面向售后/MRO、服务和备件领域的可视化

将 3DViewStation 用作售后、服务和备件解决方案的可视化系统。

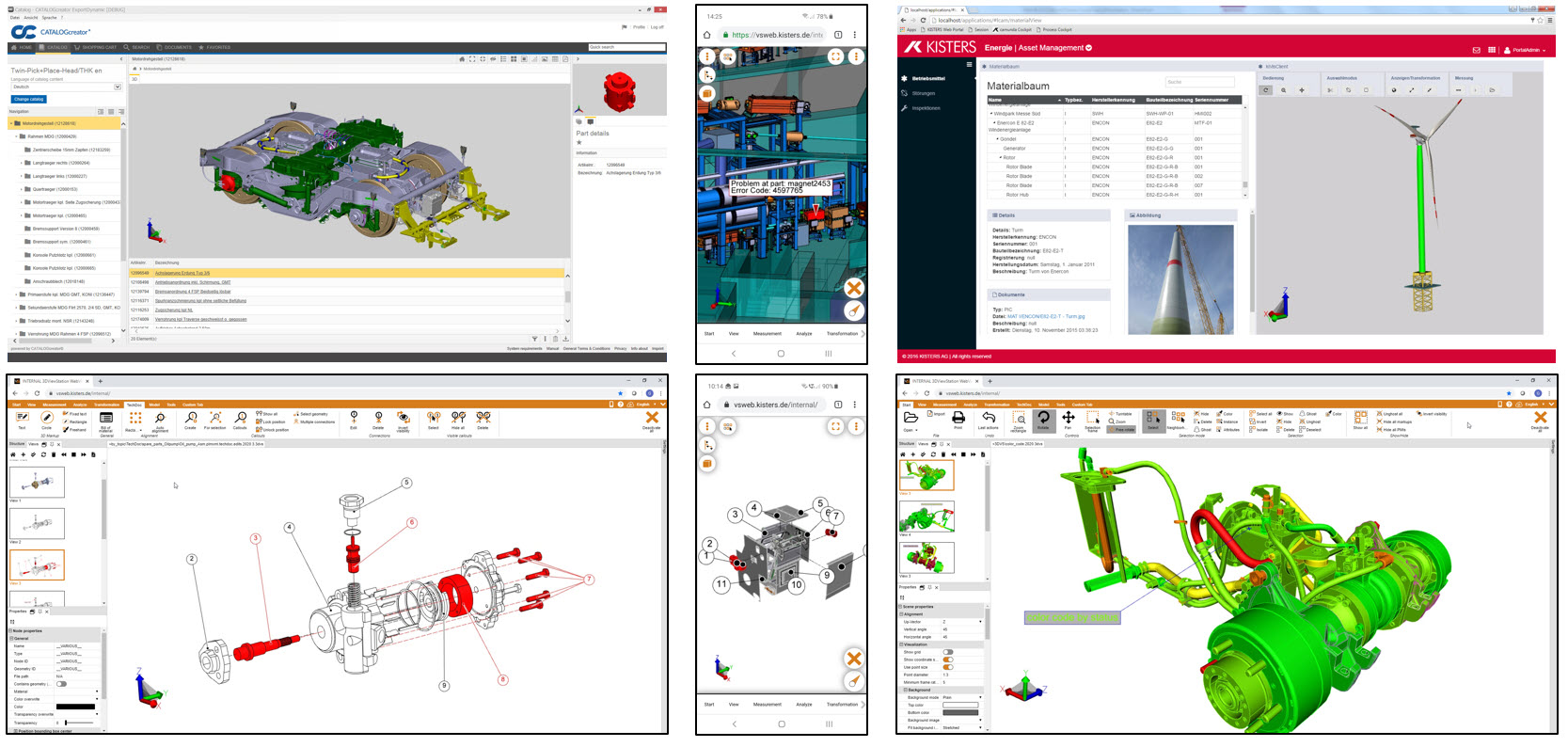

为一个复杂的产品提供信息、措施和服务是当今每个公司的客户所期望的。通过直观的用户指导轻松进入在线系统,促进了备件的购买,并导致了客户的忠诚度,这比一份新的信件更好。对于美国常称为 MRO(Maintenance-Repair-Overhaul)<g id="50"> </g>的售后解决方案,必须将不同源系统的数据和信息汇总到一起。如今,许多应用程序只是缺少一个可以用来可视化显示对应的 CAD 数据的图形组件。这一点对于某些服务应用程序是一样的,这些应用程序常会向正在出差的技术人员发出警报,但通常情况下仅能告知客户名称和错误代码。但是,增加一个3D图形来表示产品,可以带来决定性的优势,因为一方面你可以看到问题存在的空间位置,也可以从几何形状链接到故障排除或维修的说明。但是,最好是使用相应的作者系统来尽可能以 3D 形式创建不同说明书的图形内容并加以维护,由此还能减少花在零件目录上的工作量,这种零件目录如今作为无插件的纯 Web 应用程序运行。在这种情况下,3DViewStation 的所有产品变型都适用。

我们很乐意为您提供建议

技术

+49 2408 9385 517

福利...

... for users

- 该产品系列可用于处于所有作者任务

- 无插件的 HTML5 浏览器足以完成可视化显示

- 可完全集成到主系统的界面中

- 即使是极其复杂的产品,也能迅速获得视觉印象

- 可帮助服务技术人员更好地进行故障评估

- 始终可访问最新信息(在线使用时)

- 操作便捷

... 对于开发者来说

- 集成模块可将来自多个系统的数据合并到一起

- 面向作者系统和最终用户系统的集成

- 可快速实施集成

- 由于没有 SDK,因此只需几行编程代码即可

- 在桌面版和 Web/移动集成版之间切换时,仅需进行少量调整即可

- 高水平的咨询团队可帮助解决集成方面的所有问题

... 决策者

- 获得和保留客户

- 营销和销售备件和服务

- 使用100%的备件BOMs

- 对3D和2D的最终结果只有一个解决方案

- 在线使用可避免使用过时的数据和信息

- 在线和离线使用的概念

- 服务小组的救济

- 许多自动化的可能性

- 不需要培训

- 无需安装客户端(使用WebViewer)

项目实例

问题是。

Quanos(原TID Informatik)以前的CatalogCreator三维浏览器需要一个必须在本地安装的插件,而且必须在本地访问要可视化的数据。为了消除这一限制,我们寻求一种HTML 5解决方案,它只需要一个现代浏览器,但不需要客户端安装。

解决办法。

Quanos已经决定使用3DViewStation WebViewer版本。它是一个HTML 5解决方案,可以在个人电脑和移动设备上使用,而不需要在终端设备上使用一个以上的浏览器。通过3DViewStation,三维CAD数据可以直接从不同的三维CAD系统加载。如果有非常复杂的装配体,可以使用批处理工具KAS对其进行预转换,即使是最大的装配体,其加载时间也能缩短到几秒钟。

其好处是。

有了3DViewStation WebViewer版本,CatalogCreator现在可以在任何终端设备上操作,甚至在智能手机和平板电脑上。较短的加载时间确保了用户的高接受度。由于 3DViewStation 也可以离线运行,并且在制作备件数据的时候可同时作为作者系统使用,此外还拥有目前仍在使用的 2D 格式导出选项,因此成为了一种理想且面向未来的解决方案。

问题是。

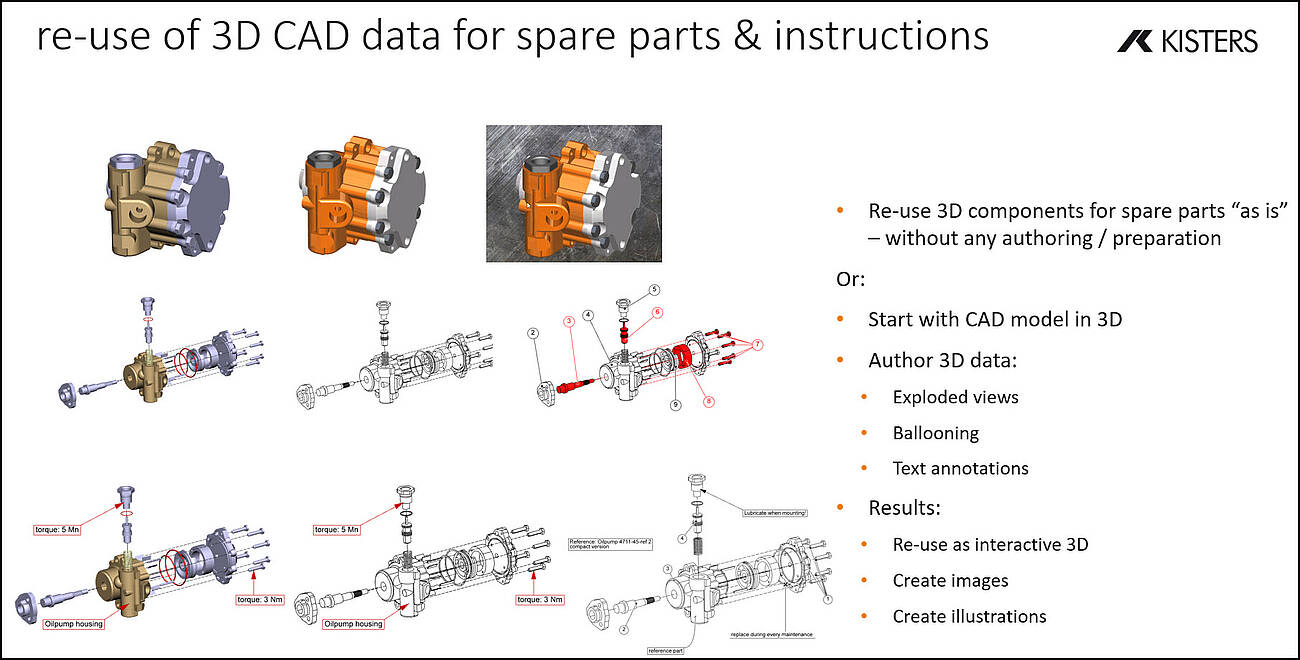

今天,汽车环境中的拖车、车身、农用车以及配件的制造商通常都有数字化的备件解决方案,但纯粹是基于2D的。通常情况下,使用的是部分来自CAD数据的图像。有时会使用矢量图,例如SVG格式,它至少可以有超链接。然而,随着向三维CAD的不断转变,这种内容已经过时了,而且由于必要的准备工作,成本太高。

解决办法。

在这里,3DViewStation通常既是一个创作系统,也是一个纯粹的查看器。最初,可以通过从以前的数据格式的三维CAD数据中创建内容,无论是图像还是矢量,都可以支持旧的方式。然而,3DViewStation也可以使3D内容看起来像2D插图,这意味着,如果要逐步和更不明显地进行转换,不一定非要让人看到。

其好处是。

3DViewStation支持两种方式,即传统的2D和3D方式,也支持平稳过渡。然而,从长远来看,全面转向3D更具有成本效益和未来性。这是因为再处理所需的努力往往被大幅减少或完全避免。

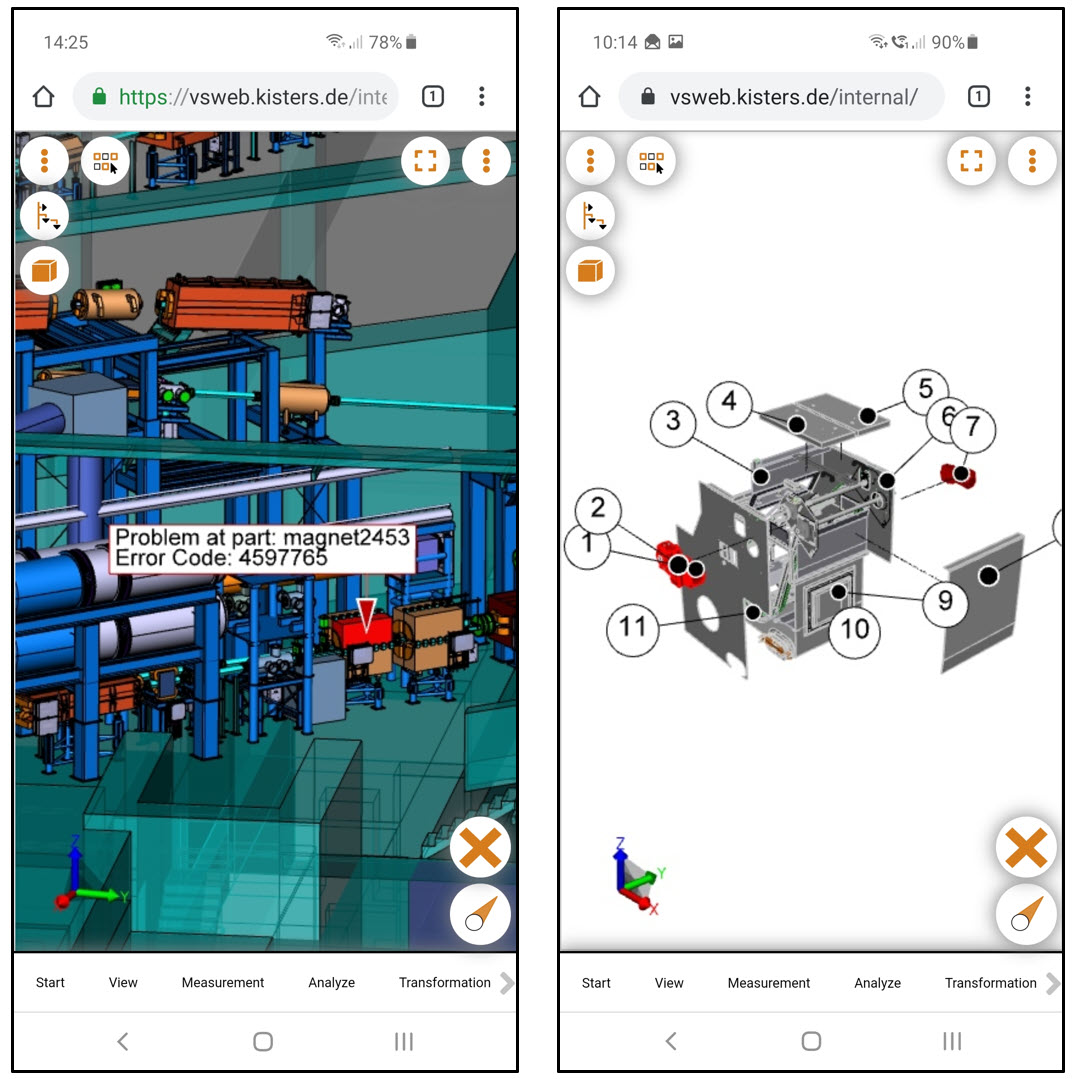

问题是。

今天,机器制造商使用电子邮件,也使用应用程序来通知其服务人员必要的操作。然而,通常情况下,只提供客户的名字和地址,也许还有机器的类型。然而,通常情况下,如果服务人员能够在路上就评估出问题到底是什么以及如何解决,这可能是一种优势。以及是否需要备件,没有备件就不可能进行维修。这就要求图形即使在智能手机上也能运行,而且还能在低带宽下运行。

解决办法。

有了3DViewStation WebViewer版本,服务员工在路上就可以准确地看到机器中出现问题的地方。他现在可以访问相关组件的当前和历史状态信息。他从一个零件接收到相关的维护和故障排除文件以及所需备件信息的链接。

其好处是。

即使在路上,也可以更好地评估即将到来的任务。如果清楚地知道将需要备件,就可以避免当时的无意义的使用,从而节省成本。由于一些机器制造商也在机器本身上操作3DViewStation,这种解决方案的额外费用可以忽略不计。

问题是。

几年前,道依茨公司从二维备件文件转换为三维文件。为此,首先用创作系统准备数据,然后用查看器在浏览器中显示。然而,由于该查看器是一个ActiveX组件,只能在Internet Explorer中运行,因此需要寻求一个面向未来的HTML 5解决方案。

解决办法。

在将产品配置器转换为Kisters 3DViewStation的背景下,很明显,现在也将3DViewStation WebViewer版本用于售后和服务领域。

其好处是。

对于终端设备的浏览器或操作系统不再有任何限制。为此,配置过程中的可用数据可以用于备件应用,而无需进一步处理。

问题是。

今天,许多手册和技术文件仍在印刷或以二维方式出版。内部部门经常从事内容工作,但也有许多外部服务提供商。同事们经常收到三维CAD数据,他们必须自己从中得出图像或矢量插图。然后,这些内容往往被转移到编辑系统或直接纳入文件中。由于编辑不是CAD专家,他们需要一个易于使用的工具来完成他们的工作。

解决办法。

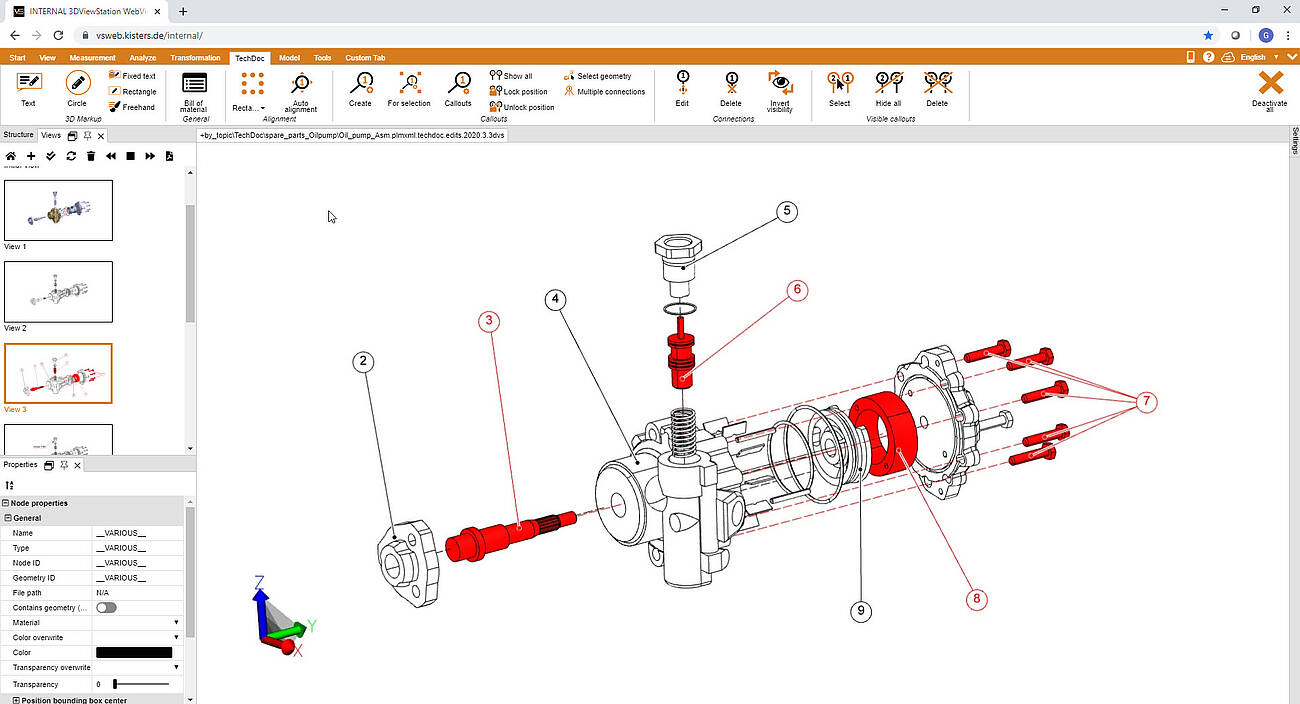

这里经常使用Kisters 3DViewStation桌面版。可以读取和准备来自广泛的CAD系统和中性格式的2D和3D CAD数据。这包括隔离子装配,改变颜色或透明性,添加注释或独立的文本,爆炸装配和添加项目编号图形。各个处理步骤是在视图中创建的,然后以各自所需的数据格式作为图像或矢量图输出。

其好处是。

通过一个直观的工具,来自各种来源的三维CAD数据可以被快速和容易地准备。此外,3DViewStation比CAD系统更便宜。

问题是。

海上风电场必须定期得到检查。为此,往往需要一个检修系统,其可用来对这些检查进行规划并将结果记录在案。为了能够更好地分配报告和问题说明,希望有一个三维视图,与通过文本搜索或只通过建筑群结构树相比,用户可以更容易地导航到工厂的组成部分。同时,应在文字和几何对象之间建立联系。

解决办法。

3DViewStation WebViewer版本已经完全集成到维护解决方案LCAM的界面中。点击一个几何图形,所属的组件将立即在 LCAM 中高亮显示,反之亦然。同时,将列出为该组件所保存的图片、文档和报告,并且可以附加新报告。

其好处是。

用户现在可以选择几种方式来获得他需要的信息。通常情况下,通过3D图形的方式是最快的,因为你只需在查看器中选择组件,而不必知道确切的名称并搜索它们。解决方案的开发者们也很惊讶,这里的基本整合只花了几个小时。