Sacramento, CA – March, 15th, 2019 – Project managers and sales representatives in the tool making, casting, mold/die and plastic injection industry regularly respond to requests from customers inquiring about the cost of producing a specific part. The part must be inspected and analyzed to draw these conclusions and supply an answer. What is the most efficient software tool for this purpose? KISTERS 3DViewStation provides an easy-to-use, affordable visualization and inspection application that assists users, enterprise-wide in this process.

The typical, basic functionalities needed to support the inspection and analysis processes are: the loading of native CAD files, volume calculations, measurements, dimensions, sectioning, and annotations. In addition, companies often need the ability to isolate and inspect parts in order to perform a more advanced analysis. With 3DViewStation, the result of this work can be organized into views and easily saved for later retrieval.

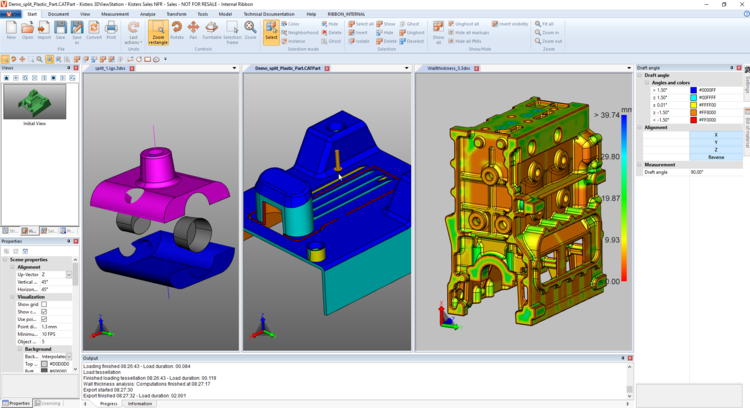

“There seems to be a common misconception that industry-specific analysis functions are only available in a CAD system. However, 3DViewStation, a fast and extremely easy-to-use software product, provides these functions at a much lower price point.” said Tammy Pleasent, KISTERS North America Sales Manager. “One typical industry-specific required functionality is: draft angle analysis, which assists in the identification of undercuts. In addition, we have recently added a splitting function that helps determine the complexity of the required tool in order to unmold the produced part. This can be combined with draft angle analysis, providing your business a multitude of tools to assist throughout the entire molding process.”

“Complementary functions for this process are our real time wall thickness measurement, projected area calculation and analysis of the complete part, which shows its results by color coding the object and supplying an easy-to-decipher color key.” she added. “These advanced functions are available in our Desktop version and WebViewer product. Therefore, you can access these tools in both a stand-alone or integrated environment on any leading system (such as an: ERP, MES or PLM system) by leveraging our high level APIs.”

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including i.e. Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

The latest developments of 3DViewStation can be reviewed in more detail at: https://www.3dviewstation.com/blog.html.

According to Pleasent, the KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, ActiveX, VR-Edition and HTML5 WebViewer product-versions. All product flavors are intended to be used together with a PLM, ERP or other management system product configuration or service and spare part applications, providing all necessary APIs. For cloud, portal and web-solutions, there is an HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address needs of complex integration scenarios.

About the company

25 years success in the market with superior visualization solutions from desktop to mobile has proven KISTERS to be one of the top players in the visualization industry. Clients ranging from small firms to well-known multinationals, 3DViewStation's easy-to-use interface is suitable for all user groups and 100% customizable to each individual’s specific requirements. More than 3,000 customers and over 200,000 installations worldwide. In addition, KISTERS offers expert advice and support in concept development based on client requirements.

Contact:

KISTERS

www.3dviewstation.com

sales-viewer(at)kisters.net