La collaboration CAO 3D en ligne présente de nombreux avantages...

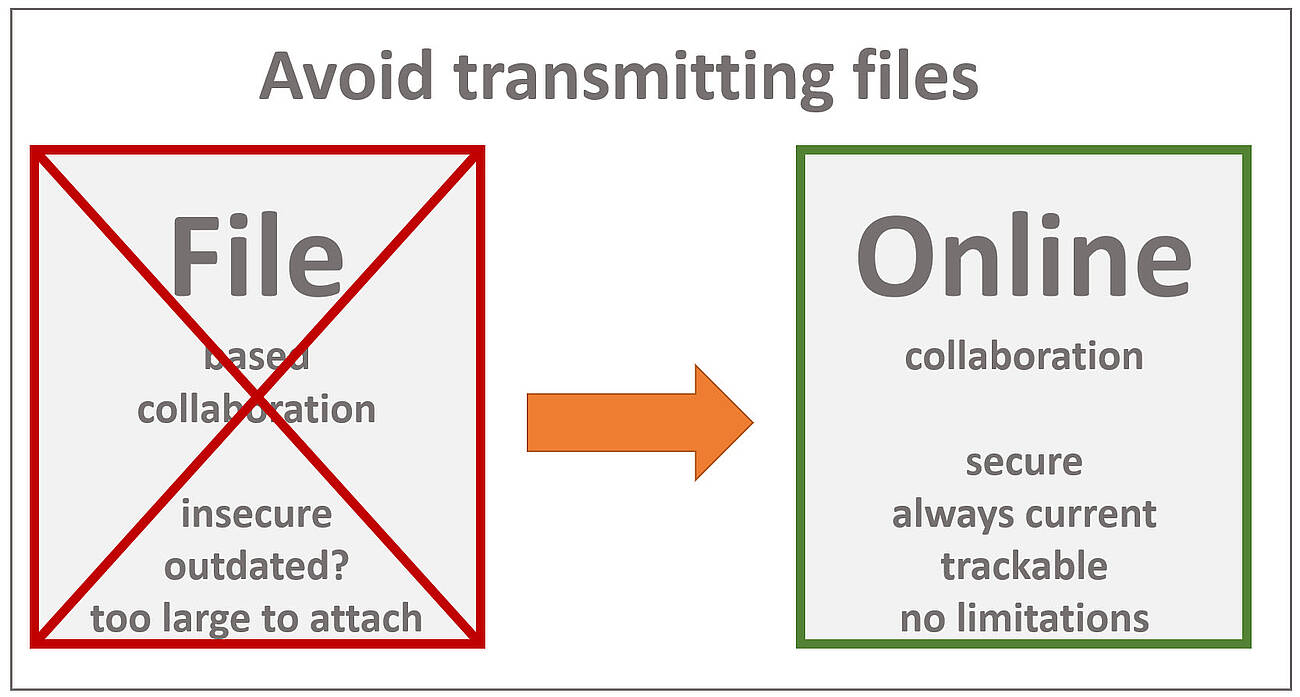

... par rapport à l'envoi de fichiers CAO 3D

Dans l'industrie manufacturière, il est courant d'échanger des fichiers CAO 3D. Mais est-ce toujours nécessaire ? N'est-il pas plus avantageux de travailler ensemble en ligne ?

Bien sûr, il existe des cas d'application où des fichiers CAO natifs comme Catia ou Inventor ou des données CAO 3D neutres comme STEP sont nécessaires. Par exemple, pour concevoir un moule ou un outil ou pour fabriquer une pièce spécifique. Pour d'autres cas d'application, probablement la plupart, nous n'avons pas besoin de la géométrie exacte (BREP), car des modèles légers sont amplement suffisants. Ainsi, les fichiers JT, 3D-PDF ou eDrawing sont échangés, sachant qu'il existe des visionneuses gratuites comme JT2Go ou Acrobat Reader. Cependant, ces visionneuses ont en commun le fait qu'elles nécessitent une installation locale. Et ils pourraient également avoir des limitations, comme des fonctionnalités limitées et différentes. Ou bien ils ont des performances insuffisantes, des problèmes d'accès mobile et de téléchargement de fichiers, un chargement et un téléchargement compliqués et longs d'assemblages volumineux, des risques de protection du savoir-faire...

C'est pourquoi nous pensons que dans de nombreux cas, il est plus judicieux et en même temps tout à fait suffisant de simplement donner accès aux données CAO 3D nécessaires. Vous pouvez les consulter, les vérifier et travailler avec eux - en ligne, sans téléchargement.

Vous trouverez ci-dessous quelques raisons supplémentaires d'aller en ligne plutôt que d'échanger des fichiers CAO 3D :

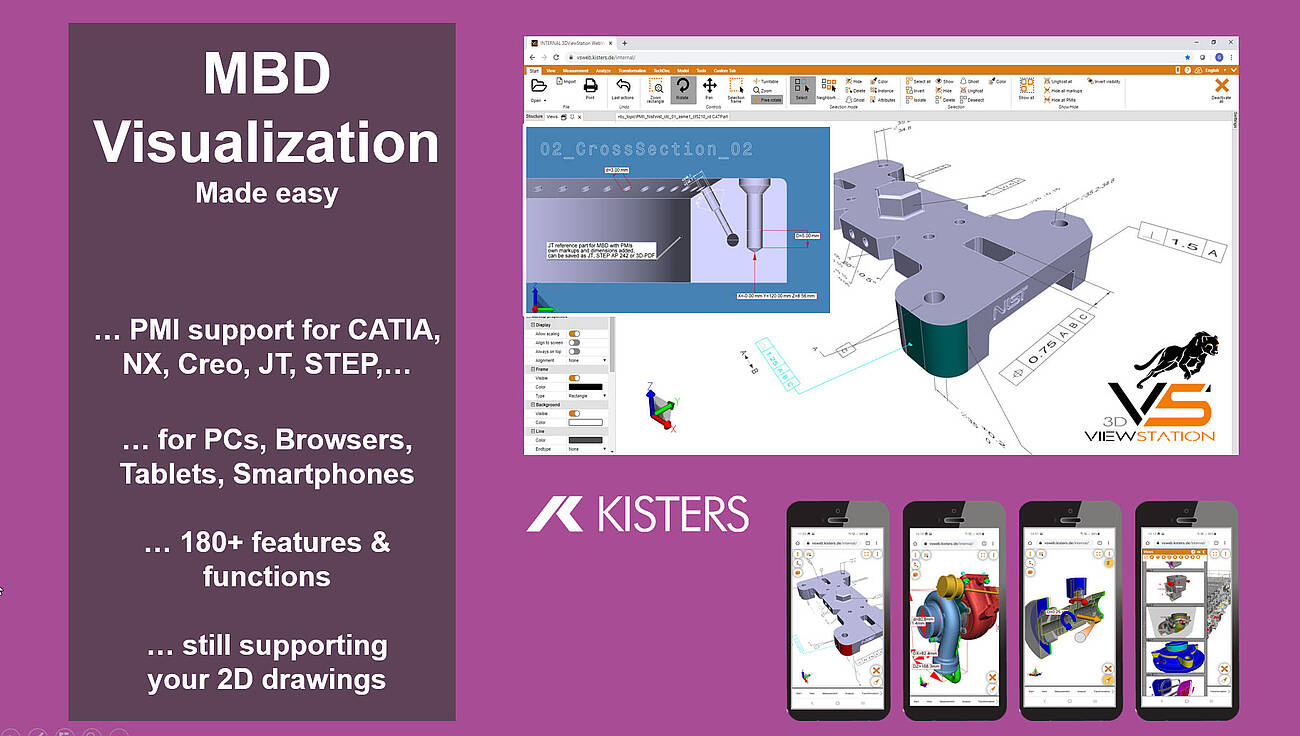

Collaboration basée sur des fichiers vs collaboration en ligne avec le WebViewer de 3DViewStation

| basé sur des fichiers | 3DViewStation (en ligne) | |

|---|---|---|

| pas d'installation client requise | x | √ |

| aucun fichier sur l'appareil (mobile) | x | √ |

| pas de géométries sur l'appareil (mobile) | x | √ |

| pas besoin de joindre des fichiers volumineux | x | √ |

| évite les solutions de contournement pour les pièces jointes trop volumineuses | x | √ |

| évite de télécharger chaque fichier, pas de temps d'attente | x | √ |

| fonctionne avec une taille de fichier pratiquement illimitée | x | √ |

| évite la limitation de taille de fichier typique des visionneuses libres | x | √ |

| affiche les grands modèles en secondes | x | √ |

| les appareils mobiles peuvent afficher des tailles de fichiers pratiquement illimitées | x | √ |

| fonctionne bien avec des fichiers volumineux lors de l'utilisation de connexions de données mobiles | x | √ |

| solution de visualisation évolutive uniquement sur le serveur, pas sur le client | x | √ |

| variantes & configurations : Modification en temps réel | x | √ |

| jumeau numérique : Refléter immédiatement les changements, par exemple "as-maintained" | x | √ |

| accès dynamique aux documents associés en temps réel | x | √ |

| accès à des métadonnées dynamiques et actualisées en temps réel | x | √ |

| les activités des utilisateurs peuvent être suivies | x | √ |

| contrôle total de l'accès aux fichiers | x | √ |

| remplacer les fichiers obsolètes sans les renvoyer | x | √ |

| coopération : Marquages immédiatement disponibles sur le serveur | x | √ |

| une seule visionneuse pour tous les formats de fichiers | x | √ |

| une seule interface utilisateur, même fonctionnement, pour tous les formats de fichiers | x | √ |

| même fonctionnalité pour tous les formats de fichiers 3D et tous les formats de fichiers 2D | x | √ |

| en toute sécurité : Les géométries ne peuvent pas être capturées | x | √ |

La 3DViewStation peut-elle m'aider si je dois collaborer par le biais d'échanges de fichiers ?

Oui, la 3DViewStation vous aide également dans ces cas d'application :

- Premièrement, lorsque vous recevez des fichiers, qu'il s'agisse de modèles CAO 3D ou de dessins 2D, de documents Office ou d'images, la 3DViewStation peut en lire un grand nombre.

- Deuxièmement, si vous devez exporter vers d'autres formats de fichiers, par exemple des formats de fichiers neutres 3D ou 2D, la 3DViewStation et notre outil de traitement par lots KAS peuvent également vous aider.

Veuillez consulter notre liste de formats de fichiers pris en charge , qui répertorie les formats de fichiers 3D et 2D que nous pouvons importer ou exporter.

What do I need to know when translating a 3D-CAD model into another neutral 3D file format?

We think, that there are several important considerations to keep in mind, like file format selection, model structure, views, annotations, metadata and more:

So first of all, we need to choose an appropriate neutral 3D file format for the translation. The most important neutral BREP file format for sure is STEP (Standard for the Exchange of Product Data). Here typically AP 214 and AP 242 are used. In the automotive industry JT has become an important standard. Less important, but still used is IGES (Initial Graphics Exchange Specification). Finally there are several rather simple tessellation based file formats like STL (Standard Tessellation Language), VRML (Virtual Reality Modelling Language) and OBJ, see also our complete file format list, section export 3D. The specific format you choose will depend on the requirements of the receiving software or system. BREP based file formats are intended to exchange between CAD systems, while tessellation based file formats are good for many visualization needs.

In most cases we need to take into account the structure and hierarchy of the original CAD model and how it will be translated into the neutral file format. CAD models often have an organized structure with components, assemblies, and sub-assemblies. Ensure that the translation process maintains this structure for better organization and future editing or manipulation. Be aware, that some file formats do not support the structure and hierarchy.

Many 3D-CAD systems support so called captures or PMI views, which are all called views in the 3DViewStation world. As not all file formats support such views, you we might have to select the right one, if we need to retain them.

If your enterprise follows the MBD concept (Model Based Definition, also called 3D Master), then you replaced 2D drawings by 3D annotated models. Translating such files requires a target file format, which will support PMIs (Product Manufacturing information). STEP AP 242 and JT are such file formats. When using Kisters 3DViewStation or KAS in order to translate these files, you need to ensure, that the correct import and export settings have been set.

Today it is very important to preserve metadata, attributes, and properties associated with the CAD model, such as material information, part numbers, or custom properties during the translation process. Be careful: Some formats may support metadata transfer, while others may require additional steps or custom scripting, some file formats might not even support any.

We, the visualization experts, are aware of how visual properties, such as colors, textures, or surface finishes, will be handled in the translation process. Some neutral file formats may support these visual attributes, while others may require additional steps or settings to preserve or recreate the desired appearance in the target application.

We also need to understand the level of geometry accuracy and detail required for the translation. Different file formats may handle geometry representations differently, such as using NURBS (Non-Uniform Rational B-Splines) or polygonal mesh representations. Consider the level of precision and detail needed for your intended application and ensure the chosen file format supports it.

We need to confirm that the units and scale of the original CAD model are correctly preserved during the translation. This is crucial to ensure dimensional accuracy and proper scaling in the resulting neutral file format. Verify that the translated model aligns with the intended unit system and scale in the target application.

In case we know the target system we do have a chance to understand the compatibility and limitations of the target software or system with the chosen neutral file format. Different software packages or systems may have varying support or interpretation of specific file formats. Ensure that the target application can correctly read and interpret the translated file for optimal compatibility and usability. We can help selecting the most promising file format depending on the target system.

While KAS allows to translate file in batch mode, you can use 3DViewStation Desktop or WebViewer version to do these translations manually. But they are also good to review the translated model to confirm its accuracy and integrity. Check for any errors, missing geometry, or unexpected changes that may have occurred during the translation process. There are also quality checkers available on the market, which might be used before forwarding the file or before importing them into the target system.

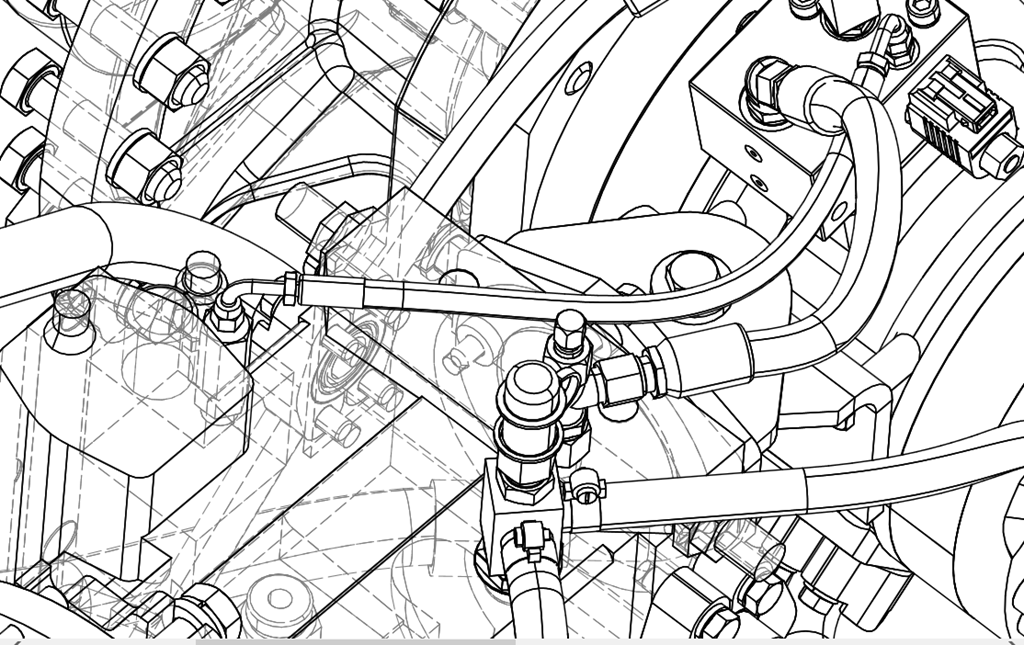

What do I need to know when exporting from a 3D-CAD model to a 2D vector file?

Determining the appropriate file format for the vector file is key. In the manufacturing industry common file formats used for 2D drawings include 2D DXF (Drawing Exchange Format), 2D PDF (Portable Document Format) and SVG (Scalable Vector Graphics). Sometimes the file format required depends on the target application and system, where it will be used.

Organize your CAD model into appropriate layers and/or blocks before exporting. This allows for better control over different components, annotations, or visual elements in the vector file. 3DViewStation APIs and our batch tool KAS allow to automatically build layers and blocks, based on the product structure of the 3D-CAD model.

Familiarize yourself with the export settings and APIs provided by 3DViewStation and KAS. These settings may include options for curve smoothing, resolution, and compatibility with different software or devices. Decide whether you want to include hidden lines in the exported vector file or show only visible lines. Depending on the purpose of the 2D representation, you may need to enable or disable hidden line removal to accurately represent the design.

3DViewStation and KAS can help you simplifying or optimizing the geometry of your 3D CAD model before exporting to a 2D vector file. They allow to remove unnecessary details, such as internal components or hidden features, to keep the resulting vector file clean and lightweight. This can help improve performance and reduce file size.

Consider the desired level of quality and precision in the exported vector file. This relates to the smoothness of curves, accuracy of angles, and overall detail. Higher quality settings may result in larger file sizes, so balance your requirements with file size considerations. Very often it is crucial to keep file size as small as possible, which requires intelligent vectorization and compression algorithms, like 3DViewStation and KAS provide.

We need to ensure that the dimensions of your 3D model are accurately translated to the 2D vector file. Check the scaling and units of measurement to avoid any discrepancies. File formats like PDF know their paper size, which might make it easier to retain the intended scale during the conversion.

Leveraging 3DViewStation Desktop or WebViewer version you can verify that the exported vector file represents the desired geometry and level of detail. Pay attention to curves, arcs, and splines, as they may require higher resolution or special settings to maintain smoothness.

Some file formats do support line thickness and styles. As 3D CAD model do not have any settings like that, we’ll need to specify them in such a case. Different software may handle linework differently, so be prepared to adjust these settings during the export process.

3DViewStation and KAS will care for colors and fills automatically, depending on black & white or color setting: You can assign specific colors to different layers or components, interactively or via API or opt for a monochromatic representation during export.

Finally, if your 3D CAD model includes 3D annotations, labels, dimensions, balloons, tables or text blocks, verify that they are appropriately exported and legible in the 2D vector file. These annotations are essential for conveying important information about the design and can aid in manufacturing or construction processes.