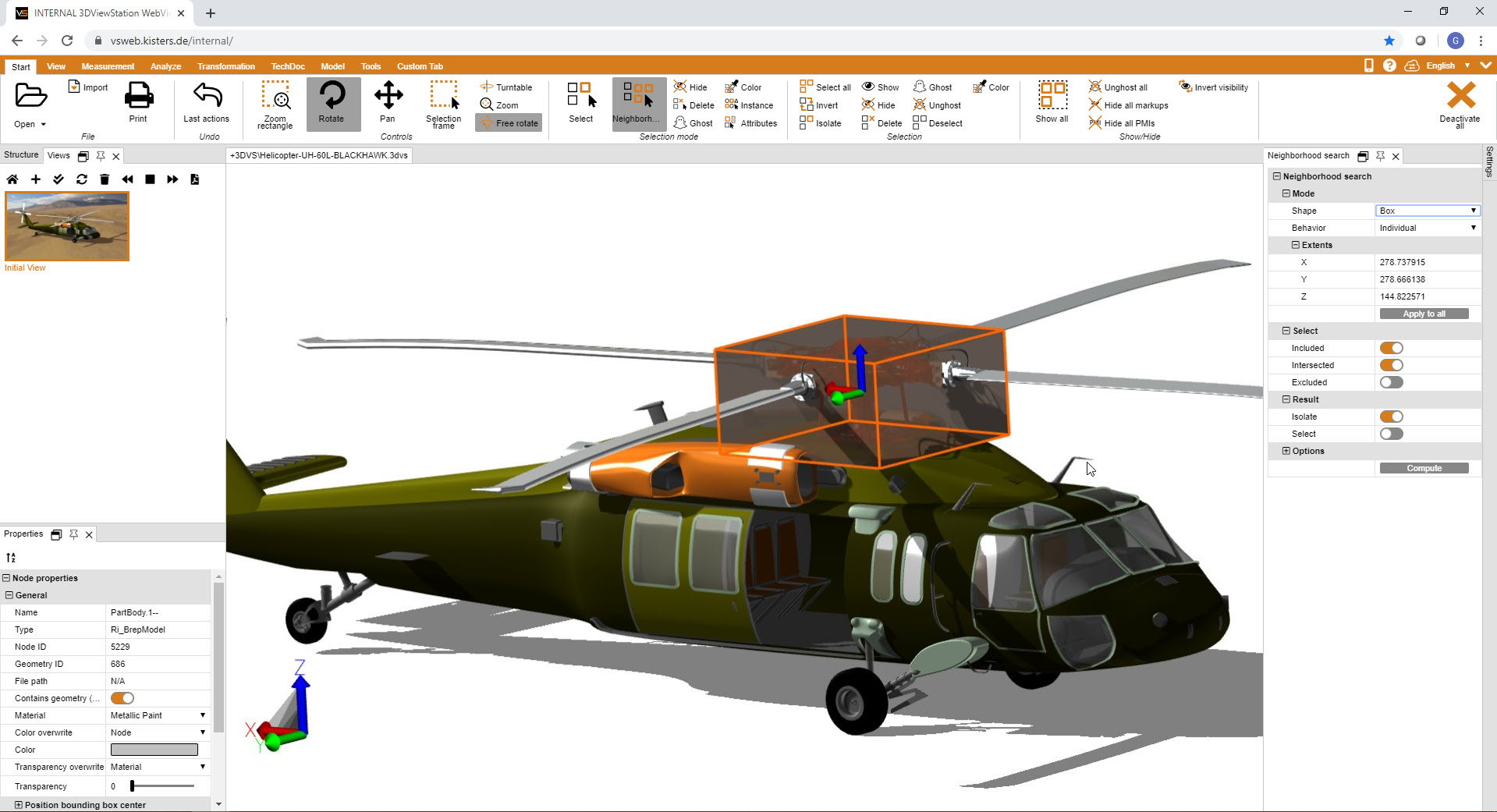

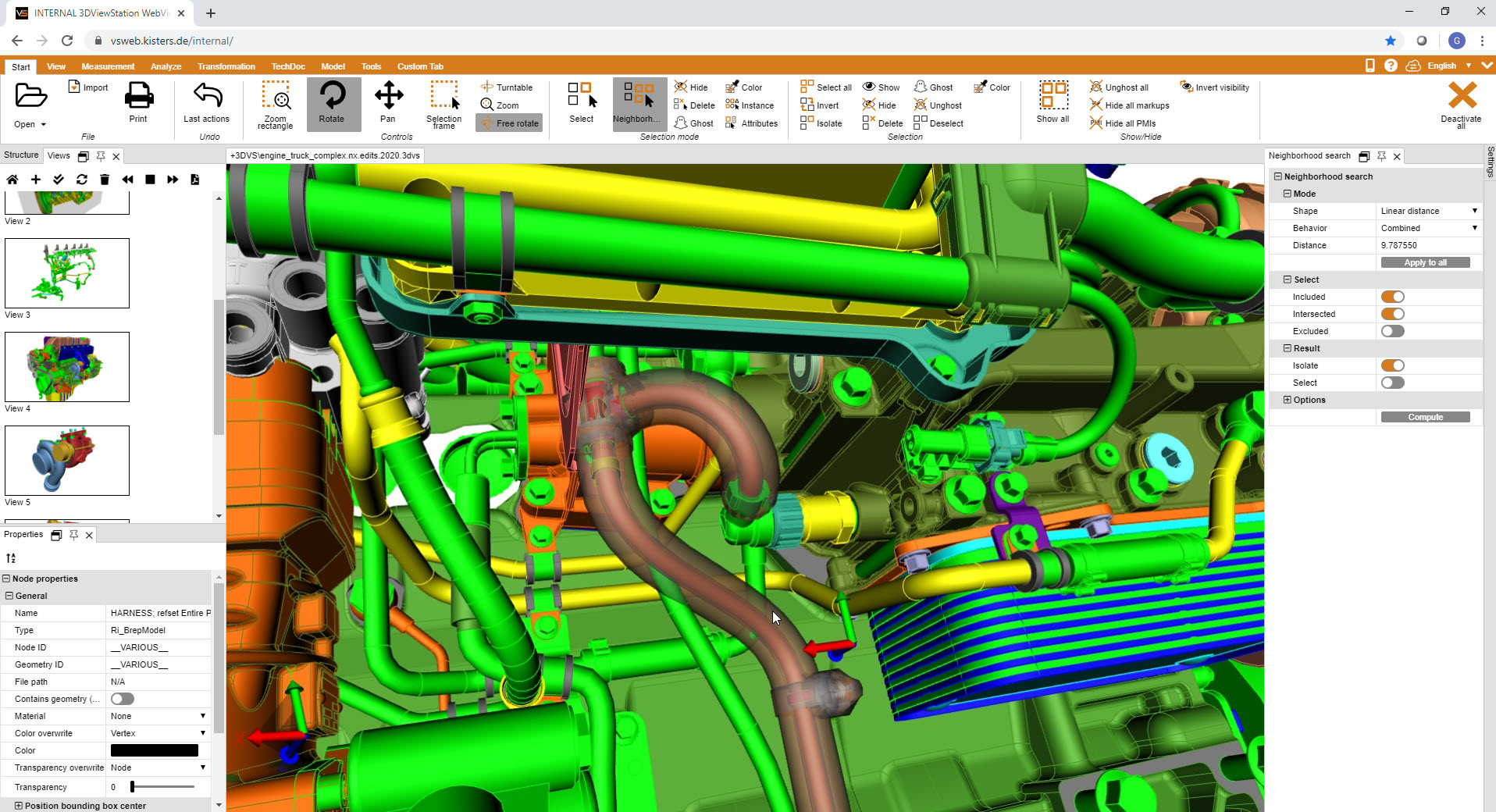

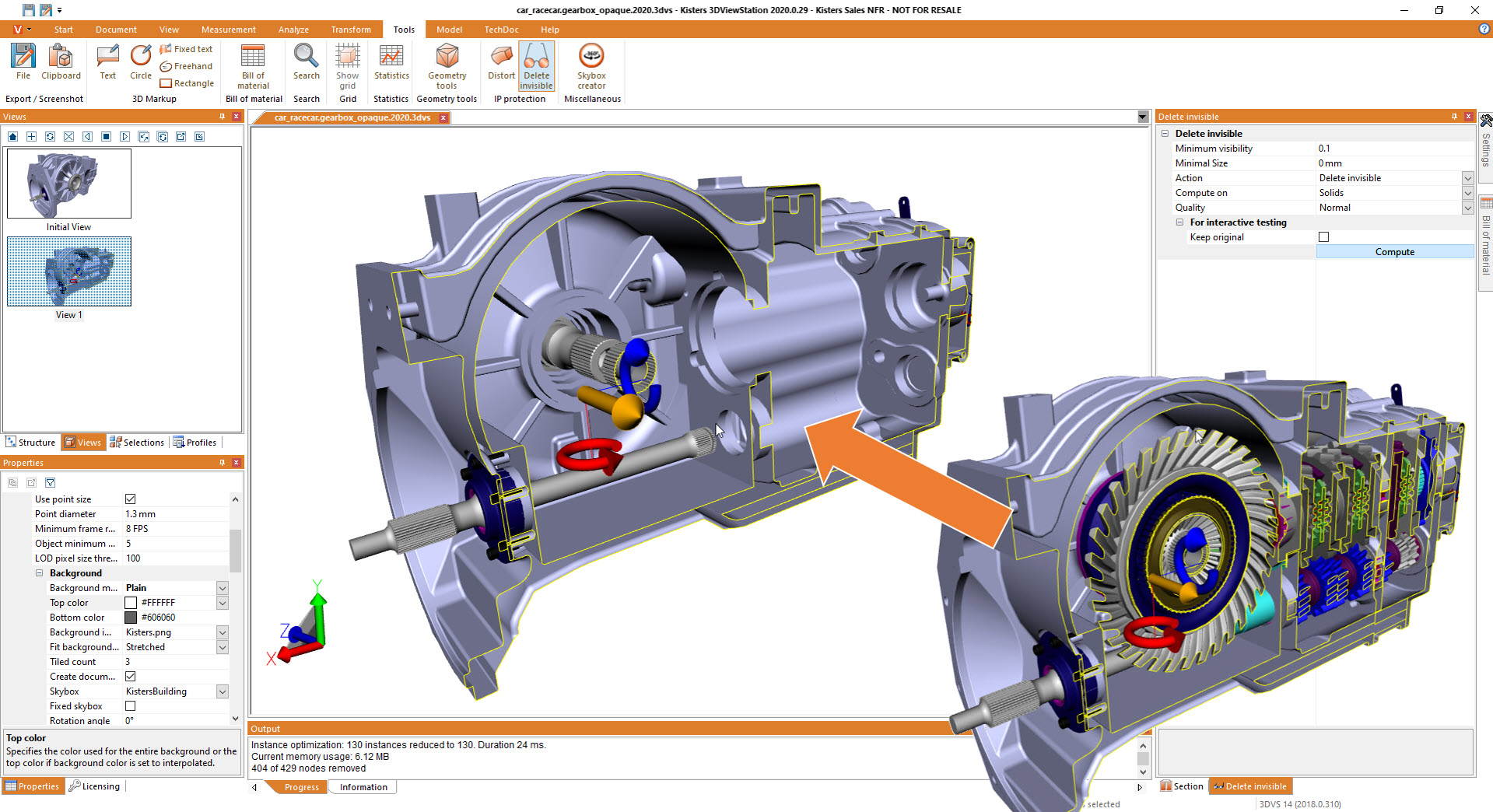

High performance viewing for CIM Database

Products developed in CAD tend to become more and more complex and therefore slower and slower to process. This not only creates problems for the CAD systems themselves, but also for all those involved and their software in the downstream processes. It is no longer enough to demand more powerful hardware, more CPUs / cores, more memory, faster computers. The answer lies in the intelligent handling of the amount of data. The 3DViewStation is a product family that can be integrated into a PDM, PLM, or g-PLM platform. With up to moderately complex CAD assemblies, we can process the data natively, i.e. directly, very quickly. If the loading time becomes longer, we recommend converting the CAD data into our own, lightweight and extremely fast 3DVS format. This conversion should not only take place when accessing for viewing, but when checking in the CAD data into the CIM database. So after the initial creation or after a change. Our batch tool KAS can be connected to the Contact conversion server for this purpose. From now on we will load assemblies with over 100,000 components in 1 second. A ship with 10 million components currently loads in 15 seconds. But we are working on reducing these times even further.

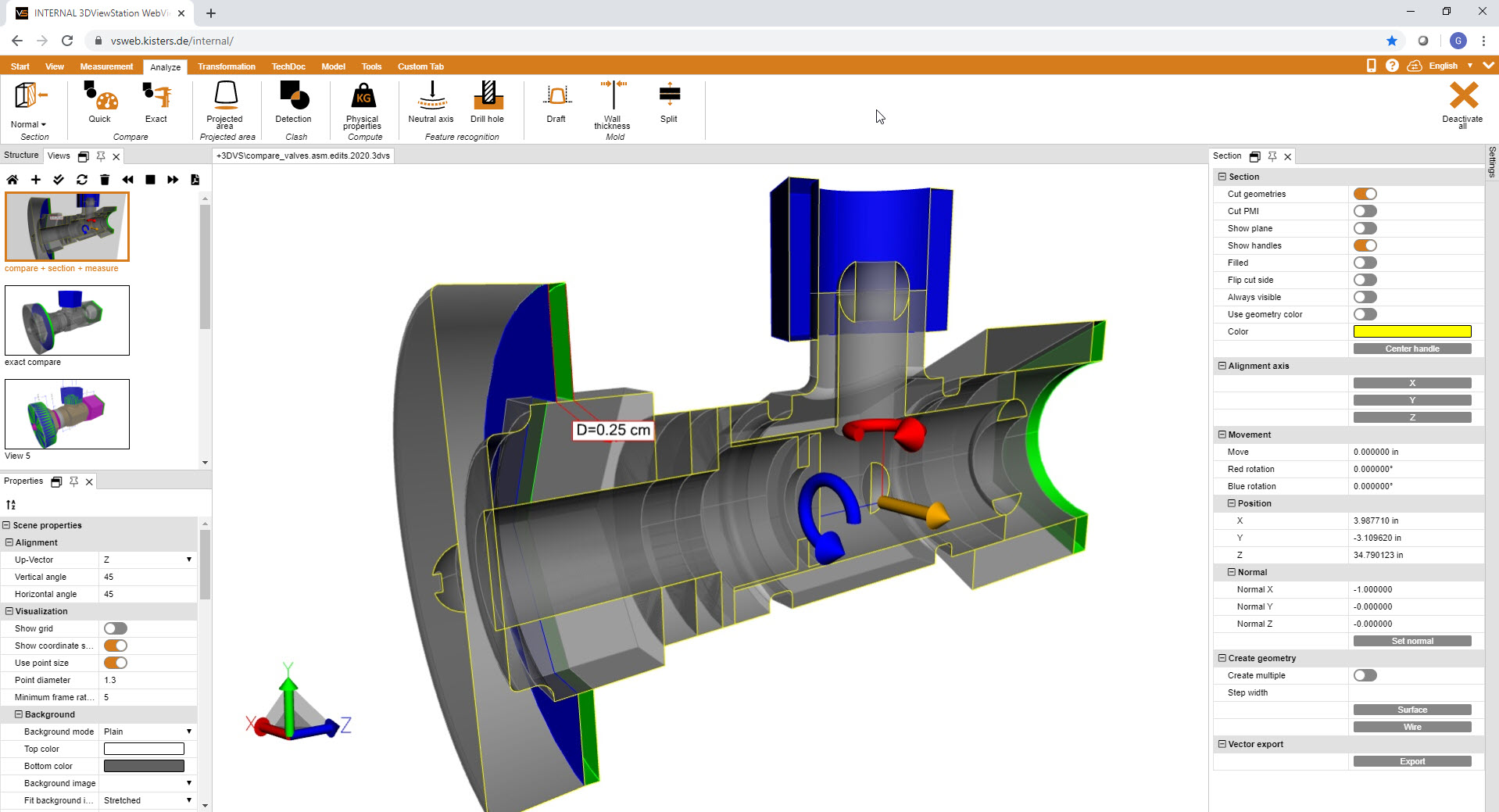

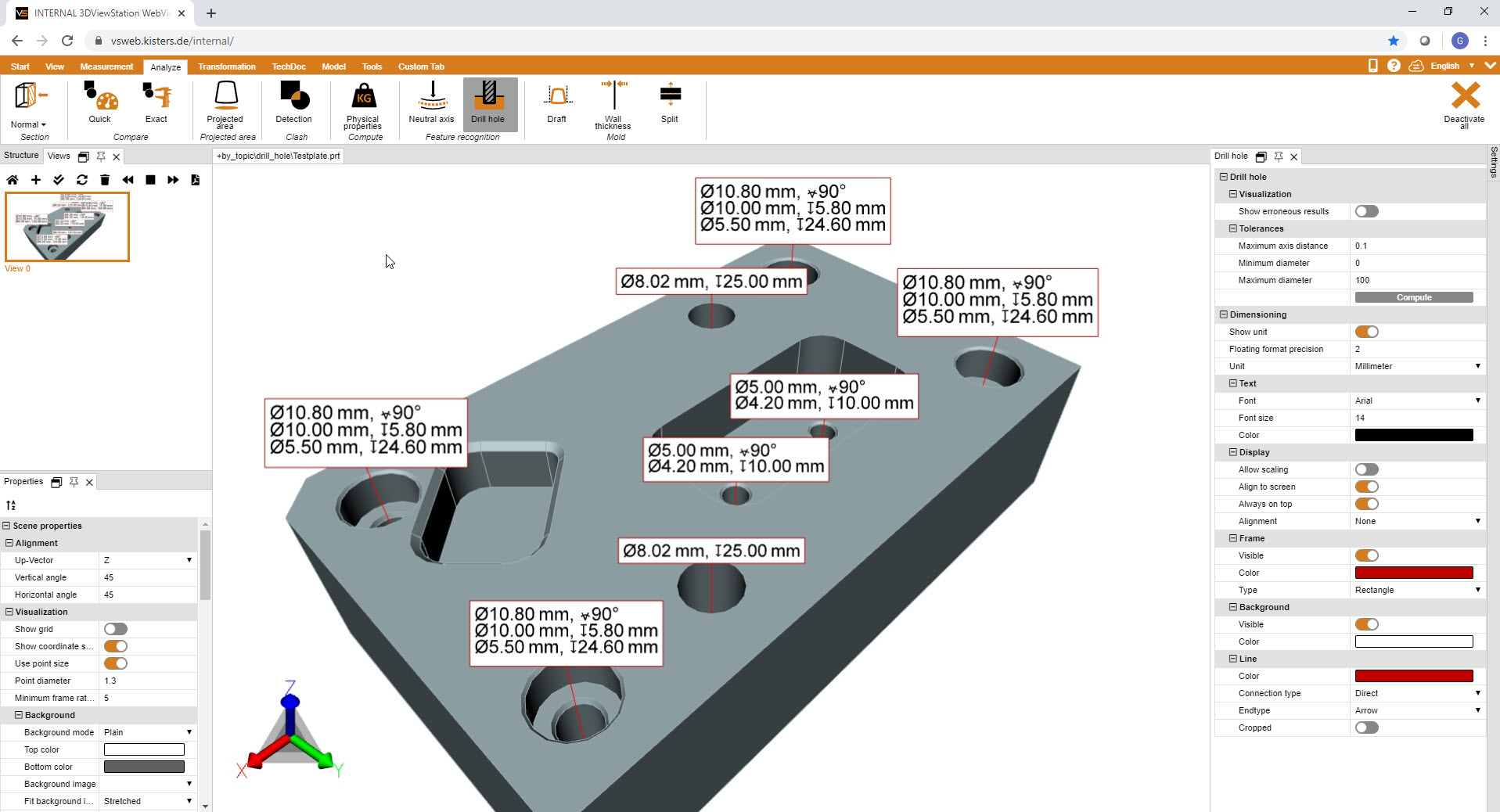

Many standard functions for everyday use

Unfortunately, fast loading alone is not enough. The users from the different processes often have very different requirements for the visualization. But there are also similarities, such as measuring, dimensioning, cutting. Or the selection of a part of objects via single or multiple click (intelligent picking), selection frame, or search & filter by name, color, attribute to name just a few. Geometrical comparisons can be used to identify differences between component or assembly versions or variants. During the comparison we allow you to cut and then measure at the same time. Even in the standard, we allow views to be created, e.g. to prepare a meeting or to initiate a change. A series of views can be used to define an assembly sequence for a component.

Advanced functions up to digital mock up (DMU)

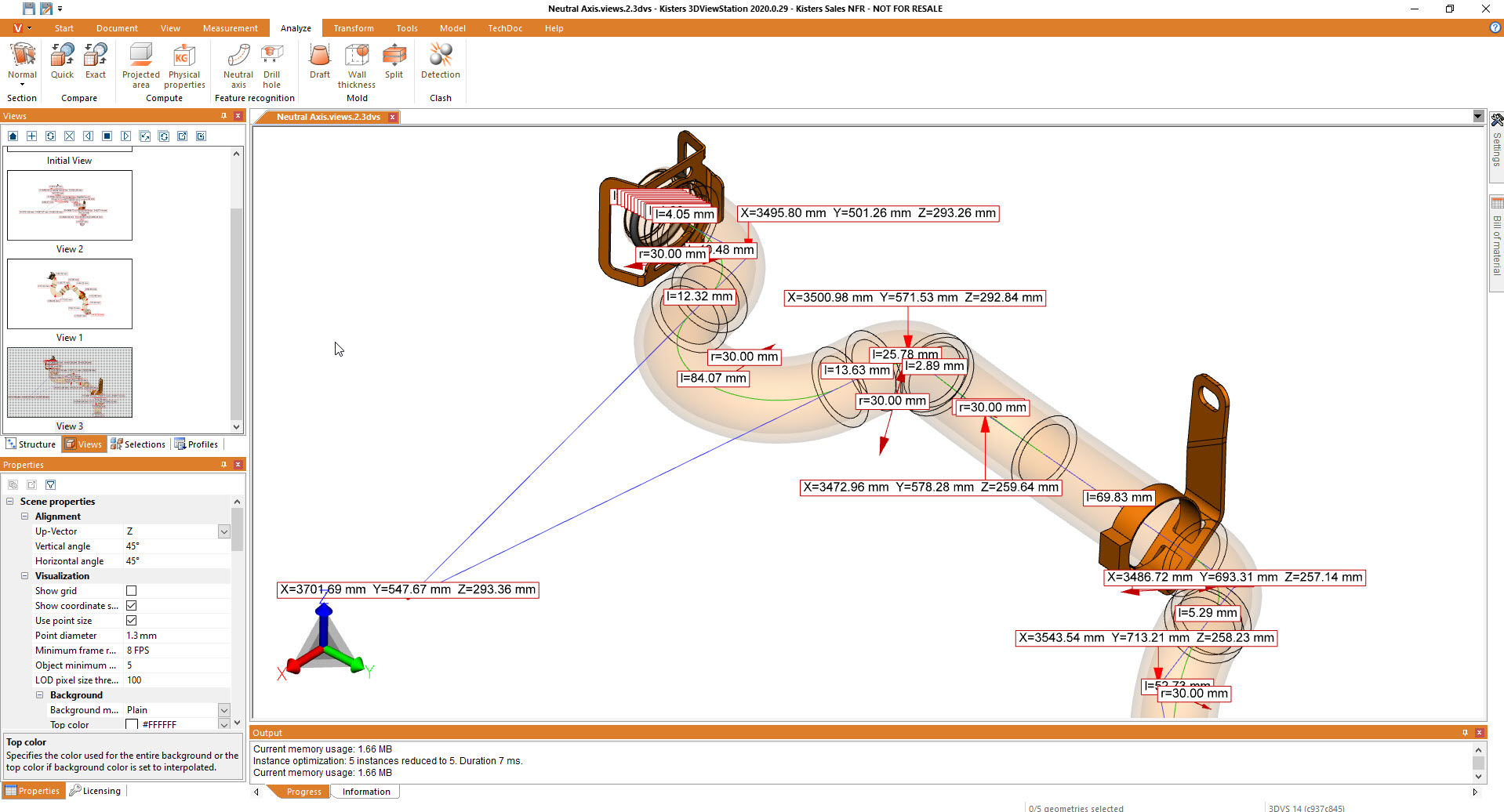

But we also offer other advanced functions that go beyond the standard. These functions are somewhat more demanding in terms of operator guidance and require some specialist knowledge of your digital product and which investigation you want to carry out with which interest. Customers from the areas of plastic injection molding, metal foundries, model and mold makers and tool makers are large user groups of the 3DViewStation. We cover various processes here. The sales colleague receives native CAD data for his quotation calculation. He has to measure, calculate volumes and make 3D annotations on the model.

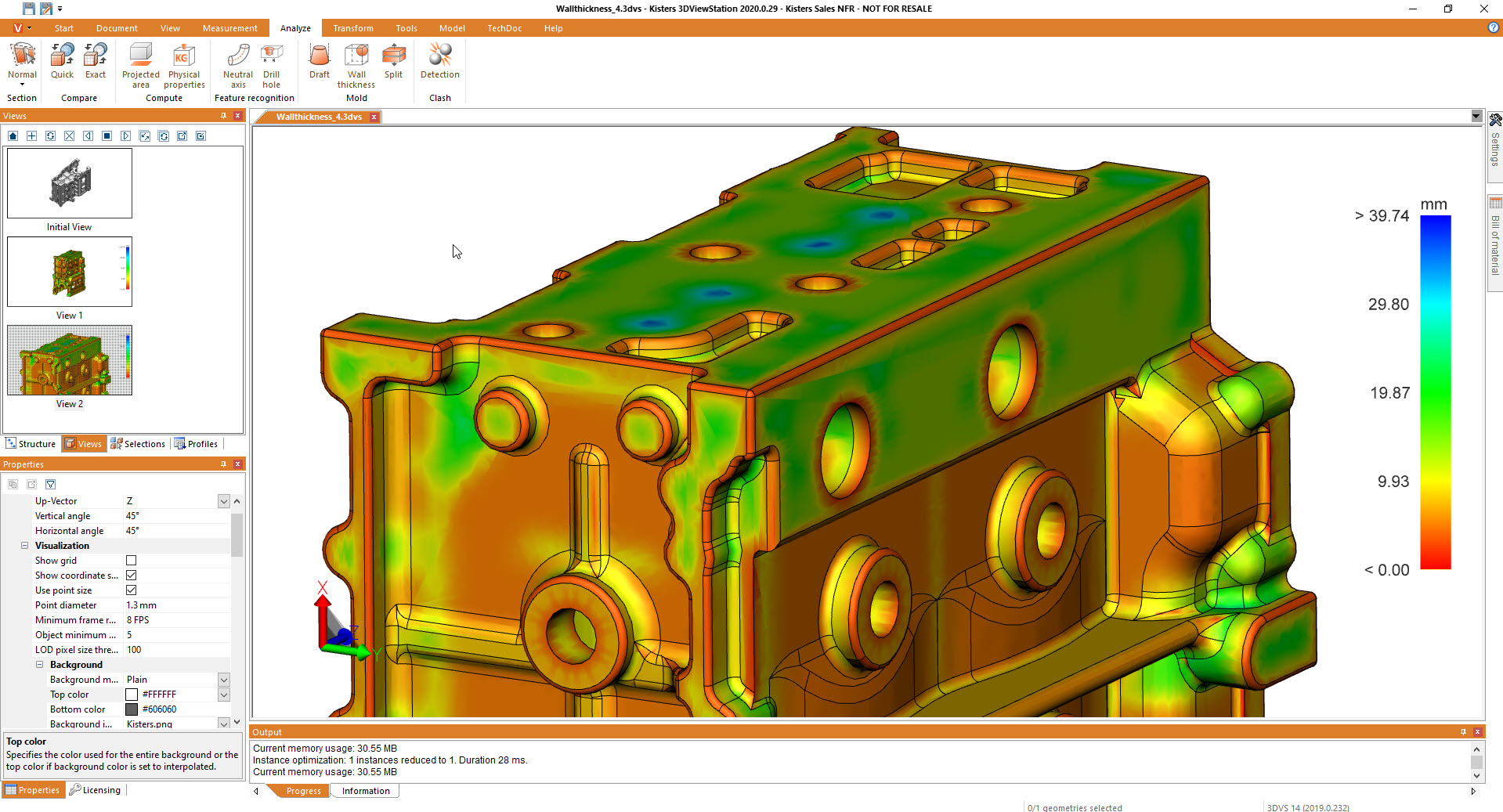

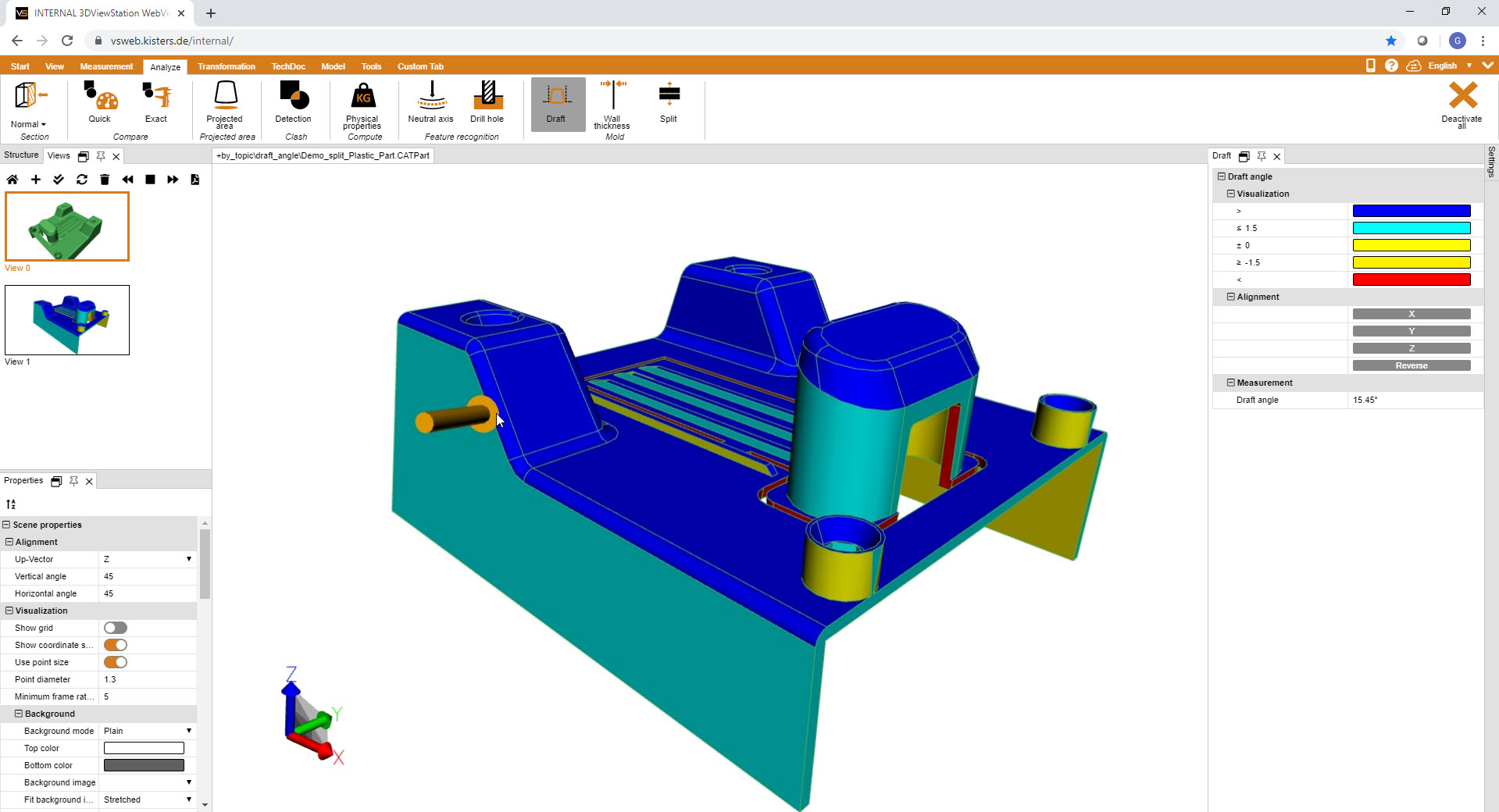

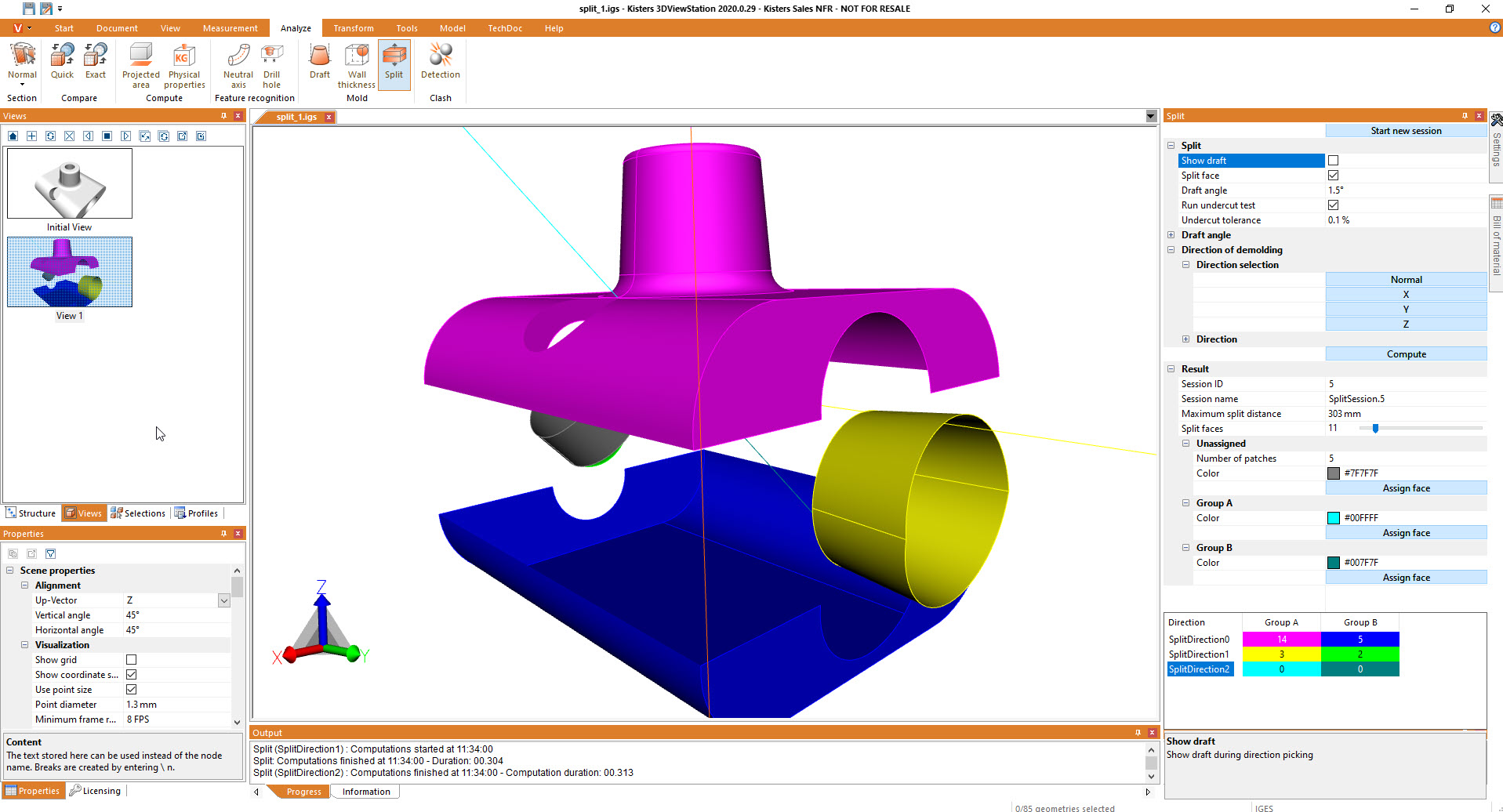

Wall thickness analysis, split, draft angles, undercuts

Using the wall thickness analysis, he can identify critical, e.g. too thin, areas in the CAD model. If the company receives the order, it must be able to compare the CAD data sent with the original. Another colleague wants to determine the complexity of the shape and the tools required for production. Using a draft angle analysis, he can carry out initial investigations and identify problematic undercuts. It uses our split function to separate the surfaces of the required shape. Now he can see how many slides his tool will need to be able to demold the component again.

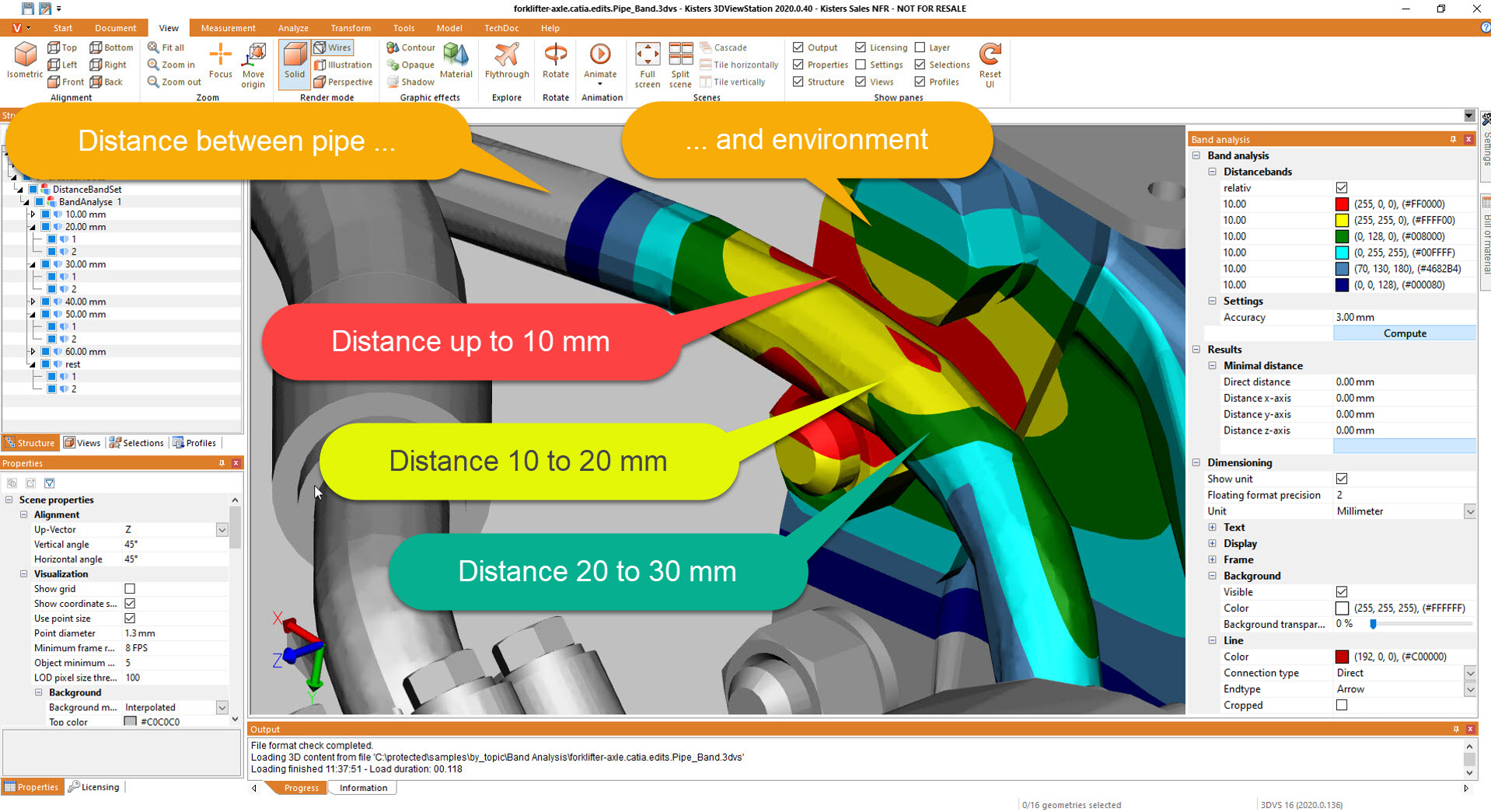

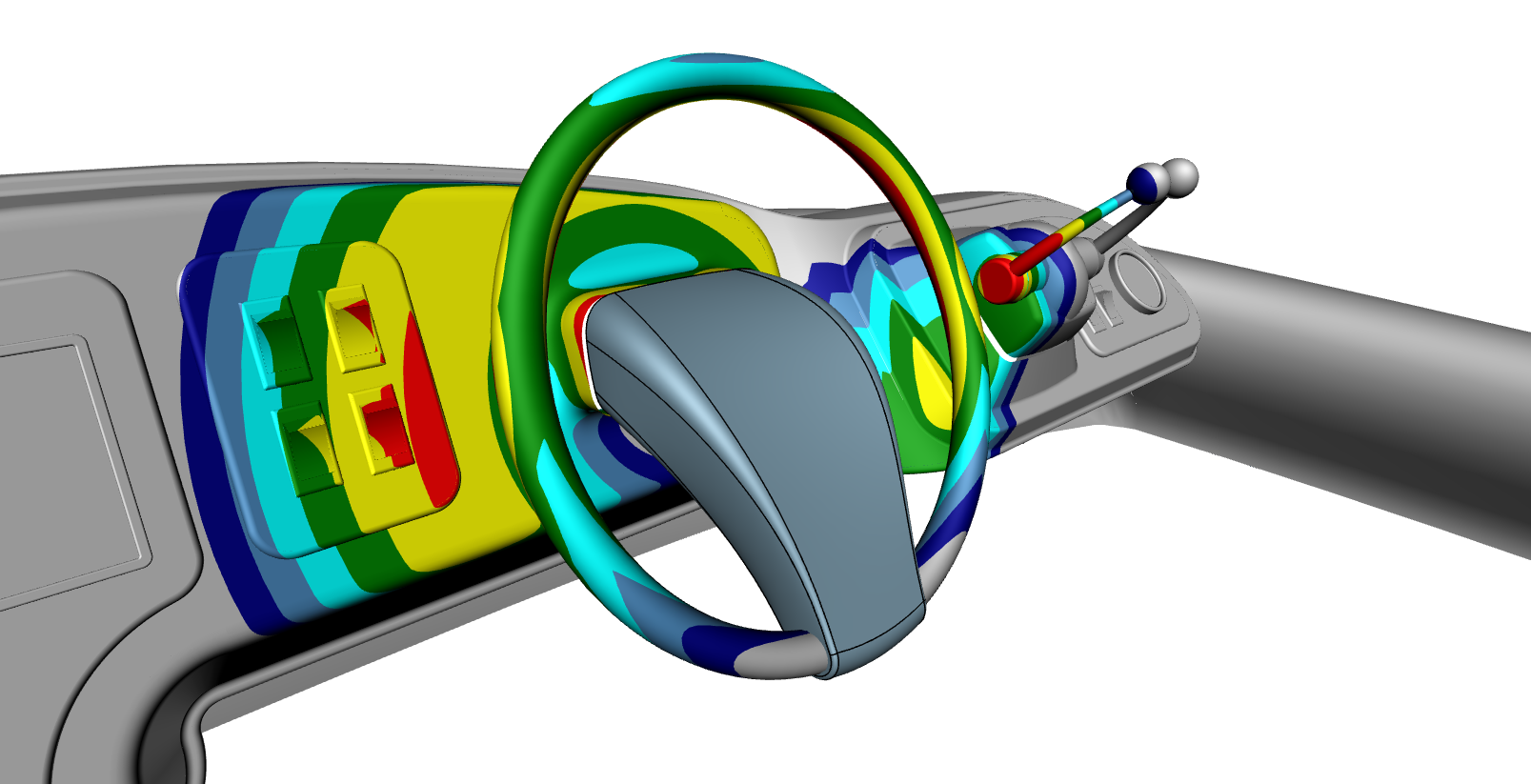

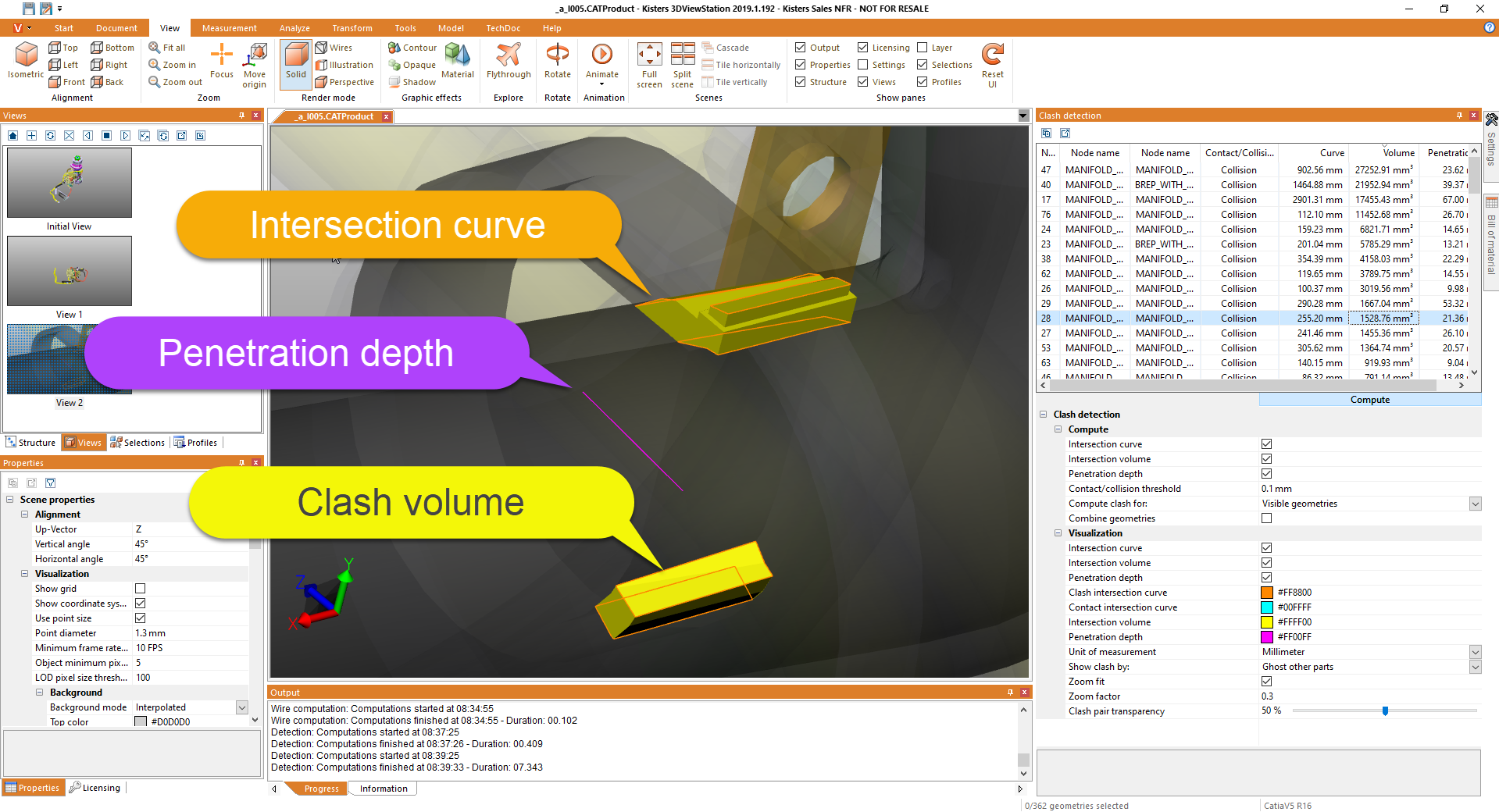

Clash & Clearance Investigations

Clash & clearance examinations can also be carried out with the 3DViewStation. In this way, the responsible project leader can identify problem areas in an assembly himself or in the installed state long before production. He can first have it examined and sorted according to collision or contact. Further calculations determine the contour or the volume of the collision and also the penetration or penetration depth. This gives the shortest path that is required to cancel the collision. The clearance analysis, on the other hand, shows whether certain distances can be maintained. This is achieved using colored spacer strips. Such examinations are often used for exhaust systems in vehicles, pipelines in buildings, ergonomics in the cockpit, distances within a robot cell, etc. employed. Please visit our BLOG again and again to find out about the latest developments.

3DViewStation for IoT

The 3DViewStation is also used in the IoT environment. It is quite easy to locate a sensor within a 3D model that is currently reporting problems. For this purpose, the sensor can be highlighted in color, the rest of the model can only be displayed as a contour (ghost), and the sensor can be zoomed if necessary. Since everything happens automatically, of course, controlled by our APIs. By clicking on the sensor, for example, live data can be called up or historical data can be displayed. Maintenance or repair instructions can also be called up with a click. Since the 3DViewStation also runs on smartphones without any local installation and without local data, a service technician can also be notified in the event of a fault, who can recognize on his smartphone or tablet before the trip to the customer what the problem is and whether a repair is possible with the existing one Spare parts is possible at all.

We would be happy to advise you

Sales Germany

+49 2408 9385 517

Sales USA

+1 916 723 1441

For more information about 3D visualization and the Kisters 3DViewStation integration, see

https://www.contact-software.com/de/elements/core-services/3d-visualization